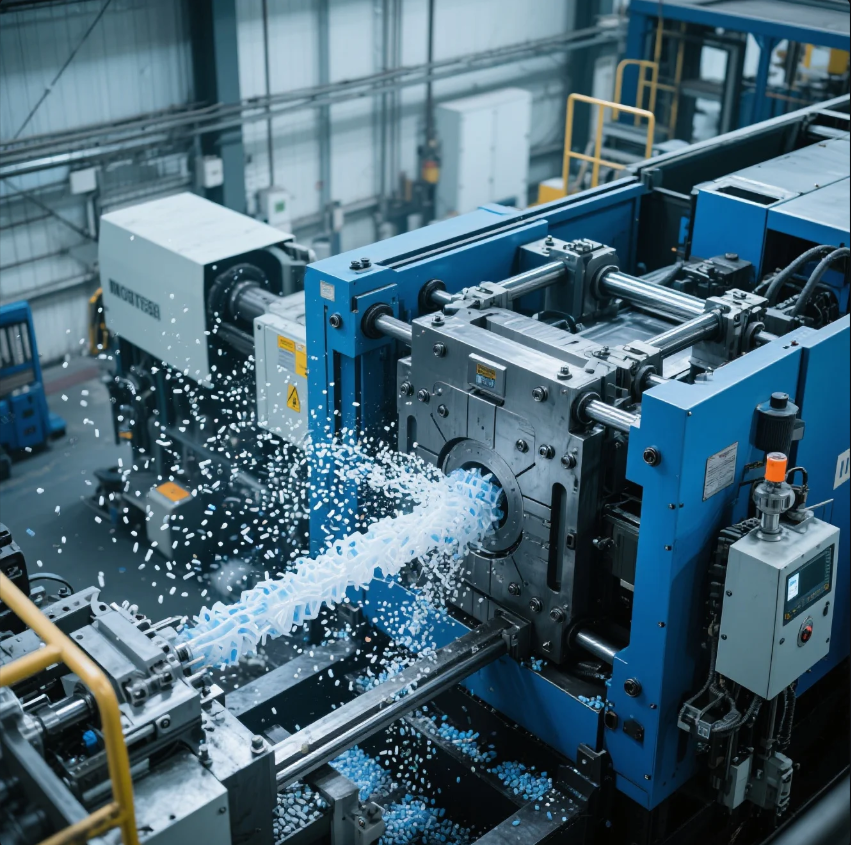

How long do injection molding machines last?

Buyers often wonder how long injection molding machines will last — especially before investing tens of thousands of dollars.

A well-maintained injection molding machine can last 15 to 30 years, depending on usage, quality, and maintenance.

At Prime, we work with factories running both new and legacy machines. We help clients extend machine life by supplying custom plastic parts optimized for consistent production.

What is the useful life of molding machine?

Machine life depends on load cycles, material type, and maintenance discipline.

Most injection molding machines have a useful life of 15–30 years if properly maintained.

One of our long-term clients in North America runs a 20-year-old 200-ton press. With regular oil checks and upgraded control units, it’s still producing thousands of custom plastic parts monthly.

Factors Affecting Machine Longevity

| Factor | Impact on Life Span |

|---|---|

| Daily cycle count | Higher counts reduce life faster |

| Material used | Abrasive plastics cause more wear |

| Maintenance | Poor servicing shortens lifespan |

| Machine brand | High-end machines last longer |

At Prime, we often help clients assess whether to maintain, upgrade, or outsource production based on their machine’s performance and cost-per-part metrics.

How much does it cost to buy an injection molding machine?

The purchase price depends on clamping force, build quality, and control system complexity.

Injection molding machines cost between \$5,000 and \$250,000+, depending on size and features.

A client in the Middle East considered a 300-ton machine for consumer goods. After full ROI analysis with our team, they chose to outsource to Prime — cutting costs by 40% while avoiding maintenance and labor overhead.

Price Ranges by Tonnage

| Tonnage | Machine Type | Price Estimate |

|---|---|---|

| 15–50 tons | Small parts | \$5,000 – \$15,000 |

| 100–300 tons | Mid-size production | \$30,000 – \$80,000 |

| 400–1000+ tons | Industrial products | \$100,000 – \$250,000+ |

We support clients with technical comparisons and can take over production entirely using our 10 in-house lines.

Who makes the best injection molding machines?

Not all machines are equal — brands differ in precision, energy use, and support.

Top injection molding machine brands include Arburg, Engel, Haitian, Sumitomo, and Nissei.

At Prime, we operate a mix of premium Asian and European brands in our facility. This gives us flexibility to deliver ISO-certified plastic parts to clients worldwide — whether they need large panels or micro molded items.

Leading Global Brands Overview

| Brand | Known For | Origin |

|---|---|---|

| Arburg | High precision, servo controls | Germany |

| Haitian | Competitive pricing, reliability | China |

| Engel | Fully electric and hybrid models | Austria |

| Sumitomo | Ultra-precision applications | Japan |

| Nissei | High efficiency, compact design | Japan |

If you’re unsure which machine fits your needs, you can outsource to Prime while avoiding upfront investment.

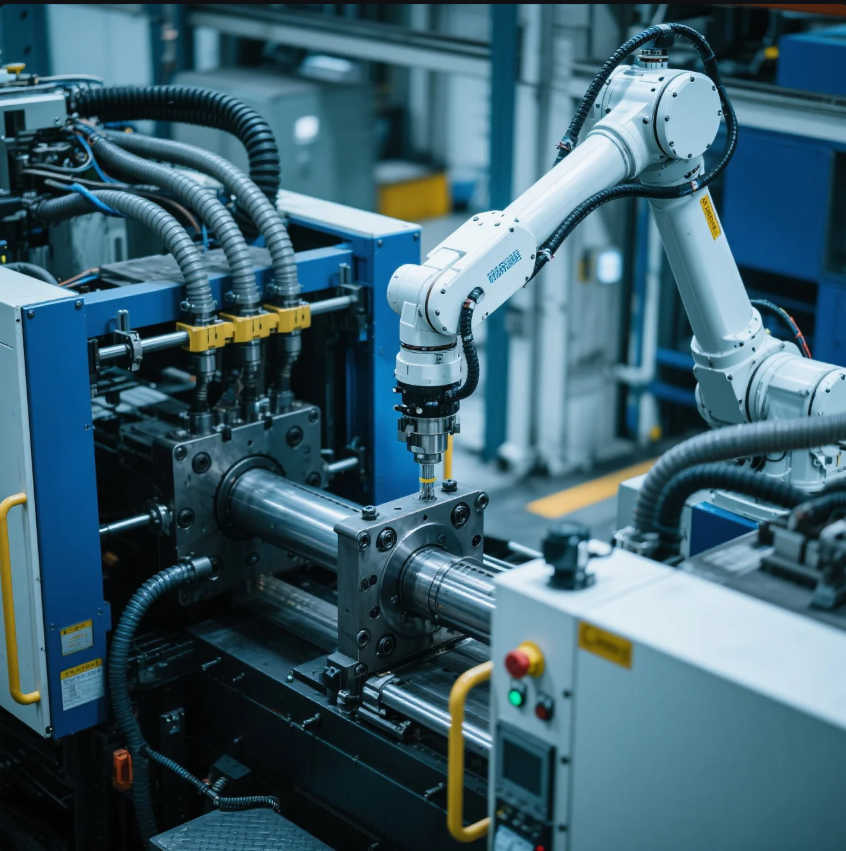

What is the disadvantage of injection molding machine?

Molding machines offer speed, but also come with challenges many buyers underestimate.

Disadvantages include high upfront costs, long setup times, limited flexibility, and intensive maintenance needs.

We’ve advised dozens of clients not to buy machines too early. One European buyer nearly spent \$70,000 on a 250-ton system. Instead, they began working with Prime — scaling gradually while we handled tooling and production.

Key Disadvantages of Owning Molding Machines

| Issue | Why It Matters |

|---|---|

| Capital intensity | Equipment + mold costs exceed \$100,000 |

| Setup limitations | Mold changes can take hours |

| Labor + maintenance | Skilled technicians required |

| Flexibility | Not ideal for product revisions |

Prime’s B2B plastic part service lets you test designs, change volumes, and adjust specs — without machine risk.

Conclusion

Injection molding machines last 15–30 years — but outsourcing can give you that output without ownership burden.

Want consistent, long-life custom plastic parts production without buying a machine? Prime offers ISO-certified molding, expert consultation, and global shipping. Use our website to request a free quote, ROI comparison, or part analysis — and make better decisions for your business.