How are defects in plastic parts prevented?

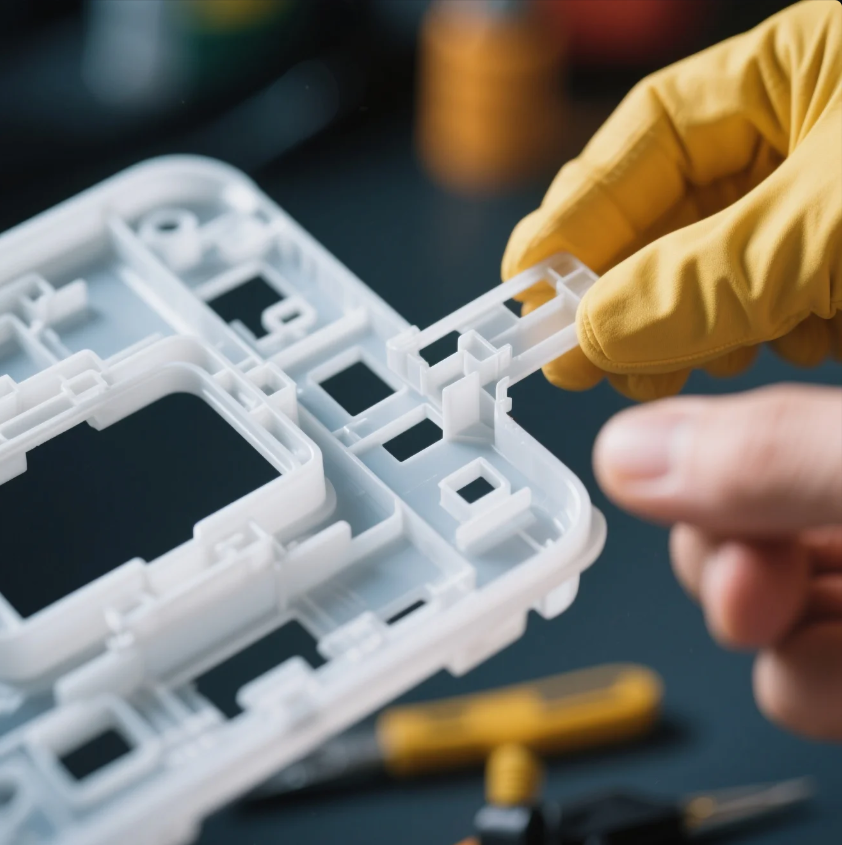

Many buyers face costly delays due to unexpected flaws in plastic parts.

Defects in plastic parts—like warpage, sink marks, or dimensional errors—can be avoided with smart design, skilled molding, and proper process control.

Knowing the root causes helps you prevent wasted time, money, and product failures.

Let’s break down the common issues and how we solve them at Prime.

What are the defects in plastic parts?

Many buyers don’t know what flaws to watch out for until after production.

Typical plastic part defects include warping, sink marks, flash, voids, short shots, and dimensional deviations.

These flaws often result from improper cooling, bad mold design, or inconsistent processing.

Common Plastic Defects and Causes

| Defect | Description | Main Cause |

|---|---|---|

| Warping | Part bends after cooling | Uneven shrinkage |

| Sink Marks | Surface dents in thick areas | Overpacked or poorly cooled |

| Flash | Thin excess at parting lines | Mold mismatch or high pressure |

| Short Shots | Incomplete part fill | Low injection pressure |

| Voids | Hollow pockets inside parts | Trapped air or cooling issue |

At Prime, we use mold flow analysis, tight process control, and quality audits to avoid these issues in every batch.

How to avoid warpage in plastic parts?

Warping frustrates clients when parts don’t align, snap, or fit correctly.

To prevent warping, ensure balanced wall thickness, proper cooling, material flow control, and uniform mold design.

Poor gate placement or uneven shrinkage often causes warpage.

Tips to Reduce Warpage

- Keep wall thickness consistent throughout the design

- Use materials with low shrinkage rates (e.g., PC, ABS)

- Optimize mold temperature and cooling layout

- Place gates near the thickest section

- Avoid sharp corners and sudden transitions

Prime engineers provide DFM reviews and mold optimization services to correct warpage issues before production starts.

How to avoid sink marks in plastic parts?

Sink marks ruin surface appearance and often appear on thick sections of molded parts.

To avoid sink marks, reduce wall thickness, use uniform geometry, and apply proper holding pressure during molding.

Gate and rib design also play a key role in material flow and cooling.

How Prime Prevents Sink Marks

| Action | Why It Helps |

|---|---|

| Use thinner, uniform walls | Reduces cooling imbalance |

| Place ribs with correct height | Avoids thick material zones |

| Apply holding pressure | Compensates shrinkage during cooling |

| Optimize mold temperature | Slows cooling to balance shrinkage |

At Prime, we offer free design consultations to help you eliminate sink risks early in the process.

What are the tolerances for plastic injection molded parts?

Tolerances affect how well parts fit, move, and assemble. Clients often ask what’s realistic for plastic.

Typical injection molded tolerances range from ±0.05 mm to ±0.2 mm, depending on material, mold design, and part size.

Critical dimensions can be held tighter with special tools or post-machining.

Tolerance Guidelines for Molded Plastics

| Dimension Type | General Tolerance | Notes |

|---|---|---|

| Small features | ±0.05–0.1 mm | Requires precision molds |

| Larger dimensions | ±0.1–0.2 mm | Normal production tooling |

| Hole locations | ±0.1 mm | May need secondary machining |

Prime uses CNC-machined molds, steel inserts, and automated QC to maintain tight tolerances, even across large orders.

Conclusion

Plastic part defects can be prevented with the right mold design, material choice, and process control. Small changes lead to major quality gains.

Need help fixing or preventing defects in your plastic parts? Contact Prime today for a free technical review and quotation. We deliver precision-molded, ISO-certified parts with guaranteed consistency and expert support.