How do you use a metal banding tool?

Securing heavy loads with loose or uneven straps can lead to shipping damage—or serious injury.

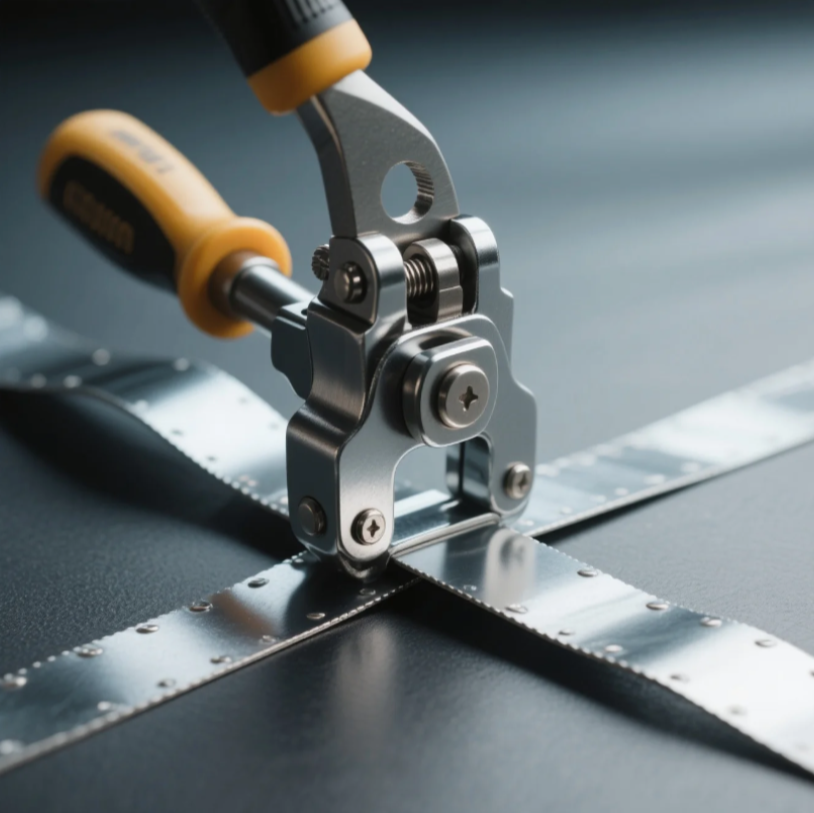

To use a metal banding tool, wrap the band around your item, feed it into the tensioner, tighten, apply a seal, and crimp it in place using a sealer or band-it tool.

At Prime, we use metal banding tools for securely bundling sheet metal panels, frames, and bulk industrial components during export packaging.

How to use a band it tool?

Strong packaging starts with proper tension and sealing.

Insert the banding strap into the BAND-IT tool, crank the handle to tighten around the load, cut off excess, and hammer the buckle closed.

At Prime, we use BAND-IT tools to ship metal assemblies and custom parts that need durable, tamper-proof strapping for global transport.

BAND-IT Tool Steps

| Step | Action |

|---|---|

| 1. Wrap strap around load | Overlap at least 3" (75mm) |

| 2. Insert into tool | Feed through tension handle |

| 3. Crank handle | Tighten band snugly |

| 4. Push tool down | Lock tension |

| 5. Cut and hammer seal | Snap strap and close buckle firmly |

Use stainless steel bands for outdoor or export use—they resist rust and hold tension longer.

What does a banding tool do?

Without tension, your straps won’t hold. That’s where the banding tool steps in.

A metal banding tool tightens, cuts, and secures steel or plastic strapping around packages, pallets, or industrial bundles.

At Prime, we rely on banding tools to secure sheet metal kits, frames, or finished enclosures to prevent shifting during truck or sea transport.

Banding Tool Functions

| Function | Purpose |

|---|---|

| Tensioning | Pulls strap tightly around load |

| Sealing | Locks strap with metal clips |

| Cutting | Removes excess after seal |

| Safety Holding | Prevents retraction and injuries |

We train our packing team to use certified tools—ensuring each shipment arrives intact.

How to use pallet banding tool?

Loose pallet loads cause damage during transit—banding locks everything in place.

To use a pallet banding tool, loop the metal or plastic strap around the pallet and product, insert it into the tensioner, tighten, and apply a metal seal.

At Prime, we ship bulk sheet metal orders using steel strapping and manual or pneumatic banding tools for extra load stability.

Pallet Banding Process

- Wrap band under pallet and over stacked goods.

- Feed into tensioner and crank tightly.

- Slide metal seal over band overlap.

- Use crimper to seal the strap firmly.

- Trim the band and check tension.

For heavy sheet bundles, steel strap with corner protectors keeps edges safe from crushing.

How do you use a strap binder tool?

Strap binders are heavy-duty tensioners—used when strength is non-negotiable.

A strap binder (or ratchet binder) tensions steel strapping by rotating a crank or handle. Once tight, apply a metal seal with a crimping tool to hold it.

At Prime, we use strap binders for oversized machinery frames, long sheet packs, and export pallets headed overseas.

Using a Strap Binder Tool

| Step | Description |

|---|---|

| Insert Strap | Thread through tensioning wheel |

| Rotate Handle | Tighten strap around bundle |

| Lock Position | Secure handle or ratchet when tight |

| Seal & Cut | Crimp metal seal and snip excess band |

Always wear gloves and eye protection—high-tension bands can snap back if mishandled.

Conclusion

To use a metal banding tool, wrap the strap, feed it through the tensioner, tighten, seal, and cut for a secure hold.

Need expert packaging for global shipping? Prime offers ISO-compliant export packing, banding, and palletizing for custom metal parts and sheet bundles. Contact us now for safe, professional logistics support.