TEMPLATE_START

How long does it take to become a good blacksmith?

Many beginners worry about how long it takes to master blacksmithing.

This article explains the learning curve, investment, and earning potential of modern blacksmiths.

Mastery takes time—but the journey builds real skill and value.

How many years does it take to become a blacksmith?

Buyers often ask how long it takes to go from beginner to pro.

It typically takes 3–5 years of consistent practice to become a skilled blacksmith.

Learning blacksmithing combines skill, muscle memory, and materials knowledge

Like any craft, blacksmithing requires hands-on time to develop control, heat awareness, and metalworking intuition. Some reach competence in a year—but true fluency takes longer. This is why Prime partners with blacksmithing schools, OEM trainers, and DIY kit suppliers to support learners at all levels.

| Skill Level | Time Required (Approx.) | Key Milestones |

|---|---|---|

| Beginner | 0–6 months | Learn heat control, hammer technique |

| Intermediate | 1–2 years | Create functional tools or art |

| Advanced | 3–5 years | Sell goods, teach, scale up |

| Master level | 5+ years | Run business, design product lines |

At Prime, we help new blacksmiths shorten the learning curve by offering pre-forged blanks, starter tool sets, and ISO-grade material parts—ready to use from day one.

How hard is it to be a blacksmith?

Buyers want to know what they’re really getting into.

Blacksmithing is physically demanding and mentally challenging—but deeply rewarding.

The job is part craft, part endurance

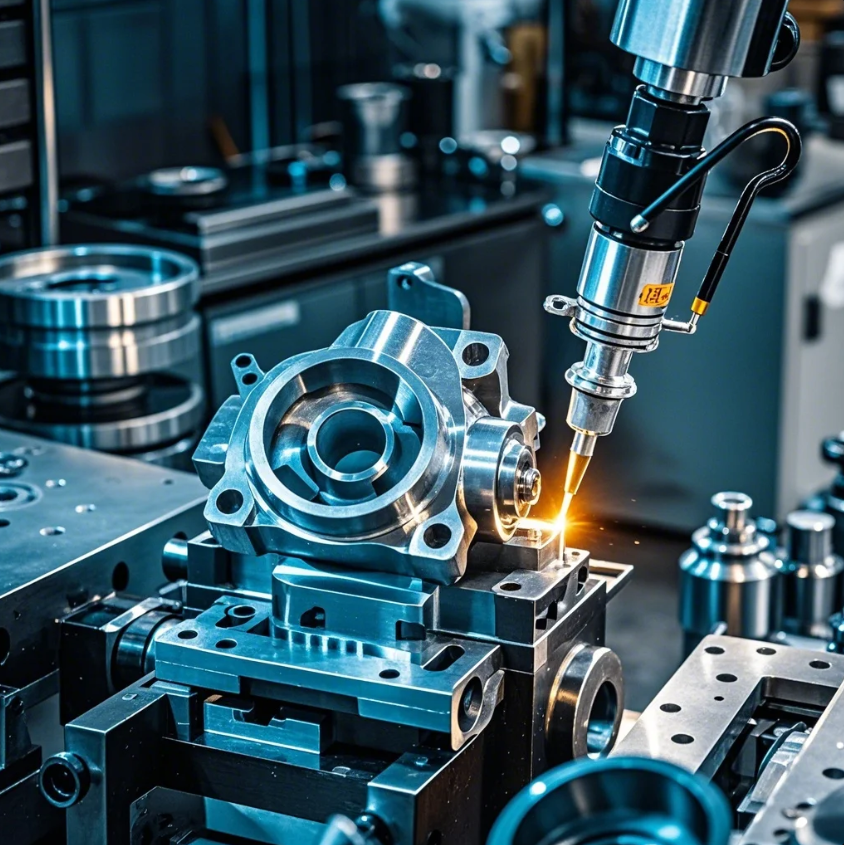

Forging requires focus, patience, and muscle control. You’ll deal with hot metal, heavy tools, and constant motion. But it’s also meditative—many find it therapeutic. Today’s blacksmiths often use power tools to reduce strain while improving output.

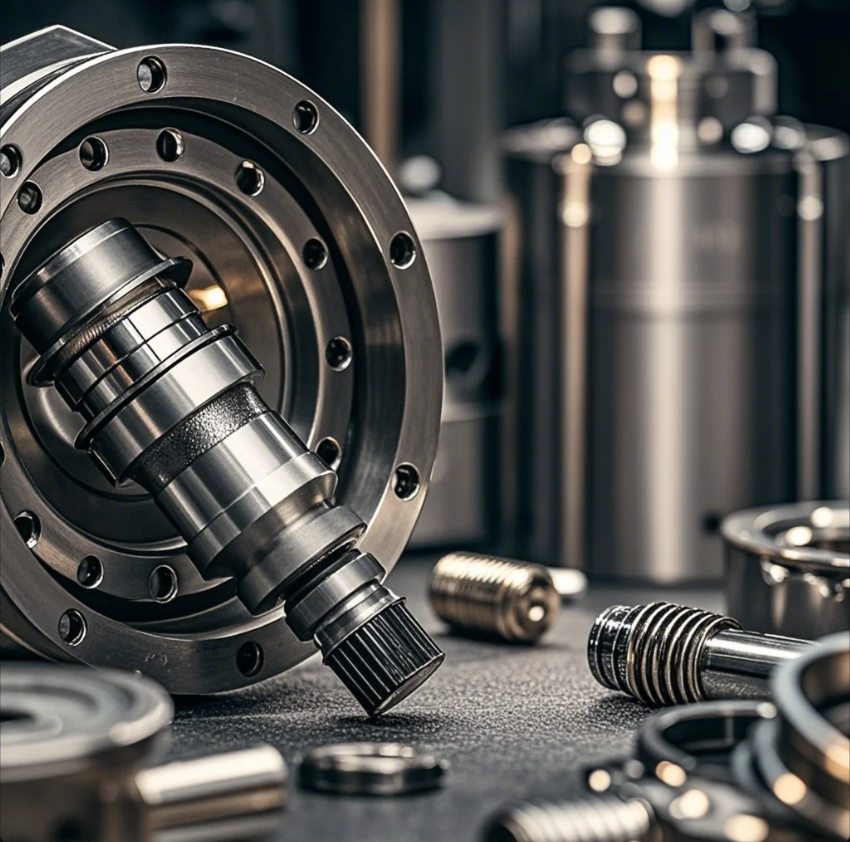

At Prime, we work with professional smiths and OEM clients who need ergonomic, efficient equipment, such as:

- Forged hammer heads (custom weight options)

- Lightweight CNC anvils

- Adjustable forging vises

- ISO-standard mild steel blanks

| Challenge | Solution | Prime’s Role |

|---|---|---|

| Physical fatigue | Ergonomic hammers, tool upgrades | Custom hammer head forging |

| Heat & safety | Better tongs and vises | Forged tongs, vise assemblies |

| Inconsistent material | High-grade steel supply | Pre-cut ISO-certified bars |

| Time management | Project kits | Ready-to-use forging components |

Blacksmithing isn’t easy—but smart tools and trusted suppliers make the difference.

Do blacksmiths make good money?

Buyers also want to know if blacksmithing can become a real business.

Yes—many blacksmiths earn $30,000–$100,000+ per year, depending on their niche and scale.

Profit depends on branding, product type, and efficiency

Modern blacksmiths succeed by selling high-margin goods—like knives, custom furniture hardware, or hand-forged tools. Others teach classes or offer restoration services. Prime helps blacksmiths scale by supplying low-cost, high-quality forging blanks and OEM tool parts to cut production costs.

| Blacksmith Focus | Earning Potential (Annual) | Notes |

|---|---|---|

| Custom Knife Maker | $50,000–$120,000 | High markup, steady demand |

| Hardware / Brackets | $40,000–$90,000 | B2B and retail opportunities |

| Instructor / Workshop | $30,000–$80,000 | Teaching + product sales |

| Tool Manufacturing | $30,000–70,000 | Requires bulk efficiency |

Our clients often start small, then expand using Prime’s scalable supply system—custom forged components, fast lead times, and branding support.

Is blacksmithing an expensive hobby?

Many hesitate because they think blacksmithing is cost-prohibitive.

Blacksmithing can start affordably—basic kits begin around $500, while pro setups run $5,000+.

It depends how far you want to go

You can start with a small propane forge, anvil, hammer, and tongs. As your skills grow, you can invest in power hammers, larger anvils, and CNC tooling. Prime supplies components for both hobbyists and full-scale workshops.

| Item | Entry Cost | Prime Solution |

|---|---|---|

| Hammer + Tongs Set | $50–$150 | Forged OEM sets |

| Propane Forge | $200–$500 | Forge shell kits, burner sets |

| Anvil (100 lbs) | $200–$800 | CNC or cast steel models |

| Grinder | $100–$300 | Motor assemblies available |

| Raw Materials | $50–$200/month | ISO-certified steel blanks |

We help blacksmiths reduce costs by offering bulk pricing, custom part bundles, and starter sets for education and resale.

结论

Becoming a good blacksmith takes years—but with smart tools, the right materials, and reliable supply chains, success is within reach.

At Prime, we help new and experienced blacksmiths grow—faster, safer, and more profitably. From starter tool kits to ISO-certified forged components, we supply everything you need to succeed in this age-old craft.

👉 Contact us today through our website to get a free quote, tool guide, or a custom plan to launch your blacksmithing business. We deliver worldwide—fast, efficient, and with over 30 years of forging expertise.

TEMPLATE_END