Custom Sheet Metal Parts: The Ultimate Guide from Design to Delivery

Introduction: Why Custom Sheet Metal Parts Matter

Delayed custom parts cause missed launches and cost overruns. According to the Manufacturing Institute, over 70% of manufacturers struggle with sourcing reliability.

As a global supplier since 1993, I’ve worked with hundreds of industrial clients. Whether you’re scaling new machinery or prototyping a bracket, understanding each step—from design to delivery—can cut lead time and ensure product quality.

This guide helps you:

- Select the right material

- Set tolerance expectations

- Understand forming processes

- Speed up prototypes

- Avoid communication gaps

How Custom Sheet Metal Parts Meet Industry-Specific Precision Standards

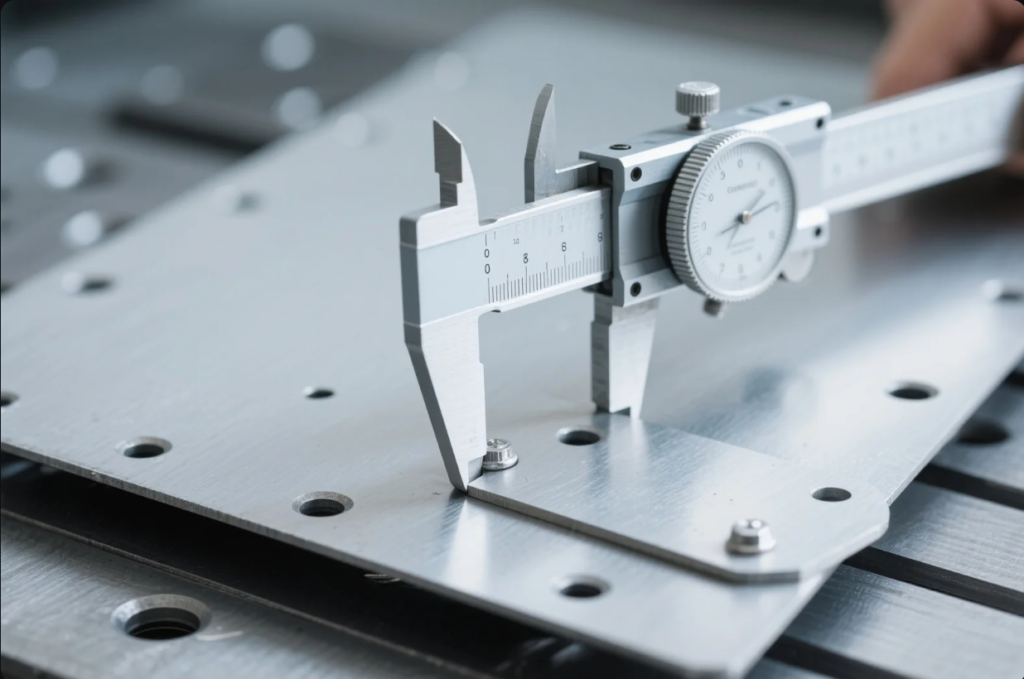

Precision affects assembly, safety, and long-term function. However, many buyers fail to define tolerance in RFQs, risking poor fit.

Why Tolerances Matter

- Automotive: ±0.10 mm

- Aerospace: ±0.05 mm

- Electronics: ±0.20 mm

Defined by ISO 2768, these tolerances reduce risk when matched with the right process.

Read more in Engineering.com’s tolerance guide and The Fabricator.

How We Control It at Prime

| Stage | Tool / Method | Benefit |

|---|---|---|

| Material Check | Digital micrometer | Verifies sheet thickness |

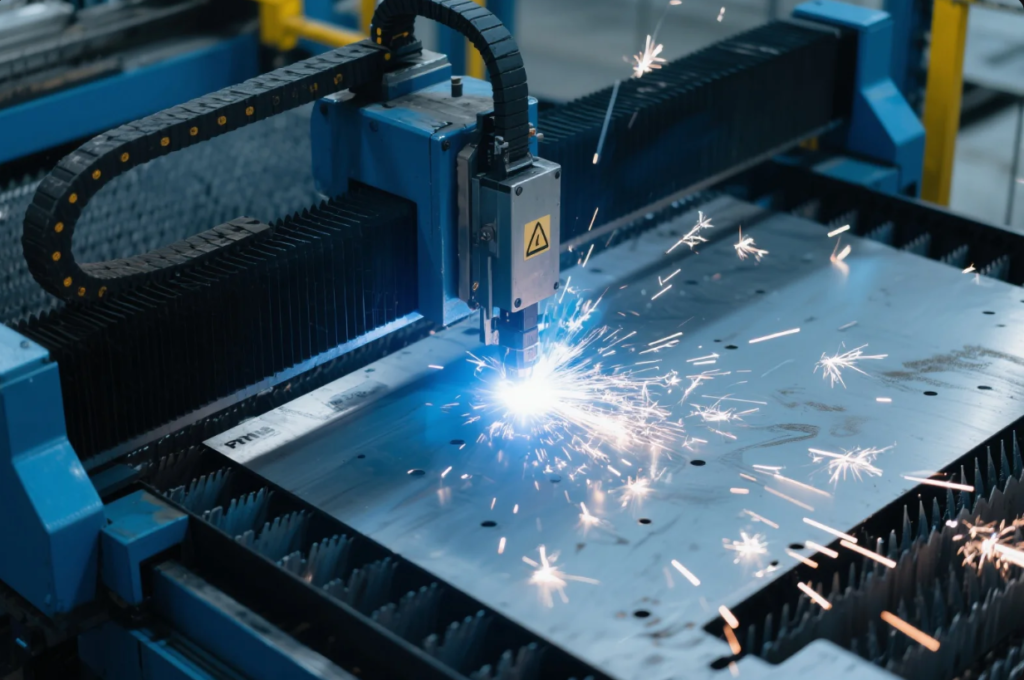

| Laser Cut | ISO 9001-certified CNC lasers | Precise and clean cuts |

| Bending | Servo press brake | ±1° angle tolerance |

| Final Inspection | CMM + digital caliper | Confirms all key dimensions |

See more from ISO 9001 and SAE International.

Choosing Between Steel, Aluminum, and Stainless Steel

Material selection impacts weight, strength, finish, and cost.

Key Differences

| Material | Strength | Weight | Corrosion Resistance | Cost |

|---|---|---|---|---|

| Carbon Steel | High | Heavy | Needs coating | Low |

| Aluminum (6061) | Medium | Light | Naturally resistant | Medium |

| Stainless (304) | High | Heavy | Excellent | High |

Consult databases like Total Materia or ASM International.

Finishing Options

- Steel: Powder coating, zinc plating

- Aluminum: Anodizing

- Stainless: Passivation

See AWS Welding Handbook for joint prep and gas compatibility.

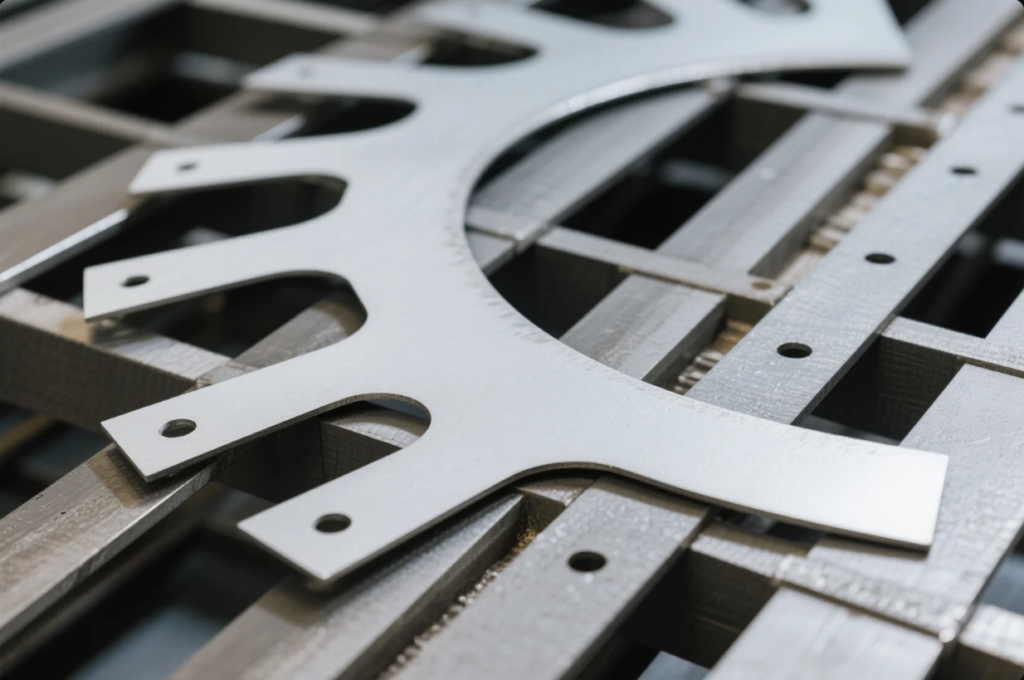

Key Fabrication Processes: Laser Cutting vs. Bending vs. Stamping

Each process suits a different stage of production.

Process Overview

| Process | Use Case | Precision | Setup Cost |

|---|---|---|---|

| Laser Cutting | Prototypes, short run | ±0.05 mm | Low |

| CNC Bending | Frames, panels | ±1° | Medium |

| Metal Stamping | Mass production | ±0.05 mm | High |

Explore more in The Fabricator’s comparison.

Hybrid Strategy

Prototype with laser; scale with stamping.

- Low initial cost

- Flexibility in design changes

- Lower unit cost at volume

See DFM Guidelines to prepare for stamping success.

Tips for Faster Prototyping and On-Time Delivery

Fast delivery requires clear drawings, fast feedback, and tight logistics.

Workflow Steps

- Submit 3D files (.stp, .igs, .dxf) – Autodesk explains why

- Receive quote within 48h

- Prototype in 5–7 days

- Production in 7–10 days

- Shipping in 5–10 days (DHL, FedEx, UPS)

Total: 22–30 days from inquiry to delivery.

Packaging tips: Export packaging for industrial goods

FAQs: Common Questions from Buyers

What formats do you accept?

STEP (.stp), IGES (.igs), DXF

Can I order a sample?

Yes, starting from 10 pcs.

Are you ISO-certified?

Yes, ISO 9001 since 2005. See ISO database.

Do you ship worldwide?

Yes. USA, Europe, Middle East, Asia-Pacific.

Are your finishes RoHS/REACH compliant?

Yes. See RoHS guidelines

What’s the payment method?

T/T, PayPal, L/C (large orders).

Contact Prime: Get Your Free Quote Today

I’m Kevin, and I manage sourcing for clients worldwide. With Prime, you’ll get:

- 48-hour quotes

- ISO-backed quality

- Rapid prototyping

- Worldwide delivery

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com/

Let’s get your next project manufactured—accurately and on time.