CNC Workflow Optimization: From Jogging to Run Mode?

Problem: CNC operators often struggle with switching from manual setup to automated production.

Agitate: This leads to crashes, wasted material, and delayed delivery.

Solve: This guide explains each CNC mode—Jog, MDI, Auto—and how to optimize your workflow safely and efficiently.

Snippet paragraph:

✔️ Learn the difference between Jog and Run modes.

✔️ Follow safety best practices during manual jogging.

✔️ Understand dry run simulations before full production.

✔️ Master MDI, Auto, Edit, and Zero-Return functions to boost efficiency.

Jog vs Run: Manual Setups & Auto Production Explained

Jogging allows manual axis movement for setup. Run mode executes full G-code programs for production.

| Mode | Purpose | Operator Role | Risk |

|---|---|---|---|

| Jog | Manual setup | Touch-off, zeroing | Tool or vise crash if mishandled |

| Run | Automated machining | Monitor production | Incorrect offsets, program errors |

Safe Jogging Protocols and Speed Increments

Always start with slow increments and single-axis movements.

| Axis | Safe Increment | Use Case |

|---|---|---|

| Z-Axis | 0.01 mm | Tool touch-off |

| X/Y-Axis | 0.01–0.1 mm | Edge finding |

| Rotary | Manual/slow | Angle alignment |

Best practices:

- Hand on E-stop

- Never jog blindly

- Confirm offsets before moving Z

Transitioning from Dry Run to Full Production

Dry runs simulate toolpaths to prevent damage.

| Step | Why It Matters |

|---|---|

| Activate dry run | Disable spindle & coolant |

| Raise Z offset | Prevent accidental cuts |

| Monitor paths | Look for collisions or missing code |

| Pause for tool check | Confirm length & clearance |

Use block-by-block mode for your first run.

Dry Run Best Practice – CNC Cookbook

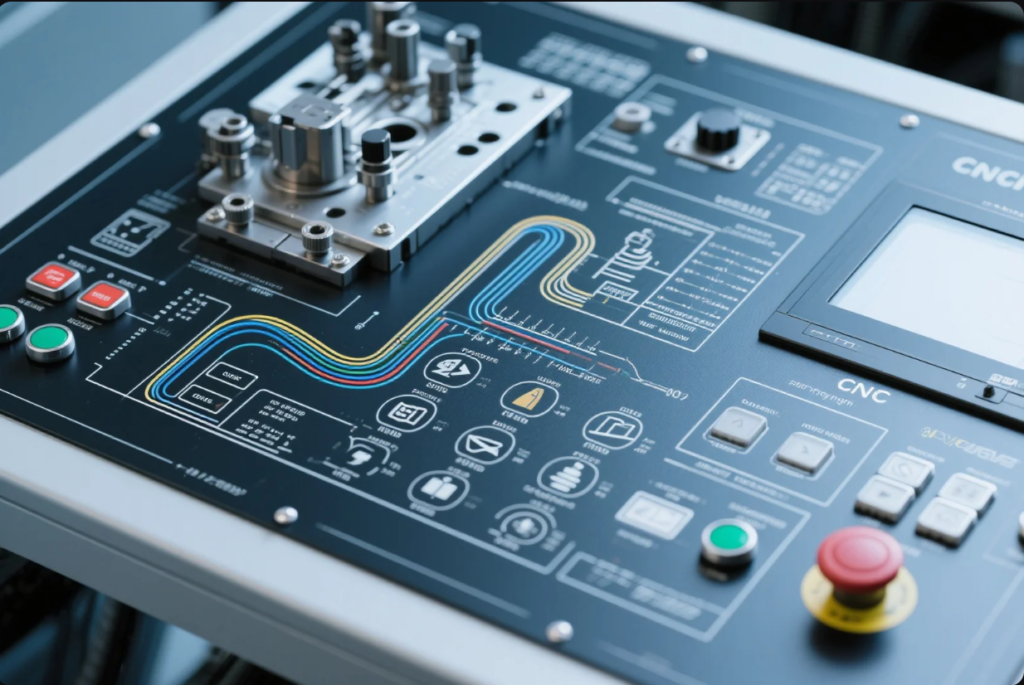

Improving Efficiency: MDI, Auto, Edit, Zero-Return

Knowing when to use each mode saves hours of setup time.

| Mode | Function | Best Use |

|---|---|---|

| MDI | Manual G-code line | Spindle, jog, coolant checks |

| Auto | Run full program | Production |

| Edit | Modify code | Correct G-code or feedrates |

| Zero-Return | Send axes home | Before tool changes or restarts |

Example:

Use M03 S1500 in MDI for spindle warm-up.

Understanding CNC Modes – CNCCookbook

FAQs

Q1: Jog vs MDI?

Jog = manual movement. MDI = manual command.

Q2: Is dry run optional?

No. Always perform a dry run before cutting.

Q3: When to use Zero-Return?

Daily, and after any E-stop or tool change.

Q4: Can I edit G-code during Auto?

No. Switch to Edit mode first.

Q5: Is MDI dangerous?

Yes if you enter the wrong code. Always double-check.

Conclusion

Understanding and correctly using CNC modes—Jog, MDI, Auto, Edit, Zero-Return—can drastically improve your shop’s output, reduce risk, and increase safety.

At Prime, we deliver:

- Trained CNC teams for full workflow support

- Safe, fast, and certified production cycles

- ISO 9001-approved operations with full inspection

📧 Contact us for CNC setup support or rapid quoting:

Email: [email protected]

Website: https://primecustomparts.com

From setup to spindle on—we help you run smarter.