How do you dull the edge of sheet metal?

Sharp edges on sheet metal aren’t just unsafe—they can ruin your entire assembly.

To dull the edge of sheet metal, use sanding, filing, edge rounding, or hemming to soften sharp cuts and create smooth, safe profiles.

At Prime, we apply this finishing step on all cut, punched, or bent sheet metal components, especially for parts used in enclosures, electronics, and handling-intensive applications.

How do you make metal look dull?

High-gloss metal isn’t always ideal—sometimes, low shine looks better and hides fingerprints.

Use abrasive pads, Scotch-Brite wheels, or chemical etching to give metal a matte or dull appearance.

At Prime, we offer dull finishes like brushed aluminum, bead-blasted stainless steel, or matte powder coating for both cosmetic and anti-glare needs.

Common Dull Finishing Methods

| Method | Effect |

|---|---|

| Scotch-Brite Pad | Soft matte finish, light scratches |

| Bead Blasting | Uniform dull texture |

| Chemical Etching | Low-sheen, chemically softened look |

| Sandpaper (320+ grit) | Directional satin or dull polish |

These finishes also improve paint adhesion and hide wear from frequent use.

How do you dull a sharp edge?

Even if your part is accurate, a sharp edge can still cut skin or scratch surfaces.

Dull a sharp edge with a file, sandpaper, or a deburring tool—removing just enough material to round off the corner.

At Prime, we hand-finish or machine-round edges on sheet metal brackets, panels, and frames, especially where human contact is frequent.

Tools to Dull Edges

| Tool | Best For |

|---|---|

| Flat File | External straight edges |

| Rotary Deburr Tool | Inside holes or slots |

| Sandpaper Block | Final smoothing pass |

| Edge Rounding Bit | Uniform radius along long edges |

A smooth, dull edge protects workers and improves part durability in assembly.

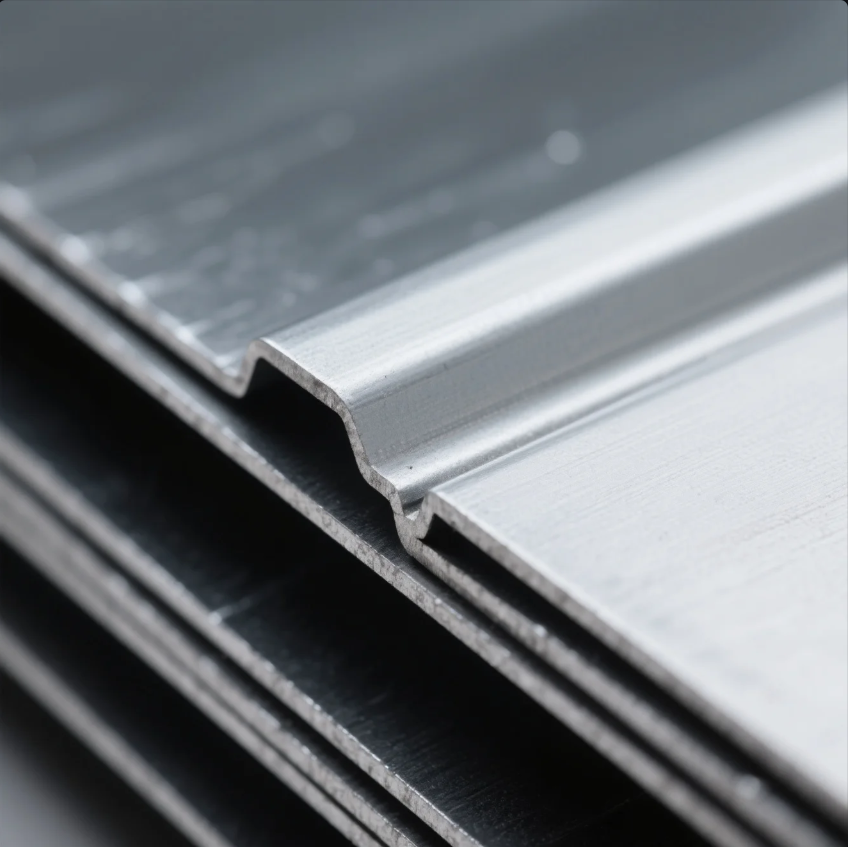

How do you prevent sharp edges in sheet metal?

The best edge is one that never gets sharp in the first place.

Use smart design choices like rounding corners, adding hems, and allowing space for post-cut edge smoothing.

At Prime, we provide free DFM (Design for Manufacturing) feedback, helping you reduce sharp features during the design stage—not after production.

Design-Based Sharpness Prevention

| Technique | Benefit |

|---|---|

| Radius Corners | Eliminates knife-like angles |

| Open Hemming | Folds metal back on itself, no edge exposed |

| Chamfers or Edge Breaks | Creates a bevel instead of a flat edge |

| Rounded Tool Paths | Prevents hard cut lines from leaving burrs |

This approach saves time and cost by reducing the need for extra finishing.

How to make tin edges not sharp?

Tin is soft but still sharp—especially on hand-cut or stamped parts.

Use a small file, 220–400 grit sandpaper, or a deburring blade to soften tin edges. You can also cover edges with plastic trim or fold them into a hem.

At Prime, we treat tinplate or galvanized parts with special care—ensuring no edge causes injury or coating defects.

Edge Dulling Options for Tin

| Method | Use Case |

|---|---|

| Hand Filing | Best for thin, flexible sections |

| Hemming | Structural or visible applications |

| Vinyl Trim or Tape | Quick coverage for exposed edges |

| Light Grinding | For thicker decorative tin sheets |

Even in high-speed production, we never ship parts with unprotected or razor-sharp edges.

Conclusion

To dull sheet metal edges, use sanding, filing, or hemming—and design with safety in mind from the start.

Need smooth, safe sheet metal parts with dull edges? Prime delivers precision edge finishing, ISO-certified quality, and expert design guidance. Contact us now for a custom quote and production-ready parts built for performance and safety.