How can I reduce costs in custom CNC parts?

Budgets feel tight. Deadlines move. I share proven CNC cost cuts today.

Custom CNC costs fall when I choose smart materials, clean designs, efficient processes, and tight logistics. I rely on standards and data, not guesswork.

I have led one-stop manufacturing programs since 1993. My team runs ten lines and sells wholesale only. So I pair speed with control and stable quality.

What truly drives cost in custom CNC parts?

Material prices keep rising. Complex designs add minutes fast. Packaging errors cause damage and returns. Lead times slip and hurt sales.

I attack four levers first. I optimize materials. I simplify geometry. I select the right machines. I stabilize logistics and documents. This framework works from prototypes to volume.

Material selection: which metals or plastics lower cost without risk?

Over-spec alloys inflate cycle time and scrap. I match loads, temperature, and environment first. Then I choose the lightest workable material with strong machinability.

I buy traceable lots under an ISO 9001 quality system and verify with trials. See the official ISO guidance: ISO 9001 quality management. For European shipments, I check substance rules early. See the RoHS directive overview from the European Commission: RoHS Directive. See the European Chemicals Agency page for REACH obligations: ECHA REACH legislation.

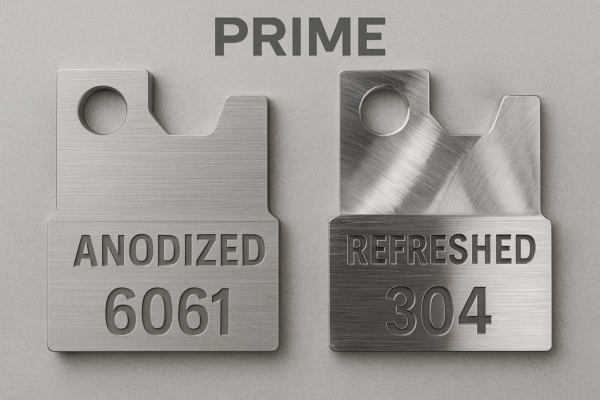

Key idea: choose 6061 for speed and weight when corrosion is moderate. Choose 304 only when chemicals or heat demand it. Log tool life and surface results for each trial.

Dive deeper: choose smart, not cheap (practical, tested rules)

I shortlist two materials per part and level the toolpaths. Then I record minutes, tool wear, and finish for each run. I include coating time, because finishes can flip the winner. For housings, 6061 with hard anodize often beats 304 on rate and life. For thread-rich fittings, C360 brass shears clean and protects taps. For wear faces, 7075 or case-hardened steel holds up best. For low-friction sliders, POM works well when heat stays moderate. I keep all certs with the lot and attach RoHS and REACH links in the traveler. I also set speeds and inserts using trusted data. Sandvik Coromant offers clear tactics by material family: Sandvik cutting guidance. These habits reduce risk and lock real savings before release.

Quick material rules

- Use 6061 for enclosures and brackets, then anodize.

- Choose 7075 near high loads and moving joints.

- Pick C360 brass for leak-tight, thread-dense manifolds.

- Select POM for low-friction guides and gears.

| Material | Machinability* | Density | Typical Win |

|---|---|---|---|

| 6061-T6 Aluminum | High | Low | Light housings and plates |

| 7075-T6 Aluminum | Medium | Low | High-load brackets |

| 304 Stainless Steel | Low | High | Harsh chemical exposure |

| C360 Brass | Very High | Medium | Precision threaded parts |

| POM (Delrin) | High | Low | Low-friction mechanisms |

*Relative guidance; always validate with trials in your cell.

Design for CNC machining: which geometry changes cut cycle time?

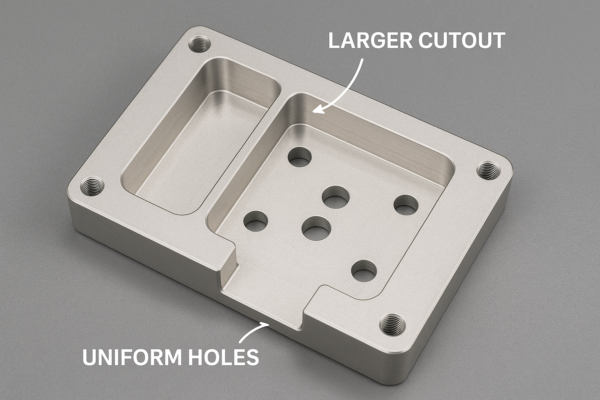

Sharp internal corners force fragile tools. Deep pockets deflect cutters. Complex features add setups and errors. I simplify where function allows.

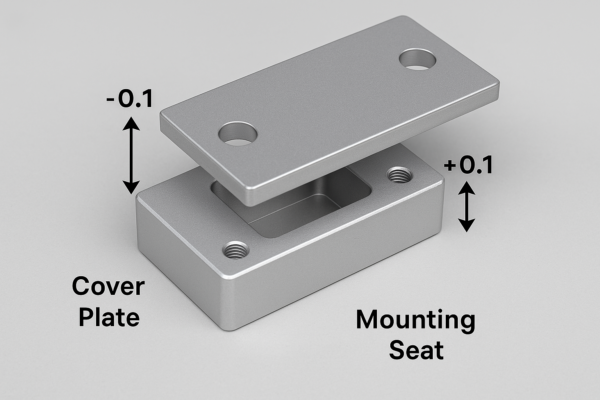

I enlarge internal radii, unify hole sizes, cap pocket depth, and set tolerances by function under ASME Y14.5. Clear drawings reduce disputes and rework. See the standard page: ASME Y14.5 Dimensioning and Tolerancing.

Featured advice: use the largest internal fillets the design allows. Prefer through threads when possible. Standardize hole diameters. Keep only critical tight bands.

Dive deeper: edit models for speed and stability (step-by-step)

I start DFM on day one and flag small inside corners that force tiny end mills. Larger fillets allow stronger tools and higher feeds. I unify holes into two or three diameters to cut tool changes and probe touches. I limit pocket depth to three times tool diameter when loads allow. That move reduces deflection and roughing passes. I replace undercuts with chamfers when sealing still works. I map GD\&T to function and avoid cosmetic tolerances. I hold ±0.02 mm on bearing seats, then relax covers to ±0.10 mm. Drawings stay readable under ASME Y14.5, so inspectors follow the same rules. For ductile alloys, I often use form taps with correct pilots and a light chamfer. Form taps displace material, so chips vanish and tool life improves. Harvey Performance explains the setup well: Form tap best practices. These edits trim minutes, raise yield, and prevent late deviations on the floor.

DFM checklist

- Increase internal radii to match strong tools.

- Unify holes to reduce tool swaps.

- Keep pocket depth reasonable.

- Prefer through threads when possible.

- Tighten tolerances only where function demands it.

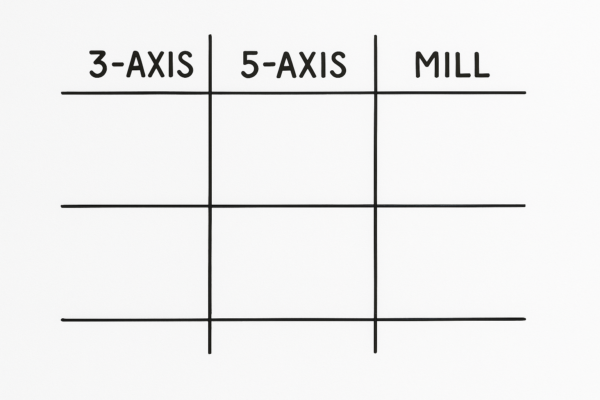

Process optimization: should I use 3-axis, 5-axis, or mill-turn?

Many teams default to 5-axis. Not every part needs it. I compare total minutes and setups, not just hourly rates.

Fast rule: 3-axis shines on plates and simple pockets. 5-axis wins on multi-face features. Mill-turn rules shafts and prismatic parts with turned ODs. Autodesk explains strategy and planning here: Autodesk 5-axis overview. Fusion help adds practical guidance: Fusion 360 machining help.

Dive deeper: balance setups, accuracy, and machine rates

I map features to faces and datums. Then I count setups, tool changes, and probe touches. A 5-axis center can collapse four operations into one. Fewer setups reduce stack-up error and often shorten CMM time. For plates and simple covers, a palletized 3-axis cell still wins with low fixture costs and fast tools. For shafts with milled flats and cross holes, I route to mill-turn. One chucking holds concentricity and reduces WIP. I document the route and freeze proven templates, so repeats start fast and run smooth. For planning and justification, I use NIST work on integrated process and operation plans: NIST decision methodology. This helps me compare alternatives with a consistent cost model.

| Process | Best For | Setups | Accuracy Risk | Cost Trend |

|---|---|---|---|---|

| 3-Axis Mill | Plates, simple pockets | 2–4 | Medium | Lowest on simple parts |

| 5-Axis Mill | Complex, multi-face parts | 1–2 | Low | Lowest when setups drop |

| Mill-Turn | Shafts, prismatic all-around | 1 | Low | Lowest on hybrids |

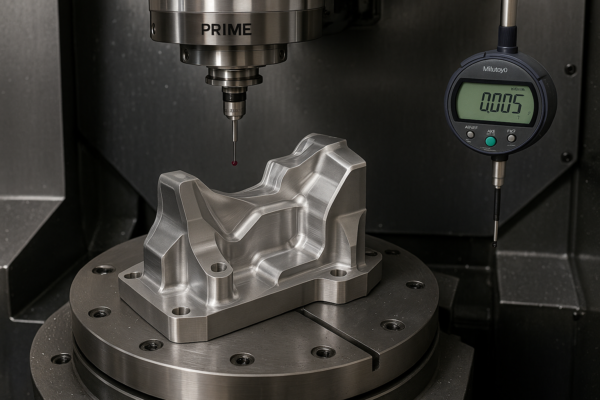

Quality and proof: how do I protect yield with minimal cost?

Quality failures ruin margins. Rework burns minutes. Returns damage trust. I focus checks where they matter and keep paperwork clean.

I use first-article reports, SPC on key features, and gage R\&R on new gauges. I hold evidence inside the QMS and share clear summaries at release. This approach supports audits without heavy overhead.

| Control | When I Use It | Why It Helps |

|---|---|---|

| First Article | New part or major change | Confirms setup and intent |

| SPC on seats | Tight fits and bearings | Detects drift early |

| Gage R\&R | New or shared gauges | Proves measurement trust |

Packaging, logistics, and Incoterms: how do I cut landed cost?

Freight shocks and damages drain margin. Late boxes hurt selling seasons. I build a steady plan that protects parts and time.

I use blanket purchase orders, scheduled releases, stackable cartons validated to ISTA, and clear Incoterms under ICC rules. See the International Safe Transit Association procedures: ISTA test procedures and the parcel profile: ISTA 3A overview. For trade terms, see the International Chamber of Commerce page: Incoterms 2020.

Working method: place a 6–12 month blanket order and release monthly. Right-size cartons for one-person lift and safe stacking. Test cartons to ISTA profiles. Align Incoterms at RFQ to clarify cost and risk splits. For EU compliance, confirm RoHS on EUR-Lex: Directive 2011/65/EU and keep REACH obligations clear on ECHA: REACH legislation.

Landed-cost playbook

- Blanket orders secure capacity and stable pricing.

- Carton design prevents damage and speeds handling.

- Ocean covers base load; air covers spikes without stockouts.

- Incoterms remove hand-off confusion and disputes.

- Documentation speeds customs and protects claims.

Energy and spindle time: where can I save more with low risk?

Energy costs rise every year. Non-cut time hides waste. I track both to unlock hidden savings.

I combine high-efficiency roughing, smart stepovers, and pallet-based loading. I reduce safe heights and dead moves. I monitor tool life by alloy, not just by part. I also review coolant mix and flow, because heat kills inserts. For broader ideas, I follow the U.S. Department of Energy’s AMMTO program: Advanced Materials and Manufacturing Technologies Office.

FAQs

Q1: How tight should I hold tolerances on CNC parts?

Hold tight only where function demands it. Place strict bands on bearing seats and seals. Follow the rules in ASME Y14.5.

Q2: When should I choose 6061 over 304 stainless?

Pick 6061 when speed and weight matter. Choose 304 when chemicals, salt, or heat are harsh. Validate with shop trials. For stainless tactics, see Sandvik Coromant guidance.

Q3: How do I avoid broken taps in production?

Prefer through holes. Use form taps in ductile alloys with correct pilots and a light chamfer. See Harvey Performance best practices.

Q4: Does 5-axis always save money?

No. It saves money when it collapses setups and improves positional accuracy. Run a short time study first. Reference Autodesk 5-axis overview.

Q5: Which packaging tests cut damage claims?

Use ISTA 3-Series drop and vibration profiles. Keep pass reports with your PPAP. For parcel freight, follow ISTA 3A. General procedures live here: ISTA procedures.

Q6: How do Incoterms change total landed cost?

Incoterms assign cost and risk at named points. Agree terms at RFQ to avoid disputes. See ICC Incoterms 2020.

Q7: What documents speed customs clearance?

Send certificates of analysis, heat lots, HS codes, and origin. Match the commercial invoice and packing list. Align RoHS claims with EUR-Lex RoHS text and REACH claims with ECHA REACH.

Q8: Can Prime combine CNC with stamping, welding, or casting?

Yes. I route mixed processes when they save more. You receive one plan, one schedule, and one invoice with steady quality.

Conclusion

Pick smart materials, simplify geometry, match processes, and plan supply. Then costs drop while quality and lead time stay stable.

Prime has delivered one-stop metal components since 1993. We run ten in-house lines for CNC parts, stamping parts, welding parts, casting parts, fasteners, and plastic parts. We operate with ISO-based systems and ship worldwide. Contact Prime today for a free DFM review, a firm quote, and a tailored cost-down plan. We respond fast, protect packaging, and keep quality stable. Let us be your custom CNC parts supplier, precision CNC parts machining partner, and ISO-certified casting parts manufacturer for long-term growth.