How Does Custom Metal Fabrication Work?

When you need a metal part made to spec, fabrication turns ideas into hardware.

Custom metal fabrication is the process of cutting, forming, and assembling raw metal into a finished product based on a client’s design. It involves multiple steps, materials, and tools — all customized to meet precise requirements.

Let’s look at how it works, what it costs, and the most common techniques used.

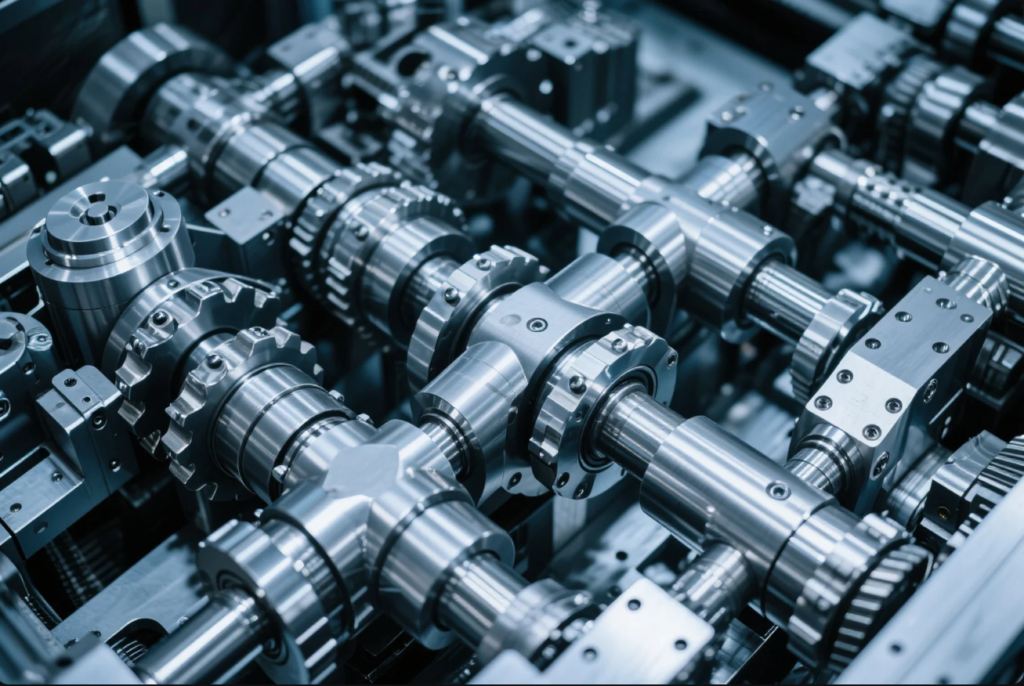

How Does Metal Fabrication Work?

The process starts with your design — and ends with a finished part ready to use.

Metal fabrication transforms raw materials like sheet, tube, or billet into a usable part using industrial machines and skilled labor.

Key Steps in the Fabrication Workflow

| Step | What Happens | Example |

|---|---|---|

| Drawing Review | Engineers study the part requirements | Analyze CAD or sketches |

| Cutting | CNC lasers, plasma, or saws cut shape | Flat panels, brackets |

| Bending/Forming | Press brakes or rollers bend material | Cabinets, housings |

| Welding/Joining | Parts are joined by MIG or TIG | Frames, mounts, supports |

| Finishing | Surface treated or coated | Polishing, painting, plating |

| QC + Packaging | Final inspection and export packaging | Labeling, foam wrap, boxing |

At Prime, our fabrication lines integrate all steps under one roof. We support fast turnarounds, ISO-certified quality, and global delivery.

How Much Does Custom Metal Fabrication Cost?

Price varies depending on part complexity, material, and quantity.

Simple parts cost \$50–\$150. Complex welded or coated assemblies can range from \$300 to \$3,000+.

What Impacts Cost?

| Cost Driver | Effect on Price | Notes |

|---|---|---|

| Material Type | High | Stainless & titanium cost more |

| Tolerance & Finish | Medium to High | Tight specs need more labor |

| Welding Required | High | Increases time and inspection |

| Quantity | High | Bulk reduces unit cost |

| Surface Treatment | Medium | Adds steps, labor, packaging |

At Prime, we give fast, accurate quotes after reviewing your files or photos. We help you optimize designs to save cost without losing function.

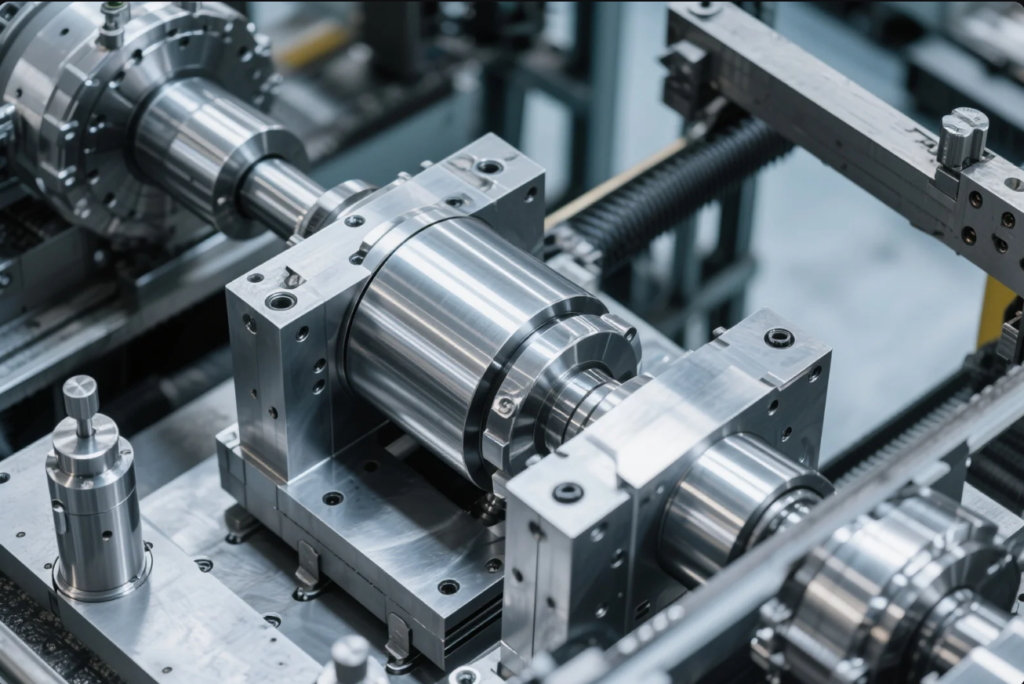

What Is Custom Metal Fabrication?

When standard parts don’t fit — custom fabrication delivers.

It means making metal components from scratch based on customer drawings, rather than buying pre-made or modifying stock.

Who Needs Custom Metal Work?

- Engineers building unique products

- Machinery manufacturers needing special frames or guards

- Builders installing metal elements to fit custom spaces

- OEMs who require branded or private label hardware

We serve all of these industries with custom sheet metal, CNC machining, welding assemblies, and surface-treated parts.

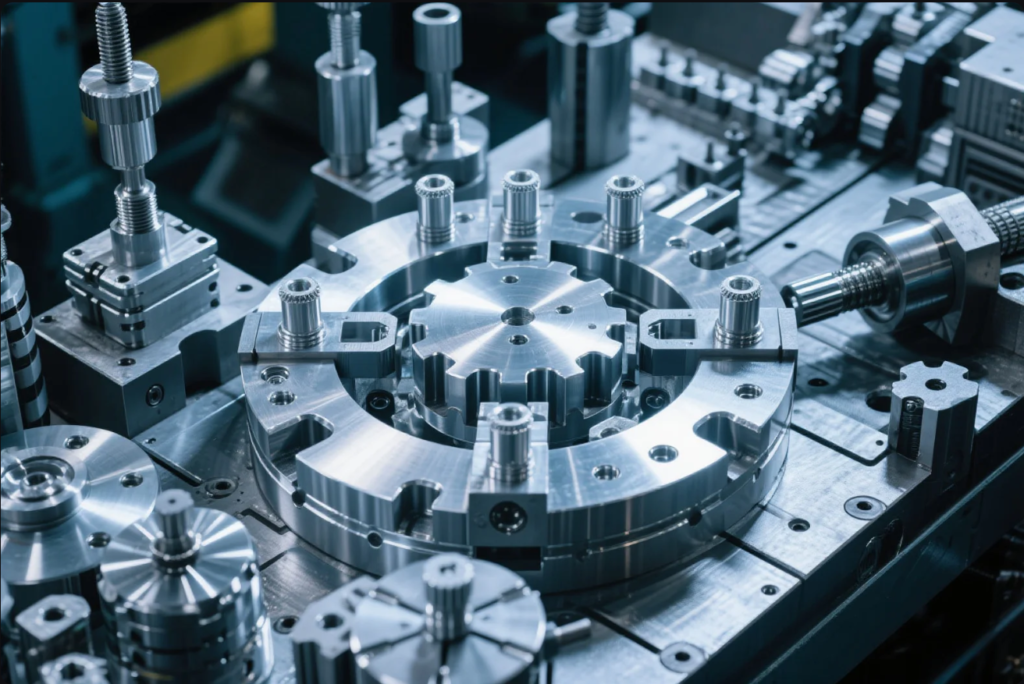

What Are the Three 3 Types of Metal Fabrication?

Most metal parts are made using a mix of three core techniques.

The three basic types of fabrication are cutting, forming, and assembly (usually welding or fastening).

Key Fabrication Methods

| Type | Description | Common Tool/Process |

|---|---|---|

| Cutting | Removing material for shape/holes | Laser, plasma, waterjet, saws |

| Forming | Bending or shaping metal | Press brake, rollers, stamping |

| Assembly | Joining parts into one unit | MIG/TIG welding, fasteners |

At Prime, we combine all three in one order — often starting with CNC cutting, moving to bending, then final assembly with welding and surface coating.

FAQs

Q1: What files do you need to start a project?

We accept STEP, DXF, IGES, or even hand sketches for quoting.

Q2: What metals can you fabricate?

Aluminum, stainless steel, mild steel, copper, and titanium.

Q3: Can I order one part or small batch?

Yes. We support low-volume and prototyping runs.

Q4: Do you provide coating or painting?

Yes. Powder coating, anodizing, plating, and more.

Q5: Where do you ship?

We export to North America, Europe, the Middle East, and more — with reliable logistics partners.

Contact Prime

Need a part made exactly to spec? Let’s build it — fast, precise, and globally delivered.

📞 Start your custom fabrication project today:

👉 Visit: https://primecustomparts.com

📧 Email: [email protected]

Prime is your trusted partner for small parts, large assemblies, and everything in between.