How do you cut sheet metal smooth?

Cutting sheet metal often leaves jagged edges that are unsafe and hard to finish.

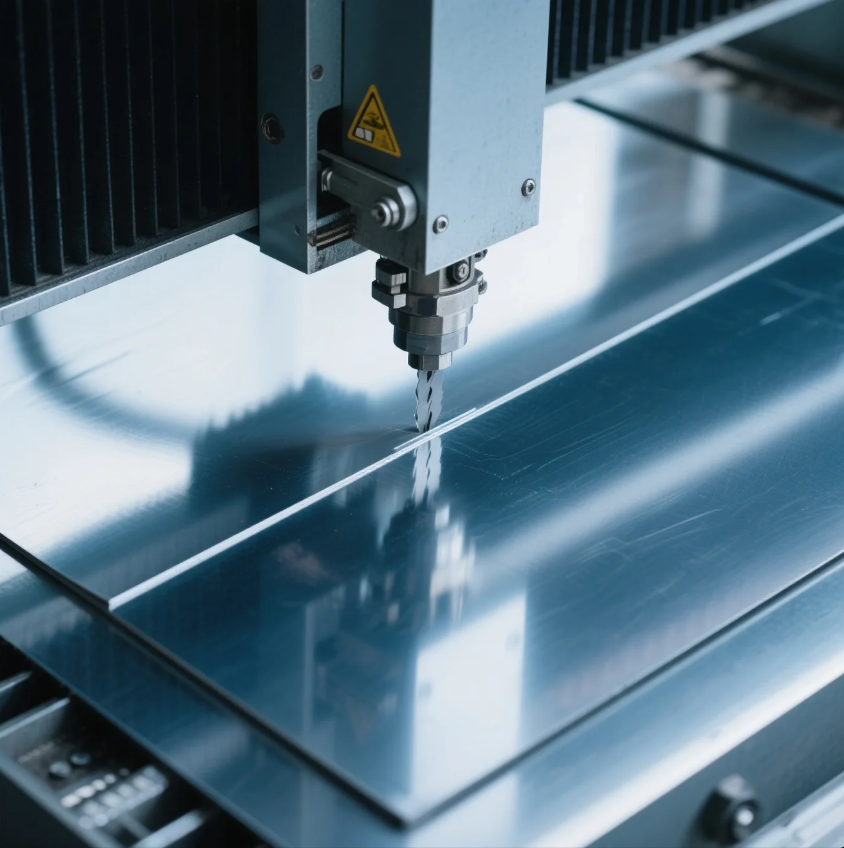

To cut sheet metal smoothly, use sharp tools like aviation snips, jigsaws with metal blades, or laser cutters. Follow up with edge finishing tools for a clean result.

At Prime, we use CNC and laser machines for precision cuts, followed by smoothing processes to deliver safe, professional-quality edges every time.

What is the best tool for smoothing edges on a piece of metal?

A sharp cut still leaves sharp edges—smoothing is a must.

The best tool for smoothing edges is a flap disc, belt grinder, or handheld deburring tool, depending on part size and complexity.

At Prime, we apply these tools across aluminum, steel, and stainless parts to create safe, burr-free components ready for coating or assembly.

Top Smoothing Tools

| Tool | Ideal For |

|---|---|

| Flap Disc | Long, exposed edges |

| Belt Grinder | Straight, thick sheet edges |

| Deburring Blade | Holes, curves, internal corners |

| Rotary Tool | Tight areas or detailed parts |

We match the tool to your part’s geometry and material to ensure efficient, safe finishing.

How do you smooth metal by hand?

Manual work still matters—especially for small batches or rework.

To smooth metal by hand, use a flat file, sandpaper, or emery cloth. Begin with coarse grit and move to finer grades for a clean finish.

At Prime, we hand-smooth edges on low-volume CNC parts and customized prototypes, ensuring every unit meets export-ready standards.

Step-by-Step Manual Smoothing

- Secure the metal part with a clamp.

- File the edge using a mill file at 45°.

- Switch to 180–400 grit sandpaper.

- Clean off debris with a dry cloth.

- Inspect with gloves to ensure no burrs remain.

This method is ideal for DIY, low-run, or sensitive areas of formed sheet parts.

How do you cut metal smoothly?

A clean cut reduces post-processing—and saves time.

To cut metal smoothly, use a sharp blade, steady feed rate, and the right tool for the material. Snips, jigsaws, and shears all work—with proper technique.

At Prime, we use laser cutting or CNC shearing to achieve perfectly smooth edges without secondary operations.

Smooth-Cut Metal Tips

| Tool | Cutting Best Practices |

|---|---|

| Aviation Snips | Use short, clean cuts, not long tears |

| Jigsaw | Use bi-metal blades + cutting fluid |

| Nibbler | Great for curves, minimal distortion |

| Laser Cutter | Highest precision, zero burrs |

Avoid dull blades—rough cuts often come from poor maintenance, not the wrong tool.

What is the best way to cut sheet metal cleanly?

Clean cuts aren’t just about tools—they’re about method.

The best way to cut sheet metal cleanly is using a laser cutter or CNC shear. For manual work, sharp aviation snips or a jigsaw with fine-tooth blades work well.

At Prime, we choose cutting methods based on part volume, material, and edge requirement. We deliver parts that require little to no rework.

Clean Cutting Solutions

| Application | Best Method |

|---|---|

| High precision | Fiber laser cutter |

| Straight lines | Guillotine shear |

| Home/diy projects | Snips or fine-tooth jigsaw blades |

| Complex cutouts | CNC punch or rotary tool |

Need ultra-clean edges for assembly, coating, or safety? We have the tools and techniques ready.

Conclusion

To cut sheet metal smooth, use sharp tools, steady pressure, and always finish with edge smoothing.

Need clean-cut metal parts with ready-to-use edges? Prime delivers CNC cutting, edge deburring, and ISO-quality sheet metal parts—made for safe handling and perfect fit. Contact us now for a production-ready quote.