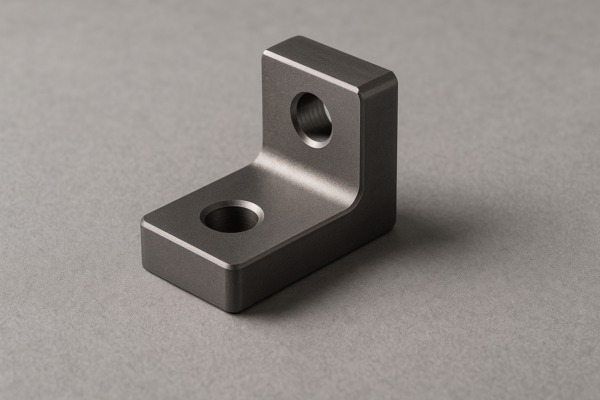

Custom Metal Casting Parts: How to Choose the Right Process for Your Project?

Making the right casting decision prevents quality loss and missed deadlines.

Each casting method has clear advantages. Sand casting offers flexibility. Die casting ensures consistency. Investment casting provides precision. Choose based on part design, volume, and cost.

Selecting a poor method increases scrap rates and delays production. This guide helps you avoid those risks and find the right solution.

Sand Casting vs. Die Casting: Which Is Better for Your Parts?

Choosing between sand and die casting can be confusing if you’re new to industrial metal parts.

Sand casting is best for complex shapes and small production runs. Die casting is ideal for large volumes with high repeatability.

At Prime, we often guide customers through the tradeoffs. A customer from Texas needed 500 aluminum motor housings. Initially, they chose die casting, but the tooling cost was too high. After consultation, we switched to sand casting and saved them over \$12,000 in setup costs.

Comparing Performance Metrics

| Criteria | Sand Casting | Die Casting |

|---|---|---|

| Mold Material | Sand (reusable) | Steel die (expensive but durable) |

| Tooling Time | 5–7 days | 3–4 weeks |

| Tolerance | ±0.5 mm typical | ±0.1 mm typical |

| Best for Metals | Iron, Steel, Bronze, Aluminum | Zinc, Aluminum, Magnesium |

| Surface Roughness | 12.5–25 Ra | 3.2–6.3 Ra |

| Quantity per Run | 1 to 10,000 | 10,000+ |

For engineering data, refer to Thomasnet’s sand casting guide and DieCastingDesign.org for standards in high-pressure casting.

When to Choose Sand Casting

- You need a low-cost prototype

- Part is too large for die casting

- You require flexible material choices

When to Choose Die Casting

- Tolerance is critical

- Volume exceeds 20,000/year

- You want to minimize machining

Prime supports both casting routes. With in-house mold production and CNC finishing, we deliver turnkey casting solutions with excellent cost control.

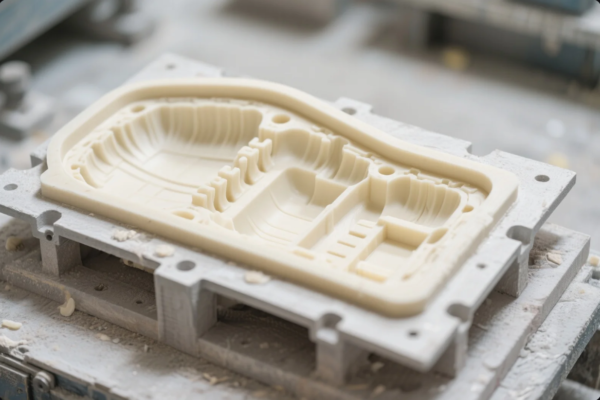

What Is Investment Casting and When Should You Use It?

Have you ever needed precision, but machining was too costly?

Investment casting delivers excellent dimensional control. It uses wax patterns and ceramic molds to create highly detailed parts.

This process works well when you need tight tolerances, complex shapes, or smooth finishes without too much machining. At Prime, we offer investment casting for clients in medical, aerospace, and tool manufacturing.

Compared with other methods, this technique supports stainless steel, tool steel, Inconel, and more. Using Hitchiner Manufacturing’s definition: "It’s one of the oldest known metal-forming techniques, now supported by modern materials and controls."

We once helped a European client reduce post-processing by 40% using this method. Thanks to digital simulation and ceramic slurry refinement, their rejection rate dropped by 25%.

Features of Investment Casting

| Attribute | Value for Buyer |

|---|---|

| Surface Finish | Excellent, RA < 6.3µin |

| Wall Thickness | As low as 0.5mm |

| Casting Weight | 10g to 30kg typical |

| Volume | Medium runs ideal |

| Cost per Part | Higher than sand casting, but lower finishing cost |

For more background, see MetalTek’s investment casting page or AZoM’s casting guide.

How to Minimize Defects in Custom Metal Castings

Casting flaws are expensive. They ruin structural integrity and increase scrap.

You can minimize them with proper gating, gas venting, and post-process inspection.

The most common defects include:

- Porosity (due to gas entrapment)

- Cold shuts (due to poor fluidity)

- Shrinkage cavities (from insufficient riser design)

At Prime, we prevent such defects using:

- Mold flow simulation tools like MAGMASOFT

- Non-destructive testing (UT, X-ray, dye penetrant)

- Heat treatment for stress relief

ASNT offers more insight into non-destructive testing standards, while TotalMateria explains common casting flaws in detail.

Our quality team works in three shifts, using laser scanning, CMM, and tensile testing. This allows us to guarantee defect rates below 0.3%.

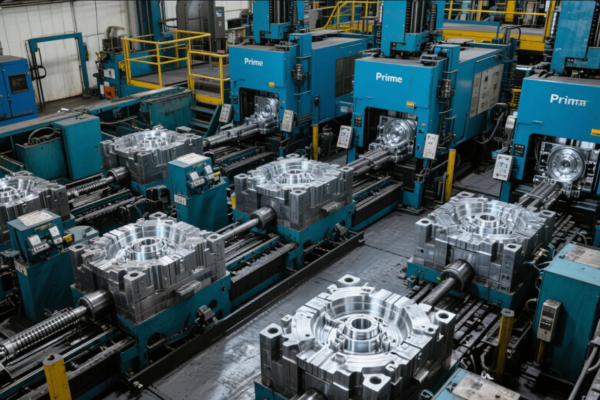

Lead Times and Cost Considerations for Different Casting Methods

Many buyers underestimate how casting type impacts total delivery time.

Sand casting has the shortest lead time. Die casting needs more upfront tooling. Investment casting requires precision shell building, which takes time.

A UK-based tool company once needed 3,000 pieces urgently. They asked for investment casting, but we showed them how sand casting with CNC post-finishing could deliver faster at lower cost. The client received parts within 18 days, well before their product launch.

Estimated Lead Time Comparison

| Casting Type | Lead Time | Ideal Volume | Upfront Tooling Cost |

|---|---|---|---|

| Sand Casting | 2–3 weeks | 1–5,000 units | Low |

| Die Casting | 4–6 weeks | 10,000+ units | High |

| Investment Casting | 3–5 weeks | 500–10,000 | Medium |

Sources like GlobalSpec and Matmatch offer more industry comparisons.

Prime uses flexible capacity to prioritize urgent orders. Our internal ERP monitors 10 casting lines, allocating jobs by complexity, not just order time. We also offer free samples for most high-volume projects, helping clients avoid production delays.

FAQs on Custom Metal Casting

What casting method is best for aluminum?

Die casting is ideal for high-volume aluminum parts. For smaller runs, use sand or investment casting.

Can Prime help with design improvements?

Yes. Our engineers offer DFM suggestions, simulation reports, and cost breakdowns during quoting.

Do you offer finishing like anodizing or powder coating?

Yes. We provide surface treatment, CNC trimming, thread tapping, and heat treatment as needed.

What is your minimum order quantity (MOQ)?

We handle custom orders as low as 100 pcs, depending on the part complexity.

Do you provide export-compliant packaging?

Yes. All shipments follow export-grade foam, wooden crate, or vacuum seal, as required.

How can I get a quote?

Just send your PDF or STEP file, target quantity, and material spec to [email protected].

Conclusion and Contact Information

Choosing the right casting method helps you lower costs, avoid defects, and speed up delivery. Let Prime be your trusted B2B casting supplier.

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com

We provide free technical consultation, detailed quotes, and rapid sampling for global buyers.