How Custom Plastic Parts Improve Product Performance Across Industries?

Struggling with metal parts that add weight or corrode?

Custom plastic components improve performance by reducing weight, resisting corrosion, and cutting costs. These parts are critical in automotive, electronics, and medical devices.

Don’t settle for average. Keep reading to discover how we ensure precision, durability, and custom-fit plastic solutions.

What Are Custom Plastic Components and Why They Matter in Manufacturing?

Many manufacturers still use standard metal parts—even when they don’t fit their product design.

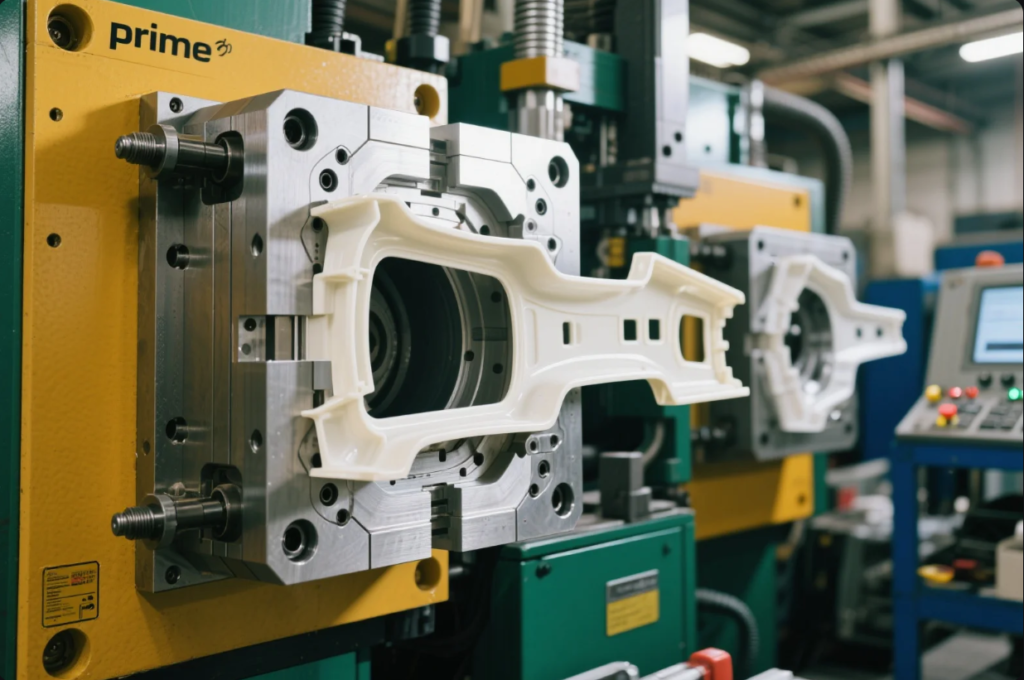

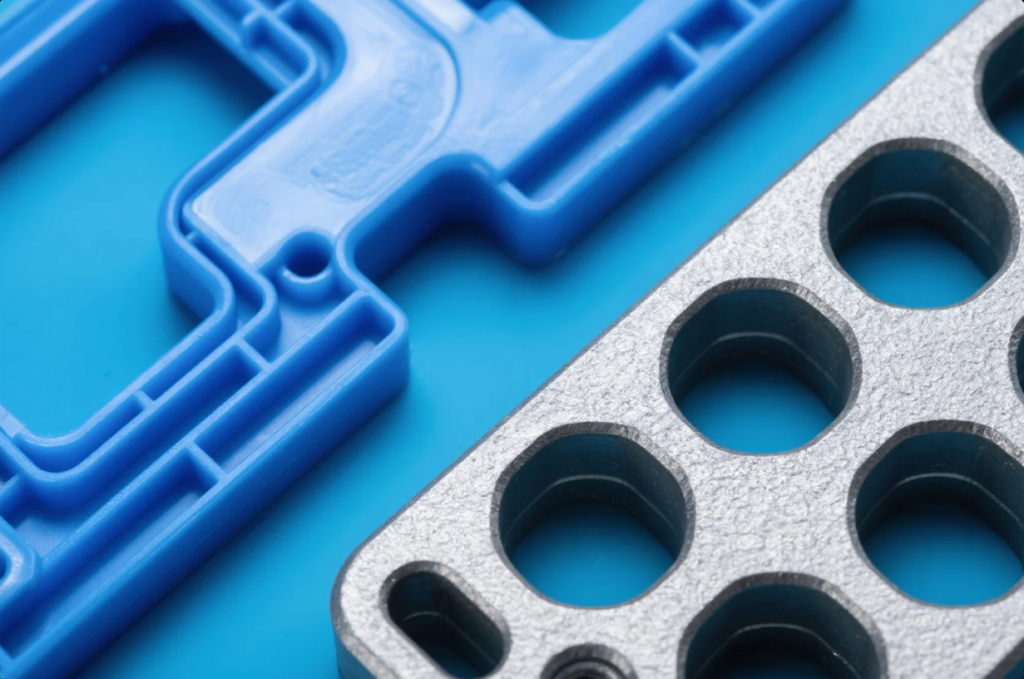

Custom plastic components are non-standard parts made to specific client drawings, materials, and performance needs. They are produced through injection molding, CNC machining, or 3D printing. Unlike off-the-shelf options, these parts solve unique product challenges.

- Injection molding: a process for shaping molten thermoplastics like ABS or PEEK

- CNC machining: a method for precision subtractive manufacturing with computer control

| Process | Application Examples | Tolerance | Tooling Cost |

|---|---|---|---|

| CNC Machining | Prototypes, low-volume parts | ±0.01 mm | None |

| Injection Molding | Mass production of housings, clips | ±0.05 mm | Medium |

| Extrusion/Forming | Tubes, seals, frames | ±0.1 mm | Low |

Example: An automotive client needed high-heat clips not available off‑the‑shelf. We delivered customized ABS clips within 10 days—saving them 18% in rework cost.

Common Applications: Automotive, Electronics, Medical, and Aerospace

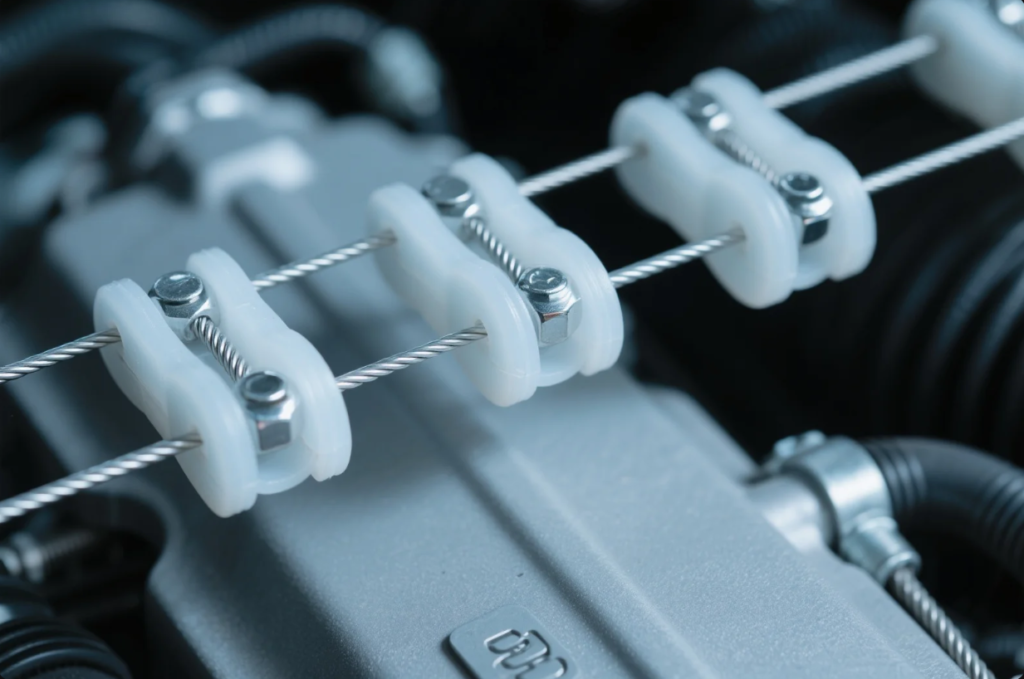

Automotive

- Wire harness clips

- Under‑hood connectors

- Lightweight covers

Plastic like PA66 and PBT GF30 resists grease, heat, and vibration.

Electronics

- Switch housings

- PCB enclosures

- EMI shielding

We use UL-certified flame-retardant materials such as PC+GF and FR‑ABS.

Medical

- Catheter hubs

- Diagnostic device shells

- Surgical handles

We follow ISO 10993 for biocompatibility in PP, PC, and POM.

Aerospace

- Wire clamps

- Brackets

- Duct fittings

Materials like PEEK reduce weight while handling flight stress.

| Industry | Common Parts | Material Traits | Prime Value |

|---|---|---|---|

| Automotive | Clips, covers | Heat resistant, light | Fast prototyping |

| Electronics | Housings, supports | Flame retardant | UL-rated materials |

| Medical | Shells, tools | Biocompatible | ISO cleanroom production |

| Aerospace | Ducts, panels | Flame proof, stiff | PEI/PEEK machining |

Benefits Over Metal Parts: Weight Reduction, Corrosion Resistance, and Cost

Plastic components outpace metal in many areas of design and production.

| Feature | Plastic | Metal |

|---|---|---|

| Weight | Lightweight | Heavy |

| Corrosion Resistance | Excellent | Needs coating |

| Insulation | Built-in electrical barrier | Conductive |

| Complex Design | Molded with ease | Requires machining |

| Cost (High Volume) | Low per-unit price | Higher material + processing |

Source: EngineeringChoice.com

Use Case:

A telecom brand switched from aluminum to ASA+PC plastic for housing. It reduced weight by 70% and passed UV + water ingress tests (IP67).

How PrimeCustomParts.com Delivers Precision and Durability in Plastic Parts

We deliver quality through ISO-certified production, advanced tooling, and deep experience.

Why Choose Prime?

- 10 in-house production lines

- ISO 9001:2015 certified

- ±0.01 mm precision with full inspection

- Cleanroom molding for medical parts

- Export-grade packaging with labels and barcodes

- Flexible low- or high-volume orders

| Step | Description | Lead Time |

|---|---|---|

| DFM + Quotation | Engineering review & free quote | 1–2 working days |

| Prototyping | CNC or molding samples | 5–7 working days |

| Mass Production | Certified production + QC | 10–15 days |

| Packing | Moisture proof + barcode | 1–2 days |

| Shipping | DHL, FedEx, or ocean freight | 3–25 days |

We provide full traceability from order to delivery, helping global customers stay on schedule.

FAQs About Custom Plastic Parts

What materials do you offer?

ABS, PC, Nylon, PTFE, PEEK, PP, and more.

What tolerances can you meet?

±0.01 mm (CNC); ±0.05 mm (molded parts).

Do you support small orders?

Yes, we support prototyping and small runs.

Are your materials certified?

Yes. ISO 9001 certified. RoHS, REACH, FDA available.

How can I get a quote?

Email [email protected] or visit https://primecustomparts.com

Get in Touch with Prime

Looking for a reliable custom plastic part supplier?

Prime delivers ISO-certified precision, quick quotes, and fast shipping.

Our team reviews your drawings and offers optimized solutions with real results.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Conclusion

Custom plastic parts enhance performance, reduce cost, and unlock flexible design in every industry.