Deburring in Sheet Metal Fabrication: Techniques for Flawless Edges

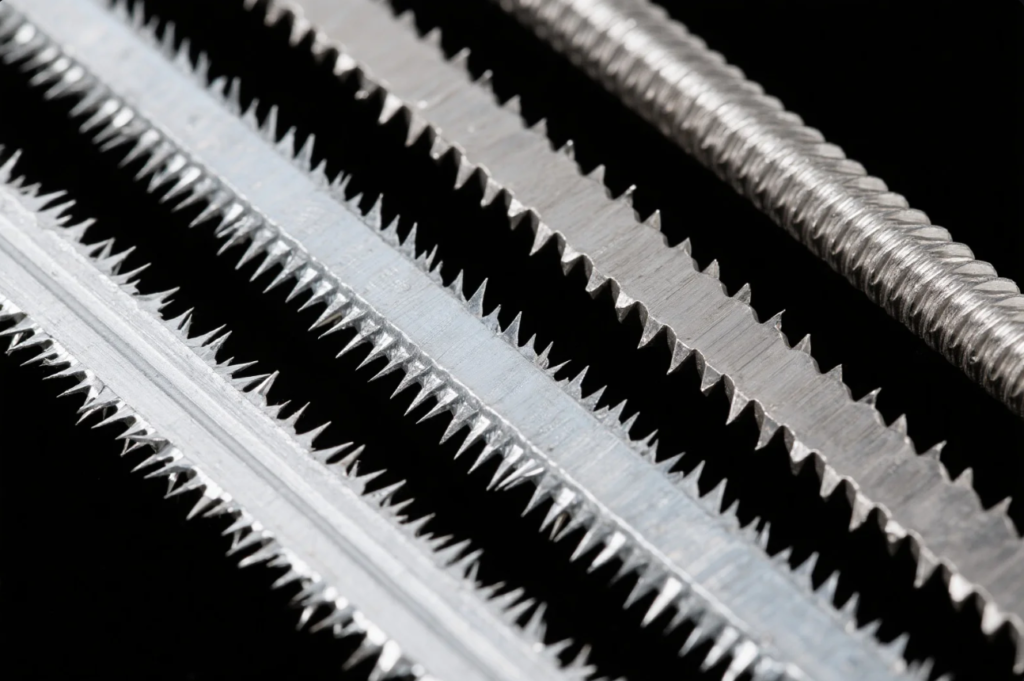

Burrs—the rough, sharp edges left behind after cutting or punching sheet metal—may seem like a minor problem. But in high-precision manufacturing, even the smallest edge defect can lead to assembly issues, increased wear, safety risks, and failed product inspections.

This guide explains what causes burrs, how to reduce them, and the most effective deburring methods used in automotive, aerospace, medical, and electronics manufacturing.

What Are Burrs in Sheet Metal Fabrication?

A burr is a raised edge or small metal protrusion that appears after punching, cutting, or shearing. Even if burrs are microscopic, they can cause:

- Misalignment during part assembly

- Safety hazards from sharp edges

- Electrical short circuits

- Paint or coating failures

What Causes Burrs in Sheet Metal Cutting and Punching

Key causes of burrs include:

- Dull cutting tools or dies

- Incorrect die clearance

- Vibration or poor alignment during punching

- Inconsistent cutting speed or pressure

📖 Learn more in the Journal of Materials Processing Technology

Burr Types: Primary vs. Secondary Burrs

There are two major types of burrs:

- Primary burrs – from cutting or punching

- Secondary burrs – from bending, welding, or machining processes

Proper inspection should catch both, especially for high-performance parts.

Differences in Burr Formation Across Steel, Aluminum, and Stainless

| Material | Burr Risk | Notes |

|---|---|---|

| Mild Steel | Moderate | Easily managed with sanding or tumbling |

| Aluminum 6061 | Low | Soft but prone to smearing |

| Stainless Steel | High | Tough to cut cleanly; needs advanced deburring |

How Tooling and Clearance Affect Burr Formation

Tool selection and clearance setup play a huge role.

| Material Thickness | Ideal Die Clearance |

|---|---|

| < 1mm | 6%–10% |

| 1–3mm | 10%–15% |

| > 3mm | 15%–20% |

Use carbide punches, sharpen frequently, and match tooling to material hardness.

Post-Processing Deburring Methods

There are five main categories of deburring processes:

1. Tumbling

Best for: small, high-volume parts

Process: Vibratory or rotary machines with abrasive media

Limitation: Not ideal for large or flat parts

2. Manual Sanding

Best for: large or custom components

Process: Belt sanding, disc grinding, flap wheel finishing

Limitation: Labor-intensive and inconsistent

3. Thermal Deburring

Best for: micro burrs in complex internal geometries

Process: Gas ignition in a sealed chamber

Limitation: High cost

4. Electropolishing

Best for: stainless steel, medical parts

Process: Electrochemical smoothing in acid bath

Limitation: Surface-dependent; not for all metals

5. Abrasive Flow Machining

Best for: hydraulic parts, manifolds, and fuel rails

Process: Pushing abrasive media through interior channels

Limitation: Complex and expensive

Case Study: Deburring Precision Medical Components

Client: EU-based surgical instrument manufacturer

Problem: Microscopic burrs on titanium cutting tools caused assembly line issues

Solution: Combination of tumbling + electropolishing + ISO 13485 validation

Result: 95% reduction in rework, passing Ra < 0.2µm surface finish standard

How to Choose the Right Deburring Process

| Process | Best For | Cost | Speed | Finish |

|---|---|---|---|---|

| Tumbling | Small metal components | Low | High | Medium |

| Sanding | Low-volume, flat parts | Medium | Slow | Medium–High |

| Electropolishing | Stainless/medical | High | Medium | High |

| AFM | Internal geometries | High | Medium | High |

| Thermal | Tight tolerances, small burrs | Very High | Fast | Very High |

💡 Tip: Use tumbling as a first pass, then apply precision finishing only where needed.

FAQs

Q1: Can burrs be completely eliminated?

A: No process is 100% burr-free, but combining sharp tooling and proper deburring ensures minimal residual burr.

Q2: Is manual deburring still relevant in modern production?

A: Yes, especially for prototypes, custom-shaped parts, or low-volume projects.

Q3: What’s the role of automation in deburring?

A: Robotic deburring arms and AI inspection cameras are widely used in automotive and aerospace factories.

Contact Us

Need smooth, safe, and burr-free sheet metal parts for your project?

📧 Email us at: [email protected]

🌐 Visit: https://primecustomparts.com

Prime is an ISO-certified, global sheet metal parts supplier with over 20 years of experience in deburring, bending, stamping, and finishing for industrial applications.