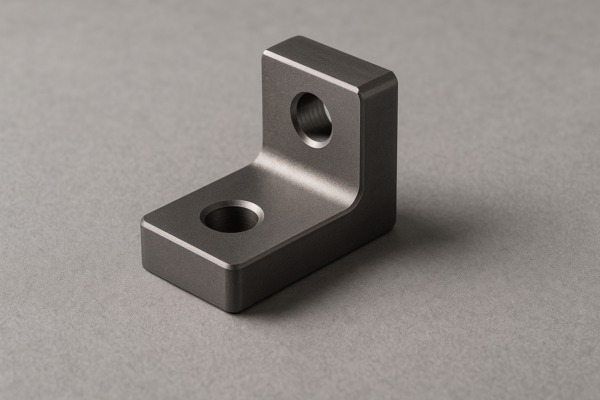

Custom Stainless Steel Casting Parts: What Should You Check Before Ordering?

Vague specs cause delays, scrap, and leaks. Stainless steel casting1 behaves differently from machining or forging. I explain how to pin down process, tolerances2, alloys, finishes, and tests so your parts pass inspection on the first lot.

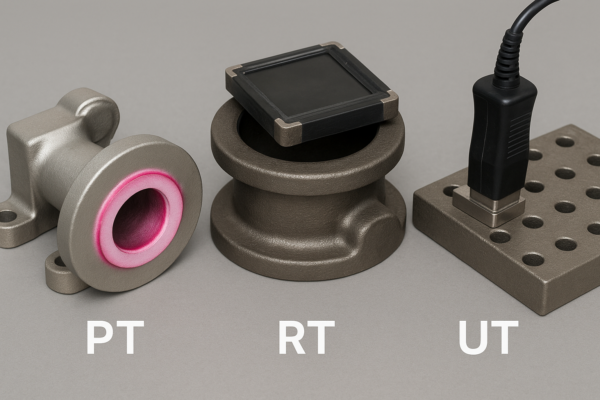

To order stainless steel castings correctly, define process (investment/shell/sand), ISO 8062-3 tolerance class1, alloy (e.g., ASTM A351 CF8/CF8M), heat treatment (solution anneal), surface finish (Ra), and inspection (PT/RT/UT to ASTM). Add passivation per ASTM A9672 and request FAI/CMM plus packaging details for safe delivery.

Next, I break down the process, compare techniques, and map applications so your RFQ gets apples-to-apples quotes1 and fewer change orders2.

Understanding the Stainless Steel Casting Process?

Poorly defined routes create porosity, warp, or dimensional drift. Clear standards, heat treatment1, and inspection keep castings consistent2.

Stainless casting converts a pattern to a near-net metal shape, then heat treats, finishes, and verifies. Use ISO 8062-31 for casting tolerance grades, call out alloy per ASTM A3512 (CF8 ≈ 304, CF8M ≈ 316), specify solution anneal, passivation to ASTM A967, and NDT (PT/RT/UT) to relevant ASTM practices for measured quality.

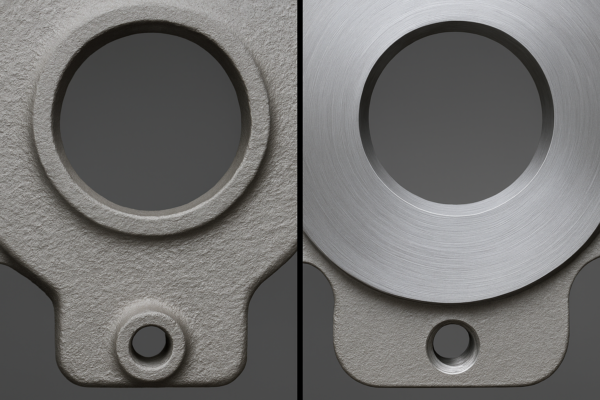

From a buyer’s seat, I plan the full route up front: pattern selection (wax/printed/sand), gating/risers, pour, knockout, heat treat, finish, and inspection. For austenitic grades (CF8/CF8M), I specify solution anneal1 to restore corrosion resistance; quenchant depends on section size and alloy. I assign ISO 8062-3 CT grades2 early—investment often targets CT4–CT6; sand is looser (CT8–CT12). I set functional as-cast tolerances (e.g., ±0.30 mm / ±0.012 in on small investment features, increasing with length) and a surface plan: as-cast faces at \~3.2 µm Ra for investment; sealing faces machined to \~1.6 µm Ra.

Upload your drawing for a 24-hour DFM1; I’ll mark gating, draft, and wall transitions2 to hit tolerance and finish efficiently.

Practical checkpoints buyers should verify

- Confirm alloy callout (ASTM A351 grade1) and heat treatment note.

- Specify ISO 8062-3 tolerance class2 and GD\&T datums/features.

- Define NDT scope (PT/RT/UT), acceptance levels, and sampling.

Quality & packaging notes buyers care about

- Require passivation (ASTM A9671) and PMI records per heat.

- Request FAI/CMM with ballooned print and GR\&R on critical gauges.

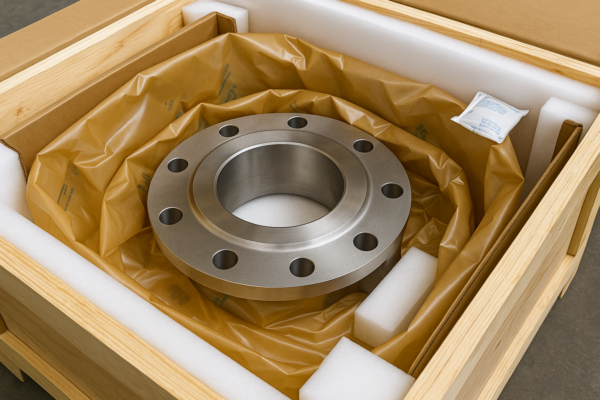

- Use VCI + desiccant + foam-lined crates; protect threads and edges.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Material/Grade | CF8 (≈304) | CF8M (≈316)1 | CF8M higher chloride resistance2; slightly higher cost. |

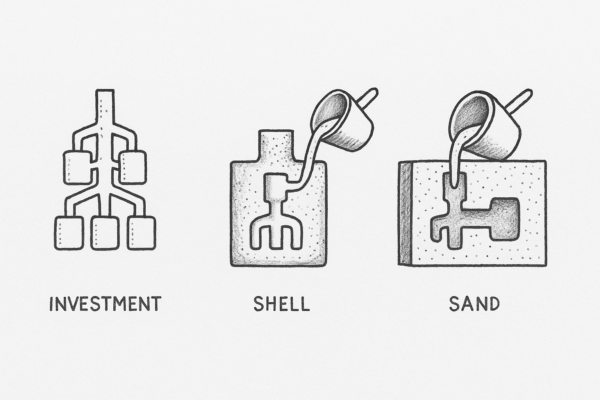

Common Techniques for Stainless Steel Casting?

Choosing the wrong method inflates cost1 or misses tolerance. Match geometry, volume, finish, and alloy behavior2 to the process.

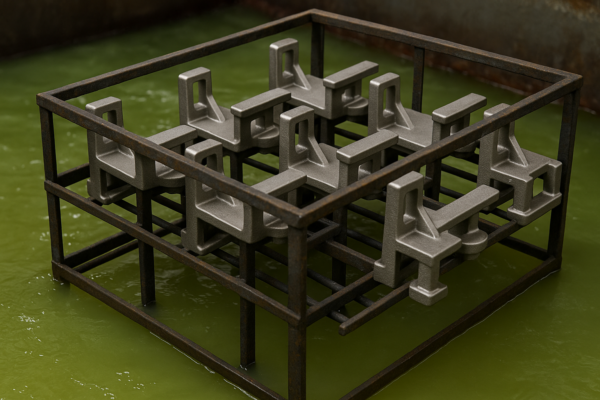

Investment casting (silica-sol) gives the best as-cast accuracy (often CT4–CT6) and smoothest Ra. Water-glass investment lowers cost with rougher Ra. Shell molding offers mid-accuracy for medium runs. Green/resin sand fits large shapes with looser CT grades. Define minimum walls, draft, and parting early for success. (See ISO 8062-3.)

I separate four mainstream routes for stainless:

1) Investment casting (silica-sol shell)1. Best for thin walls, complex details, and cosmetic surfaces. Commonly achieves CT4–CT62 with \~3.2 µm Ra. Tooling is moderate; multi-cavity tools compress piece price at volume. 3D-printed wax patterns can accelerate first articles.

2) Investment casting (water-glass shell). Cheaper shell chemistry, faster shell build, but rougher finish (\~6.3–12.5 µm Ra) and looser tolerance; good where post-machining dominates.

3) Shell molding1. Resin-coated sand shells give cleaner surfaces and tighter dimensions than green sand; good for medium volumes and repetitive accuracy on mid-size features.

4) Sand casting (green/resin). Lowest tooling cost and widest size range. Looser CT8–CT12 tolerances and rougher surfaces require larger machining allowances. For pumps and housings, I often pair sand for bodies and investment for impellers to balance price and performance.

At Prime (China)—founded 1993, ISO-certified1, 10 production lines—I share DFM before tooling: minimum walls (≥2 mm investment; ≥4–6 mm sand), uniform sections, fillets for flow, and balanced gating. I highlight draft and parting to reduce post-grind. I also define inspection by wall thickness2: PT on all critical surfaces, RT with acceptance pictures (ASTM E446/E186/E280), and UT per A609 where section types merit it.

Upload your print; I’ll recommend the lowest-cost process1 that still meets your GD\&T and finish, with a 24-hour quote2.

Practical checkpoints buyers should verify

- Assign CT grade1 per feature/process (e.g., CT5 for investment seat, CT9 for sand boss).

- Set finish by function2: Ra ≤3.2 µm for seals; rougher allowed on non-critical faces.

- Lock draft angles, parting lines, and minimum wall thickness per process window.

Quality & packaging notes buyers care about

- Specify radiography level by section (reference ASTM E446/E186/E280 images).

- Add UT per ASTM A6091 for martensitic/duplex webs or high-stress zones.

- Use racked, foam-spaced packaging2 to protect edges/threads; include torque-cap protectors.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Investment Shell | Silica-sol1 | Water-glass | Silica-sol1 = tighter CT/finish, higher shell cost; water-glass = cheaper, rougher. |

| Process | Shell molding2 | Green/resin sand | Shell improves accuracy & Ra; sand lowers tooling for large parts. |

| Finish Plan | As-cast Ra ≈3.2 µm | Machine critical faces1 | Machining improves sealing, adds cycle time. |

| NDT Scope | PT only | PT + RT/UT | More coverage lowers defect risk; increases lead time. |

| Tooling | Single-cavity | Multi-cavity/family | Multi-cavity reduces unit cost2; higher upfront tool cost. |

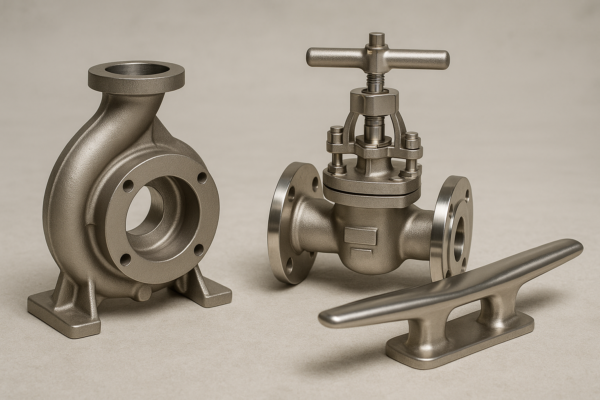

Applications of Cast Stainless Steel Products?

Right shape, wrong alloy1 still fails. Match media, temperature, and load to a grade and test plan2.

CF8 (≈304) fits general duty. CF8M (≈316) adds 2–3% Mo for pitting resistance1—common in valves, pumps, food, and marine fittings. Duplex cast grades under ASTM A995/A8902 (e.g., CD4MCuN) raise strength and chloride stress-corrosion resistance. Specify solution anneal, passivation (A967), and NDT matched to risk.

Here’s how I map alloys to jobs. General industrial brackets, housings: CF8 is economical, weldable, and adequate in mild environments. Chemical, food, and marine wetted parts: CF8M’s molybdenum improves pitting resistance1; it’s my default where chlorides or washdowns exist. Erosive slurries, seawater pumps, high pressure: Duplex grades (e.g., CD4MCuN, ASTM A995 4A)2 deliver roughly 2× the yield of austenitics with better chloride SCC resistance, often allowing wall reduction and weight savings.

Typical A351 mechanical minima (check alloy table in your PO): tensile \~485 MPa (70 ksi), yield \~205 MPa (30 ksi), elongation 30–35% for CF8/CF8M; duplexes run higher but require careful heat treatment and ferrite balance (per A9951). Media, temperature, and chloride ppm drive the choice; I ask for these in the RFQ so I can right-size the grade and test plan.

Share your media, temperature, pressure, and chloride level—I’ll propose the leanest viable grade1 and NDT2, then quote within 24 hours.

Practical checkpoints buyers should verify

- Note media (chloride ppm1), temperature, and cycle load to choose CF8 vs CF8M vs duplex.

- Call out solution anneal, passivation, and cleaning for sanitary/marine duty.

- Define pressure tests2 (e.g., hydrostatic 1.5× design) and leak criteria for housings.

Quality & packaging notes buyers care about

- Require ASTM A7811 common requirements; spell out weld-repair rules per A4882 if allowed.

- Include RT level and UT zones in the PO; avoid ambiguous acceptance.

- Use strapped, foam-lined crates with VCI and humidity cards; label heats and serials externally.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Alloy Choice | CF8 (≈304) | CF8M (≈316)1 | CF8M improves pitting resistance; slightly higher cost and passivation validation. |

| Corrosive Media | Austenitic | Duplex (CD4MCuN)2 | Duplex raises strength/corrosion margin; tighter heat-treat/NDT controls. |

| Standards | A781 + E446/E186 | Add A609 + E165 | Broader NDT increases confidence and timing; clarify acceptance.1 |

| Surface | Passivated (A967) | Electropolished | Better cleanability for food/pharma; extra cost/lead time.2 |

| Documentation | Basic COA | FAI/CMM + full trace | Reduces incoming inspection time; increases supplier workload. |

Conclusion

Specify process, ISO 8062-3 class, alloy/heat-treat, finish, and ASTM NDT up front—then upload your drawing for 24-hour DFM advice and a firm quote.

-

Exploring this resource will provide insights into how Broader NDT can enhance confidence and efficiency in inspections. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

This link will explain the advantages of electropolishing, crucial for maintaining hygiene standards in sensitive industries. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩