High‑Performance Engineering Plastics: Nylon, PPS, and PC in Modern Industries?

When industries push limits—higher heat, greater stress, chemical exposure—standard plastics like ABS fall short.

Engineering plastics such as PC, PA, PPS, and PAEK deliver superior strength, thermal stability, and chemical resistance. This guide compares major resins, explores EV and automotive applications, outlines best practices, and offers cost-performance advice.

Comparing ABS, PC, PA, PEEK, and other engineering plastics

Engineering plastics vary in performance. Here’s a helpful comparison:

| Material | Heat Deflection (°C) | Tensile Strength (MPa) | Chemical Resistance | Typical Applications |

|---|---|---|---|---|

| ABS | \~105 | \~40 | Moderate | Consumer housings, toys |

| PC (Polycarbonate) | \~130 | \~60 | Good | Lens covers, automotive lighting |

| PA (Nylon 6/6) | \~120 (unfilled) | 70–80 | Good (moisture sensitive) | Gears, mechanical parts |

| PPS (Polyphenylene Sulfide) | \~240 | \~60 | Excellent | Fuel system components, valve parts |

| PEEK (PEEK/PAEK family) | 250–260 | 90–100 | Excellent | Aerospace, medical implants |

- ABS is cost-effective and easy to mold—for basic consumer enclosures.

- PC offers high impact resistance and transparency—ideal for lighting and safety shields.

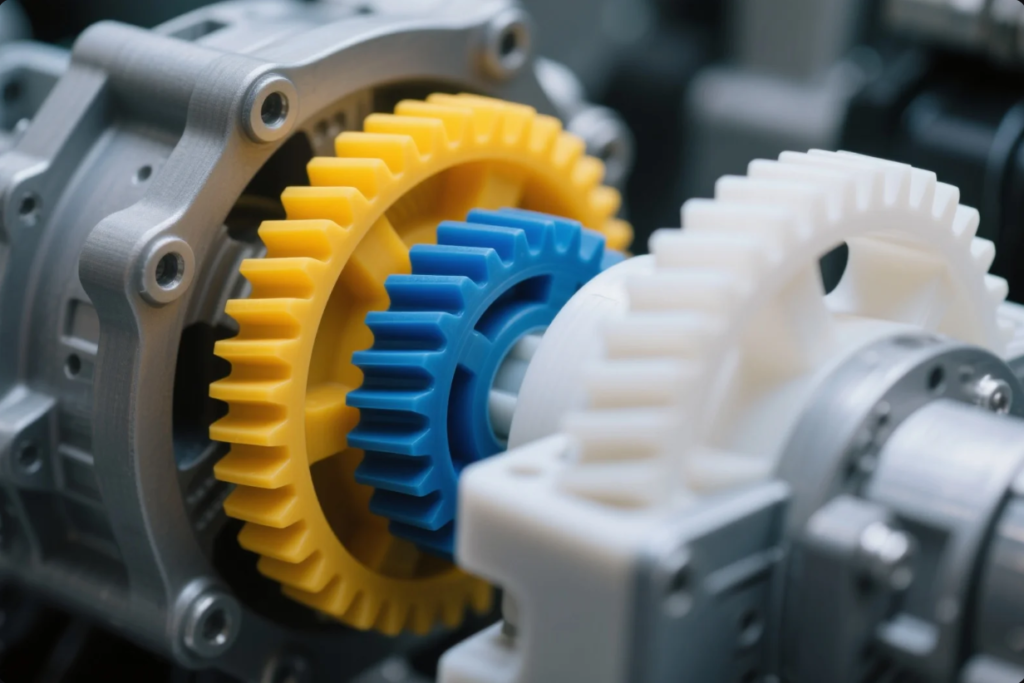

- PA (Nylon) is durable and abrasion-resistant—often used in gears and structural parts.

- PPS provides chemical and thermal endurance—great for EV under-hood applications.

- PEEK/PAEK excels in extreme conditions—used in aerospace, medical, and semiconductor parts.

More info: Polycarbonate – Wikipedia, PAEK – Wikipedia

Lightweight & high‑strength parts for EVs and automotive systems

EVs demand parts that are both light and durable.

Key parts and plastics:

- Battery housing insulators and busbars made from PPS for flame and chemical resistance.

- PC/ABS blends used for interiors—strong, aesthetic, and flame-resistant (UL 94 ratings).

- PA reinforced with glass used in under-hood brackets and connectors.

- Exterior trims and lens covers utilize PMMA or UV-stabilized PC.

Top suppliers: BASF automotive offers lightweight compounds. OEM requirements often include UL 94 V‑0 flame rating, VW PV 392, GM GM9697M.

Additional reading: Ultem (PEI) from SABIC

Best practices for PPS and PAEK in high-temperature or chemical environments

These high-end polymers need precise handling:

PPS Tips:

- Process between 320–360 °C; keep moisture <0.05%.

- Use corrosion-resistant steel (e.g., H13).

- Apply fast injection to enhance fiber alignment and precision.

PAEK/PEEK Tips:

- Mold at 360–400 °C.

- Use high-temp presses and hot runners.

- Anneal to relieve internal stresses and ensure dimensional stability.

- Employ additives like carbon fiber or PTFE for wear & friction resistance.

Resin sources include RTP Company PPS compounds and Victrex PEEK resins. Ideal for aerospace, chemical processing, and other extreme environments.

Read more: Materials Today article on PEEK

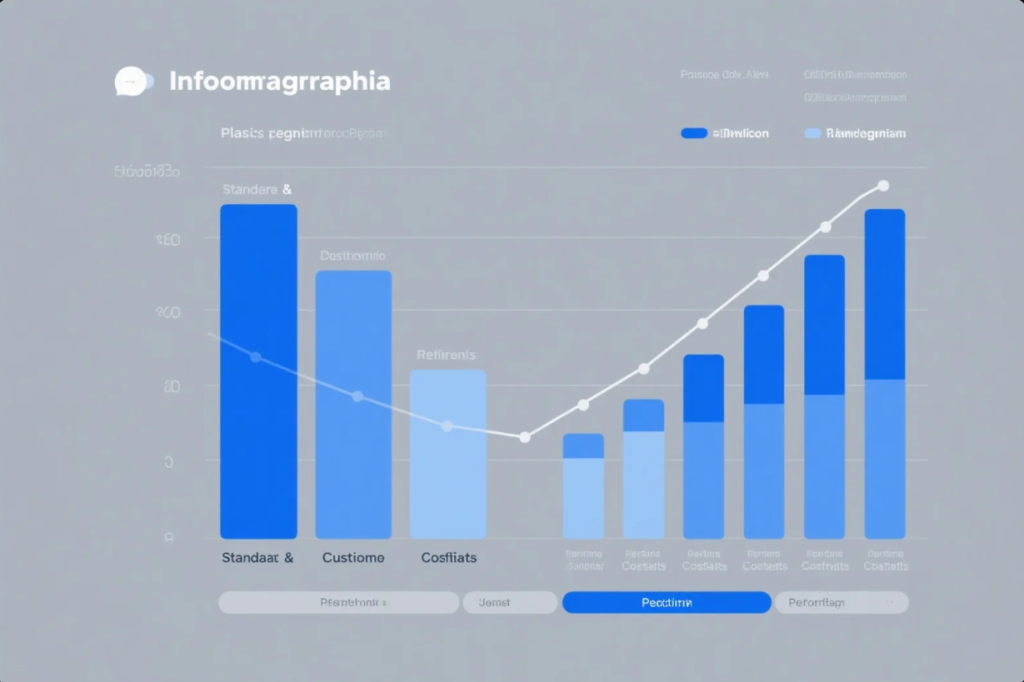

Cost-performance strategies: custom vs. standard resins

Understanding resin life cycle and sourcing impacts cost:

Standard Resins

- Off-the-shelf grades (PC, PA, PPS) offer reliable supply at \$3–6/kg.

- Minimal management and no special inventory.

Custom/Compound Resins

- Include additives like flame retardants, fillers, colorants for specific functionality.

- \$1–3/kg more expensive but optimize performance for application needs.

| Metric | Standard Resin | Custom Resin |

|---|---|---|

| Price per kg | Low–Medium | Medium–High |

| Performance | Standard | Tailored to demands |

| Supply Flexibility | High | Needs special ordering |

| Certification | Pre-certified | May need re-certification |

Prime offers both standard and custom resin solutions—backed by technical support and regulatory documentation.

FAQs

1. When is PEEK preferable to PPS?

Choose PEEK for >220 °C use or when FDA/USP approval is required—as seen in aerospace and medical implants.

2. What about moisture in glass-filled Nylon?

Nylon absorbs 2–3% moisture—cure appropriately to avoid dimensional instability and maintain strength.

3. Are custom resins worth it?

Yes—though cost increments, they reduce failure risks and align with unique performance needs.

4. Can PC be UV-resistant outdoors?

Yes—with UV stabilizers; grades meet ASTM G154 or ISO 4892 standards.

5. Do you make UL-rated EV parts?

Yes—Prime molds flame-resistant PC/ABS parts and provides UL Yellow Card documentation.

Contact Us

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Conclusion

Engineering plastics (PC, PA, PPS, PAEK) empower high-performance applications across EV, aerospace, and industrial sectors. By choosing the right resin, following proper molding procedures, and considering cost-performance trade-offs, you can optimize both product quality and profitability.

Partner with Prime for expert resin selection, precision molding, full technical guidance, and on-time global delivery.