How do you use a metal screw extractor?

Stripped or broken screws in metal parts can halt your whole assembly process.

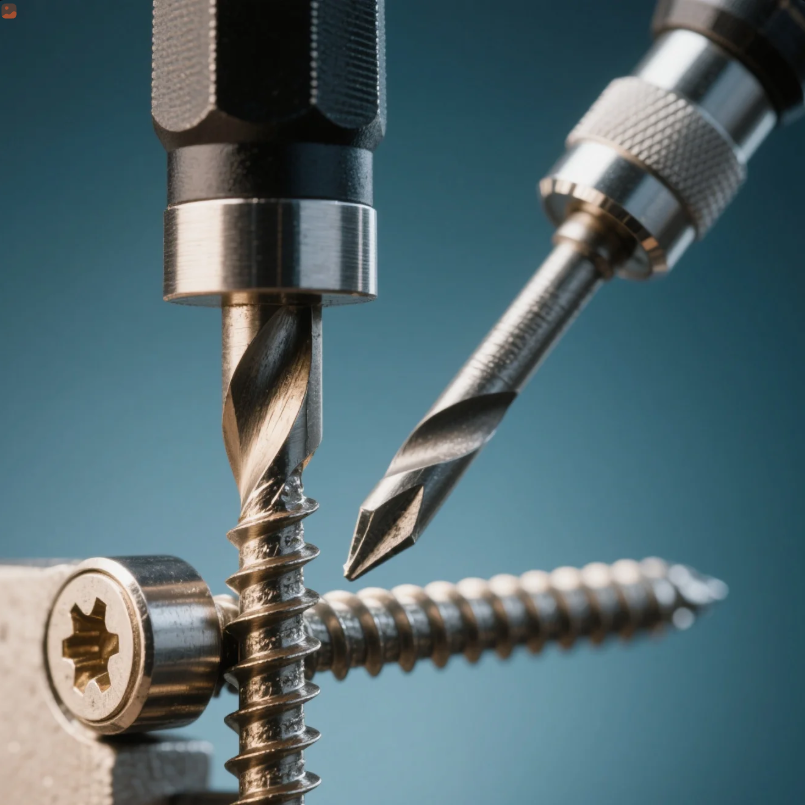

To use a metal screw extractor, drill a guide hole into the damaged screw, insert the extractor, and turn it counterclockwise to remove the screw.

At Prime, we use screw extractors during metal assembly rework or field repairs when fasteners break inside aluminum, stainless steel, or carbon steel parts.

How to use a screw extractor on metal?

Removing a damaged screw sounds tough—but it’s manageable with the right tool.

First, center-punch the broken screw. Then, drill a pilot hole using a bit slightly smaller than the extractor. Insert the extractor and turn it counterclockwise to back the screw out.

At Prime, we do this carefully on machined components and tapped holes to avoid damaging the thread.

Screw Extraction Process

| Step | Tool Needed |

|---|---|

| 1. Center Punch | Prevents drill wandering |

| 2. Drill Pilot Hole | Use slow speed, firm pressure |

| 3. Insert Extractor | Twist counterclockwise |

| 4. Back Out Screw | Remove slowly and steadily |

Apply penetrating oil if the screw is seized from corrosion.

Do I need a drill for a screw extractor?

A steady hand—and a drill—can make all the difference.

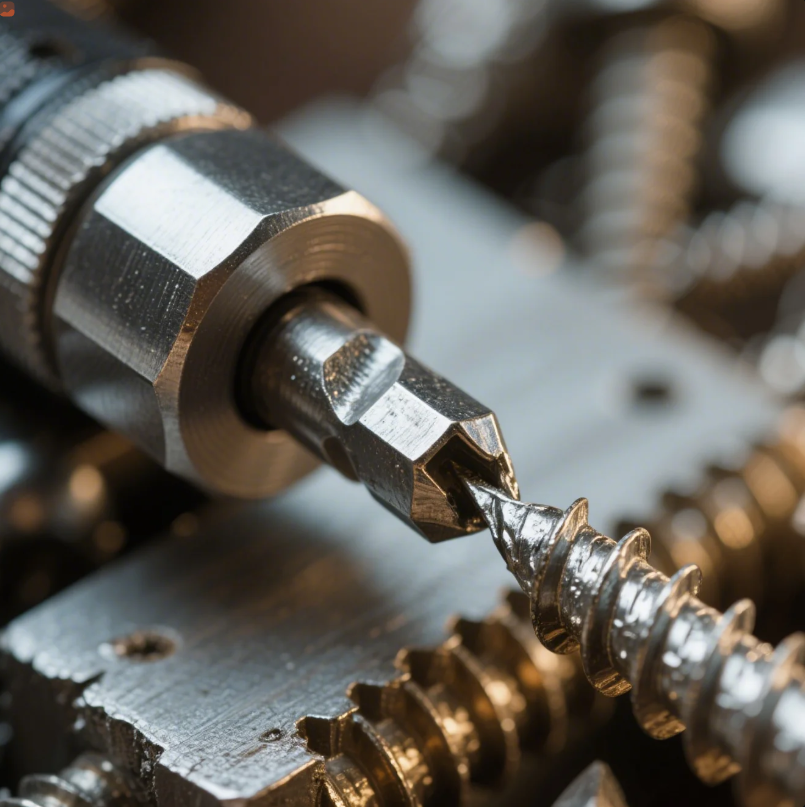

Yes, you need a drill to create a pilot hole in the damaged screw so the extractor has a place to grip.

At Prime, we use slow-speed corded drills with high-speed steel (HSS) bits to avoid overheating or damaging nearby parts.

Drill Bit Tips

| Material Type | Recommended Drill Bit |

|---|---|

| Stainless Steel | Cobalt HSS Bit |

| Aluminum | Standard HSS Bit |

| Hardened Steel | Carbide Bit (use slowly) |

Use drill bits 1–2 mm smaller than the extractor’s shank for proper grip.

Do you hammer in a screw extractor?

Sometimes the extractor needs help seating—but don’t overdo it.

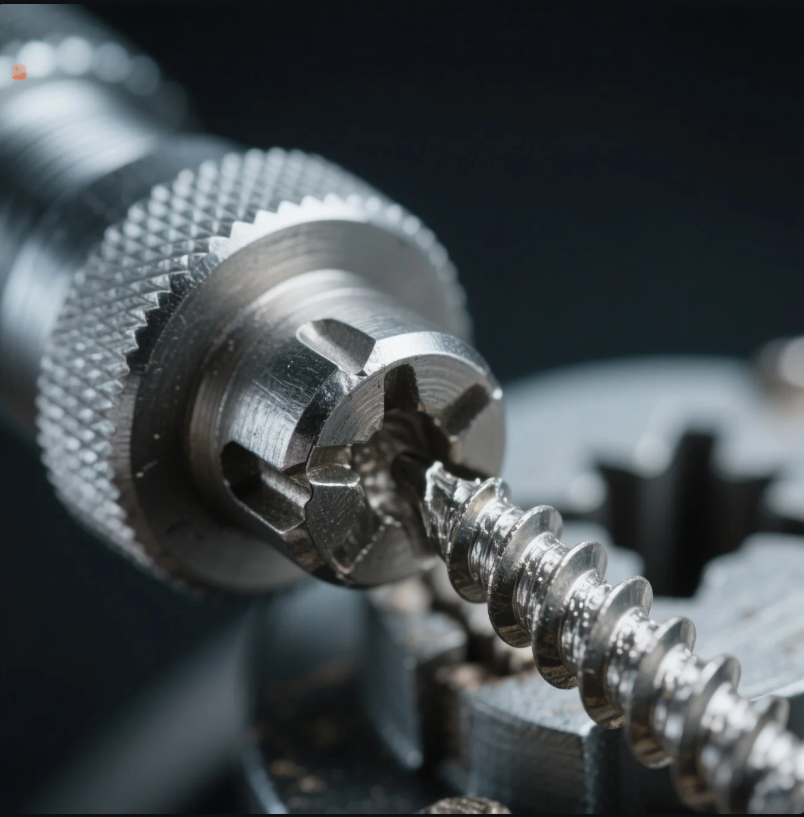

Yes, you lightly tap the screw extractor into the drilled hole using a hammer, just enough to grip. Do not hammer forcefully or you’ll risk breakage.

At Prime, we tap the extractor in just enough to seat it snugly—especially when working on tight stainless fasteners or threadlocked bolts.

Hammering Tips

| Task | Precaution |

|---|---|

| Light Tap Only | Prevents extractor tip damage |

| Use Center Punch First | Keeps drill aligned |

| Avoid Overdrive | Breaking extractors is common |

Always use extractors made from hardened tool steel for reliability.

How do you use a Snap-on screw extractor?

Snap-on extractors offer pro-grade grip—but technique still matters.

With a Snap-on extractor, drill a centered pilot hole in the screw, gently tap the extractor in, then use the included T-handle or wrench to turn it counterclockwise.

At Prime, we’ve used Snap-on tools in toolroom rework and maintenance kits for removing seized fasteners without damaging the base material.

Snap-on Extractor Use Guide

| Step | Tool Included |

|---|---|

| Drill Pilot Hole | Drill bit (or buy separately) |

| Tap Extractor | Hammer, softly |

| Turn with Handle | T-handle or adjustable wrench |

| Remove Screw | Twist slowly with control |

Apply rust remover or heat (if safe) on stuck screws before starting.

Conclusion

To use a screw extractor, drill a pilot hole, gently insert the extractor, and twist counterclockwise to remove the damaged screw.

Need help recovering parts from fastener failures? Prime offers thread repair, precision tapping, and custom rework services on all sheet metal assemblies. Contact us today for a quote and reliable recovery support.