CNC Machining Tolerances Explained: From ±0.01 mm to ±0.001 mm?

Problem: You need CNC parts with tight tolerances—but what’s the real difference between ±0.01 mm and ±0.001 mm?

Agitate: You worry about part rejection, missed fits, and supplier claims that don’t match results.

Solve: This guide explains how tolerance is set, managed, inspected—and how to choose the right level for your application.

Snippet paragraph:

✔️ Learn how CNC tolerance is influenced by machine setup, environment, and material.

✔️ Discover how tooling and calibration ensure repeatable precision.

✔️ See the best inspection methods to verify ±0.001 mm accuracy.

✔️ Compare aerospace vs automotive requirements with real examples.

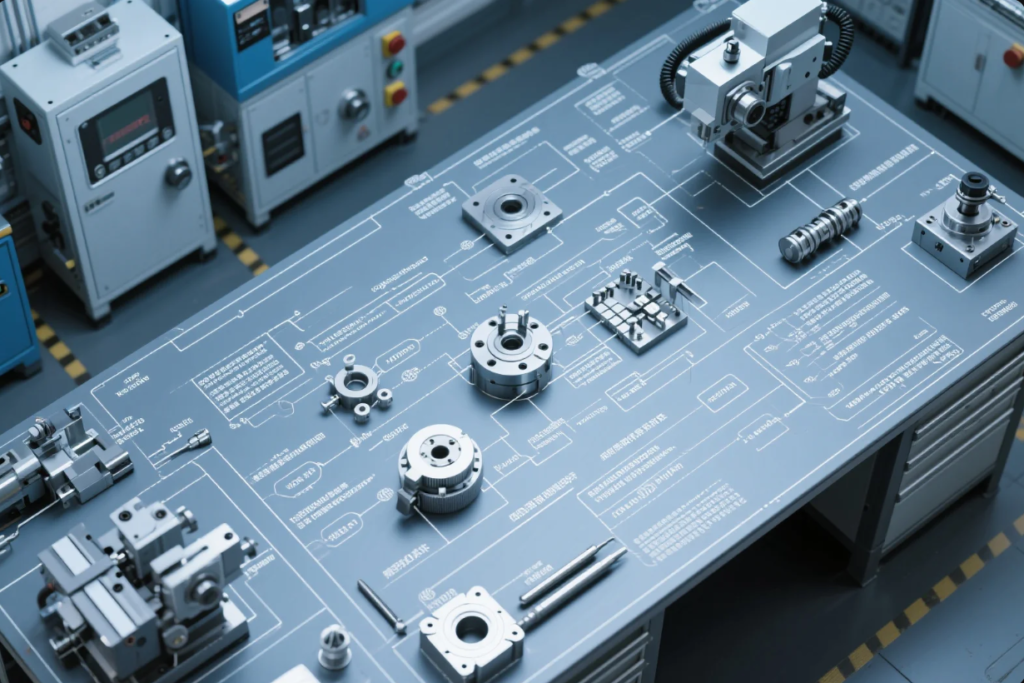

What Factors Control CNC Tolerance Accuracy?

Achieving a CNC machining tolerance of ±0.01 mm is standard. Going tighter—like ±0.005 mm or ±0.001 mm—requires more control.

Key Influencing Factors:

- Machine Rigidity & Repeatability

- Ambient Temperature Control

- Material Expansion Characteristics

- Feed Rate & Spindle Speed

- Fixture and Clamping Stability

| Factor | Risk at ±0.01 mm | Risk at ±0.001 mm | Notes |

|---|---|---|---|

| Temperature change | Low | Very High | Use climate-controlled workshops |

| Operator error | Medium | High | Automation and G-code simulation help |

| Machine brand | Important | Critical | Use ultra-precision VMCs or jig borers |

Read: Controlling Thermal Expansion in CNC

Tooling Design & Machine Calibration Best Practices

High tolerance needs better tooling. Tool stiffness, condition, and balance directly affect accuracy. Calibration ensures machine consistency over time.

Best Practices Include:

- Short, rigid cutting tools

- On-machine probing systems

- Laser calibration (e.g., Renishaw)

- Ballbar diagnostics for backlash

| Technique | Purpose | Tools Used |

|---|---|---|

| Tool presetting | Maintain length/tool offset | Presetter, Z-height gauges |

| Laser calibration | Axis verification | Laser interferometers |

| Warm-up routines | Thermal stabilization | Internal macros or schedules |

Explore: Renishaw Tool Probing Systems

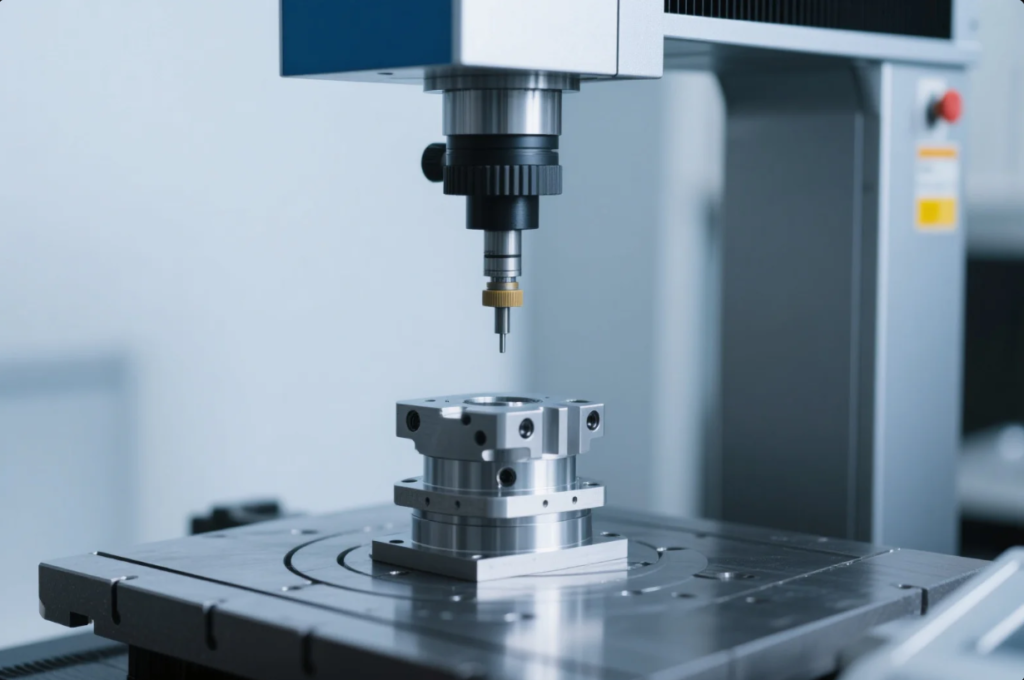

Inspection Methods: CMM, Gauges, First Article Testing

Verification is as important as machining. Here are common ways to inspect high-tolerance parts:

- CMM (Coordinate Measuring Machine): 3D precision, ideal for tight specs.

- Precision Gauges: Fast for bores and shafts, not suitable for contours.

- First Article Inspection (FAI): Used in aerospace/defense for full documentation.

| Method | Tolerance Capability | Ideal Use Case |

|---|---|---|

| CMM | Up to ±0.001 mm | Complex geometry, traceability |

| Gauges | ±0.005 mm | Quick check, production line |

| FAI | All levels | Certification, new projects |

Guide: CMM Inspection – Quality Magazine

Real-World Examples: Aerospace vs Automotive Parts

Aerospace: Maximum Precision

- Tolerance: ±0.005 mm to ±0.001 mm

- Surface: Ra < 0.4 µm

- Full documentation: AS9102, lot tracking, material certs

Automotive: High Volume, Consistent Fit

- Tolerance: ±0.01 mm to ±0.05 mm

- Surface: Ra < 1.6 µm

- Focus: Speed, cost, and repeatability

| Industry | Typical Tolerance | Focus | Inspection Depth |

|---|---|---|---|

| Aerospace | ±0.001 mm | Precision + traceability | 100% dimensional + FAI |

| Automotive | ±0.01 mm | Cost + cycle time | Spot-check + SPC |

PPAP Guide – AIAG

AS9102 Overview – SAE

FAQs

Q1: What’s the difference between ±0.01 mm and ±0.001 mm?

±0.001 mm is 10x tighter. It’s used where micro-alignment is critical.

Q2: Can all shops deliver ±0.001 mm?

No. Only climate-controlled, precision CNC factories can do this reliably.

Q3: Is CMM required for tight tolerances?

Yes. Manual gauges lack the resolution needed for ±0.001 mm.

Q4: What industries require ±0.001 mm?

Aerospace, medical devices, optics, and sensors.

Q5: Does tighter tolerance cost more?

Yes. More setup, slower cutting, and full inspection are needed.

Q6: Can I see a sample inspection report?

Yes. Always request one before approving production.

Conclusion

Understanding CNC tolerances—from ±0.01 mm to ±0.001 mm—is essential. You now know what affects it, how to inspect it, and when to specify tighter limits.

✅ At Prime, we offer:

- ISO 9001 & AS9100-certified CNC machining

- CMM reports for all tolerance levels

- Expert consultation to help you specify the right tolerances

- Fast quoting and global delivery

📧 Get your quote now: [email protected]

🌐 Visit us: https://primecustomparts.com

Choose Prime—where tolerance meets trust.