How Custom Metal Forgings Improve Strength & Precision in Aerospace & Automotive Parts?

Faulty metal components often result in operational failures1, costly downtime, and compromised safety. Custom metal forgings effectively eliminate these risks by delivering enhanced strength, precision, and reliability.

Custom metal forgings significantly enhance strength, durability, and precision, making them ideal for aerospace and automotive industries. Prime International offers ISO-certified custom forging services1, ensuring high-quality components with reduced production costs and minimal rework.

Explore below how customized forgings1 can revolutionize component reliability2 in your critical applications.

What Is Die Forging & Why Choose It for High-Strength Automotive Components?

Weak or inconsistent automotive components1 can cause safety hazards and frequent recalls. Die forging2 resolves these problems by consistently producing parts that withstand heavy loads and stress.

Die forging is a process where metal is heated and shaped under high pressure within a mold (die). This method creates automotive parts1 with superior strength, precision, and fatigue resistance, essential for critical applications.

Benefits of Die Forging for Automotive Components:

| Advantage | Benefit |

|---|---|

| Enhanced Durability1 | Reduces the risk of part failure |

| Superior Strength2 | Ensures safety under extreme stress |

| Precise Dimensions | Minimizes additional machining |

| Better Grain Structure | Improves overall component life |

From experience, die-forged components1 offer unparalleled reliability. Partnering with ISO-certified suppliers2 like Prime guarantees consistently high-quality parts tailored for demanding automotive applications.

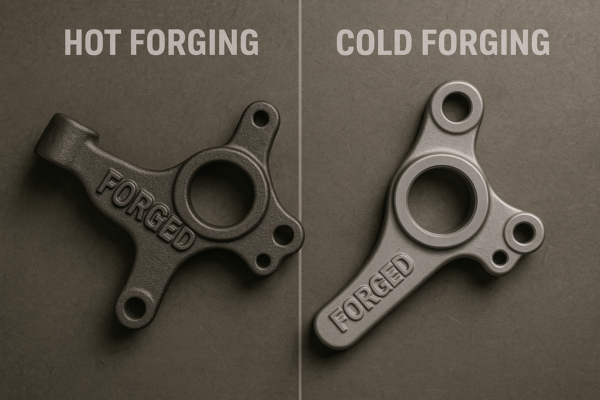

Hot Forging vs Cold Forging: Which Method Delivers Better Aerospace Parts?

Incorrect forging methods lead to aerospace component failures1, affecting safety and increasing operational costs. Choosing between hot and cold forging correctly ensures optimal part performance.

Hot forging1 involves heating metals above recrystallization temperatures, providing greater ductility and formability. Cold forging2 is performed below these temperatures, ensuring precision dimensions and superior surface finish. Selecting the right method depends on specific aerospace requirements.

Comparison of Forging Methods:

| Criteria | Hot Forging | Cold Forging |

|---|---|---|

| Strength & Toughness | Higher toughness | Higher tensile strength1 |

| Dimensional Accuracy | Moderate, requires finishing | High accuracy, minimal finishing2 |

| Surface Quality | Moderate | Excellent, smooth finish |

| Cost | Higher tooling costs | Lower overall cost |

My clients in aerospace have experienced superior results by matching the correct forging method1 to their specific component requirements. Prime provides expert advice, ensuring each forging method1 meets exacting aerospace standards2.

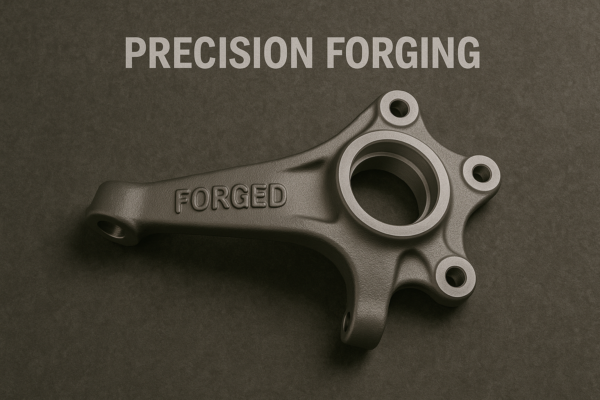

Understanding Precision Forging: How Tighter Tolerances Reduce Cost & Rework?

High rework rates and material waste significantly inflate production costs1. Precision forging2 tackles these issues by closely matching final component dimensions from the outset.

Precision forging1 produces components close to their finished dimensions, reducing the need for extensive machining. Tighter tolerances enhance part performance, significantly cutting costs and improving production efficiency.

Advantages of Precision Forging:

- Material Efficiency1: Less waste and reduced material usage

- Cost Savings2: Lower machining and finishing expenses

- High Quality: Consistently precise dimensions

- Improved Production Efficiency: Shorter production cycles

From personal experience, precision forgings1 have notably reduced client costs and boosted production speed. Prime’s precision forging processes consistently meet tight tolerance specifications2, offering significant long-term savings.

From Machinery to Energy: Applications of Custom Forged Parts in Heavy Industry

Inferior metal parts often cause machinery breakdowns1, costly maintenance, and production delays. Custom forged parts2 offer robust solutions that withstand harsh industrial conditions.

Custom forged components significantly enhance reliability and longevity1 across heavy industries, including machinery manufacturing and energy production. They are designed to withstand extreme operating conditions, reducing downtime and repair costs.

Industrial Applications & Benefits:

| Industry | Forged Components | Key Benefits |

|---|---|---|

| Machinery | Gears, shafts, couplings | Increased durability1 |

| Energy | Turbine blades, valves, flanges | Enhanced heat resistance2 |

| Mining | Crusher parts, drill components | Superior wear resistance |

Clients consistently find custom forged components1 outperform standard parts. Prime’s advanced forging techniques2 provide unmatched durability, meeting heavy industry’s rigorous demands.

Frequently Asked Questions (FAQs)

Q1: What types of metals can be forged by Prime?

Prime can forge metals including steel, stainless steel1, aluminum, copper, and titanium2.

Q2: How does custom forging enhance part quality?

Custom forging1 aligns the metal’s grain structure, significantly improving strength, fatigue resistance2, and durability.

Q3: What certifications does Prime hold?

Prime holds ISO 9001 certification1, guaranteeing superior quality control standards2.

Q4: Can Prime provide samples before mass production?

Yes, Prime offers sample prototypes1 to ensure all specifications meet customer expectations before mass production2.

Q5: What is Prime’s typical lead time for custom forgings?

Prime typically delivers custom forged components1 within 3 to 6 weeks, depending on complexity and order volume2.

Conclusion

Custom metal forgings1 from Prime International significantly boost strength, precision, and reliability for aerospace, automotive, and heavy industry applications2.

Ready to strengthen your components? Contact Prime International today for free consultations1, quick quotations, and customized solutions. Experience rapid delivery2, exceptional quality, and reliable customer service.

Contact Information:

Website: https://primecustomparts.com/

Email: [email protected]

-

Exploring this link will provide insights into how free consultations can enhance customer relationships and drive sales. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

This resource will help you understand the importance of rapid delivery in improving customer satisfaction and loyalty. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩