How Can You Get Metal Casting Parts Quick Quotation and Transform the Inquiry Operation Process?

Many buyers lose time and money due to slow responses1 and unclear supplier communication2.

Getting fast, accurate quotations for metal casting parts1 starts with detailed files, proper communication, and a proven supplier process. In this guide, you’ll learn how to prepare effective inquiries, understand cost drivers, master sample approval, and optimize RFQ (request for quote)2 conversion using site content.

After years of sourcing and project management, I know firsthand that having a clear, systematic inquiry process1 and the right partner like Prime2 makes all the difference.

Read on for step-by-step advice, actionable tips, and real-world examples—so you can get faster quotes1, avoid project delays, and turn more RFQs into real orders2.

Why Is Upfront Preparation With DFMEA and CAD Files Crucial for Fast Quotation?

Misunderstandings at the RFQ stage1 are the number one cause of project delays2.

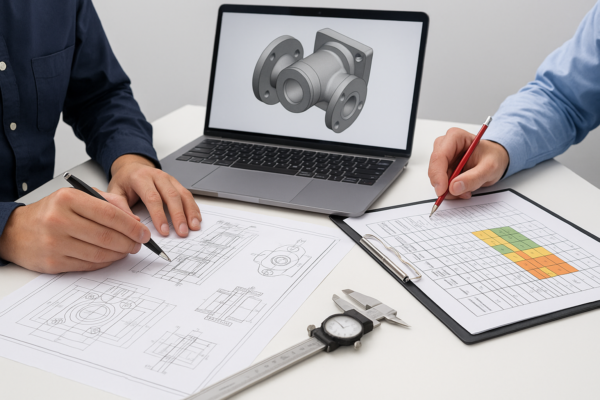

When buyers prepare with complete CAD drawings1 and run a basic DFMEA2 (Design Failure Mode and Effects Analysis), they make it easy for the supplier to quote fast and accurately. Clear requirements mean fewer emails, faster samples, and reduced risk of error.

In my experience, the best quotes come when the supplier receives:

- Complete 2D/3D CAD files (.STEP, .IGS, .DWG, .PDF)1

- Material and surface finish specifications2

- Tolerance and technical requirement notes

- Estimated order quantity and usage environment

- Special packing or labeling needs

Whenever I’ve provided vague or incomplete info, my quotes got delayed or came back with errors. When I give detailed, organized files1 up front, I often get a full quote and suggestions for design improvement2 in under 24 hours.

Why Early DFMEA and CAD Files Matter

| Preparation Step | What It Includes | Direct Benefit |

|---|---|---|

| CAD file submission1 | 2D/3D design, all views | Eliminates guessing |

| Material list | Alloy grade, standard | Ensures right pricing |

| DFMEA summary2 | Risk points, critical dimensions | Prevents errors, redesign |

| Batch quantity info | Annual/quarterly/monthly | Affects mold and unit price |

| Packing requirements | Export crates, eco packing, labeling | Reduces shipment damage |

Actionable Tip

Always send a short email summary1 with your files, highlighting any special features or risks. Prime’s engineers routinely reply with process advice2 that saves time and money at mass production.

What Are the Main Factors Affecting Metal Casting Quotation Costs?

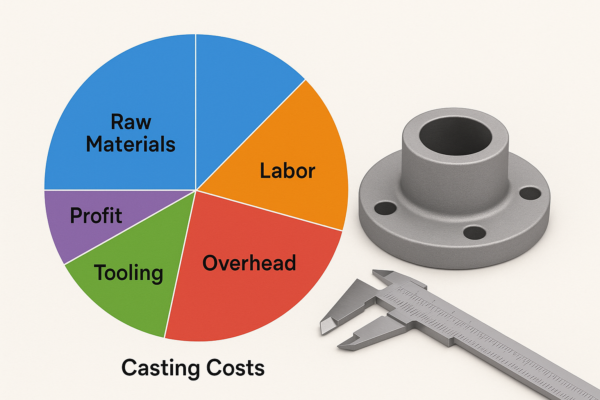

Getting five different quotes for the “same” part? It’s usually because critical cost factors1 were unclear or not standardized2.

A reliable, transparent supplier like Prime will ask for or clarify the following:

- Material grade and certifications (e.g., aluminum A380, stainless 304, etc.)1

- Part weight, size, and wall thickness (affects material use and casting process)

- Annual or batch volume (affects mold amortization and pricing)

- Required process (die, sand, precision/investment casting)

- Tolerance and surface finish needs (tight tolerance or mirror finish adds cost)2

- Tooling/mold cost and life

- Packing and shipping method

Every line item counts. For example, a die-cast aluminum bracket1 for the auto industry may cost more upfront for the mold, but if the batch is large, the unit price drops sharply2.

Common Cost Factors in Metal Casting RFQs

| Cost Factor | How It Impacts Price | Details Required from Buyer |

|---|---|---|

| Material type1 | Main cost driver | Alloy, standard, certificate |

| Part complexity | Affects mold/tooling cost | 3D files, feature list |

| Size & weight | Influences raw material | Part drawings, weight/unit |

| Tolerance/finish2 | Precision increases cost | GD\&T, surface roughness, coating |

| Mold/tooling | High for die, low for sand | Mold type, reusability |

| Quantity | Lowers unit price | Order batch or forecast |

| Packing & logistics | Adds to total landed cost | Special needs, shipping address |

Actionable Tip

Ask your supplier for a full breakdown and justification for each cost1. Prime always provides a detailed quote sheet that includes all options, so there are no hidden fees.

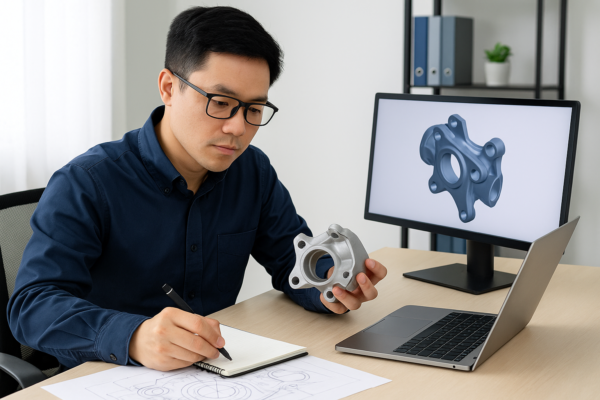

How Does Prime Manage the Sample Confirmation and Mass Production Flow?

A fast quote is meaningless without a robust sampling and production approval process1.

Prime’s sample-to-mass production flow2 ensures you never get “surprised” by out-of-spec parts. It includes:

- Technical review of your drawings and DFMEA by engineers

- Rapid prototyping (3D print or soft tool) within 3–7 days1

- Full inspection and sample report with photos and measurement data

- Your feedback and written approval (including packing & labeling)

- Pilot production run with optional pre-shipment inspection

- Mass production with in-process and final QC checks2

- Export packaging and logistics with full documentation and tracking

I’ve personally worked with many factories. Prime’s process is the only one where I get digital reports1, packing photos, and real-time status updates2 at every stage.

Prime Factory Sample-to-Production Workflow

| Step | Key Action | Customer Role |

|---|---|---|

| Drawing Review | DFM/DFMEA, material confirmation1 | Approve/revise as needed |

| Sample Making | Prototype via 3D print or soft tool2 | Review physical samples |

| Sample QC | Measurement, surface, strength test | Approve or request changes |

| Packing Review | Custom label/pack photo/video | Confirm export compliance |

| Pilot Batch | Small run for line validation | Optional witness/inspection |

| Full Production | Scaled run, regular QC | Receive schedule updates |

| Shipment | Export paperwork, insurance | Approve shipping documents |

Actionable Tip

Always ask for detailed sample and packing photos1. Prime always sends these for my sign-off before mass production2—no unpleasant surprises at delivery.

How Can You Guide RFQs Through Website Content and Maximize Conversion?

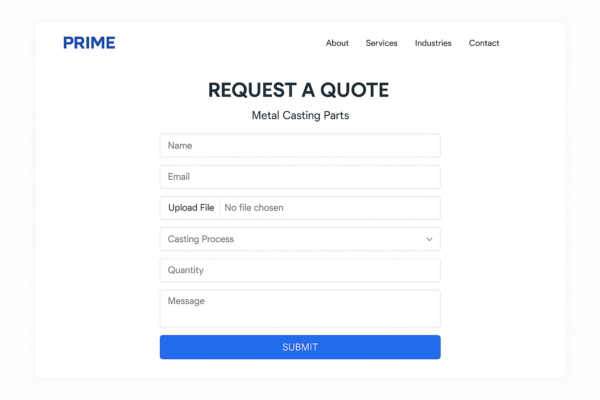

A buyer-friendly website1 is crucial for converting visitors into real RFQs. Many suppliers lose business due to vague forms2 and slow replies.

The best supplier sites—like Prime’s official website—include:

- RFQ forms with mandatory CAD/drawing upload1 and all critical fields (material, quantity, surface, deadline)

- Step-by-step explanation of inquiry, quotation, sample, and order processes2

- Real sample photos, videos, and case studies for trust-building

- Live chat or email support ([email protected]) with response time promises

- Display of ISO certificates, process videos, and customer testimonials

I always fill out every required field and attach drawings in my first message. Prime’s site1 confirms receipt immediately and I often get my quote in less than 24 hours2.

Website Content That Drives RFQ Conversion

| Conversion Feature | Description | Buyer Benefit |

|---|---|---|

| Full RFQ form | All key specs, file upload, deadline, comments | No missing info, faster reply |

| Process explanation | Step-by-step with visuals | Transparent expectations |

| Real sample/case photos1 | Visual proof of ability and experience | Trust, peace of mind |

| Fast response promise2 | 24h quote, clear support channels | Confidence, no wasted time |

| Certificates/reports | ISO, test reports, awards on display | Assurance of quality |

Actionable Tip

Bookmark your supplier’s RFQ page1. Submit a complete, detailed inquiry2 on your first try and follow up by email if you have questions—this always gets you to the front of the queue.

Real Project Case: How Prime Streamlined an Automotive Casting Inquiry

A European automotive OEM needed 50,000 high-precision aluminum brackets1 on a tight timeline. They shared full CAD drawings, specs, and a DFMEA checklist2 through Prime’s online RFQ form.

Prime’s engineers replied with DFM suggestions and a quotation breakdown within 16 hours. Prototypes were made in 7 days, with full test and packing reports. The customer confirmed by photo, and mass production1 began with daily status updates. The project delivered on time, zero defects2, with full traceability—boosting the buyer’s trust and their own sales.

Packaging, Delivery, and Global Support: Prime’s Edge

Proper export packaging1 and logistics support2 are essential to protect your order and meet deadlines.

Prime uses custom cartons, foam, export crates, and barcode or QR labeling1 by customer requirement. Every order is photographed and documented before shipment. Prime’s team provides DDP, FOB, CIF, and door-to-door shipping2, with tracking, customs support, and insurance.

My last shipment to North America was tracked every step, arrived without damage, and cleared customs faster1 thanks to clear labeling2 and paperwork provided by Prime.

Frequently Asked Questions (FAQs)

1. How soon can I get a quote?

Prime responds within 24 hours if you provide full CAD files1 and specs. Urgent RFQs often get replies even faster.

2. Can Prime help if I only have a sample, not a drawing?

Yes. Prime offers reverse engineering2 and can create CAD files1 from your sample.

3. Does Prime provide DFM and technical advice1 for free?

Absolutely. Prime’s engineers review every project and suggest optimizations at no extra cost.

4. What’s the usual sample lead time2?

Most prototypes and samples are ready in 5–10 days after drawing approval.

5. Can Prime handle complex or urgent projects?

With 10 lines and an experienced team, Prime delivers urgent and complex projects1 with speed and quality.

6. Which payment and shipping methods2 are supported?

T/T, L/C, PayPal for payment. Shipping via DDP, FOB, CIF, air, or sea to over 80 countries.

7. What happens if there’s a quality issue?

Prime has a clear claim process—just contact [email protected] within 7 days. Problems are solved with free rework or refund as needed.

8. How do I start an inquiry?

Go to https://primecustomparts.com/ or email [email protected] with your requirements and files.

Conclusion

Prime combines rapid quotation, technical excellence, and end-to-end support—transforming your RFQ into reliable, on-time deliveries. For your next metal casting1 project, trust Prime for speed, quality, and worry-free global service.

Visit https://primecustomparts.com/ or email [email protected] to get a free, fast, and accurate quote today.

-

Explore this link to gain insights into metal casting techniques that ensure quality and efficiency in your projects. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

This resource provides insights into various payment and shipping methods, crucial for global transactions. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩