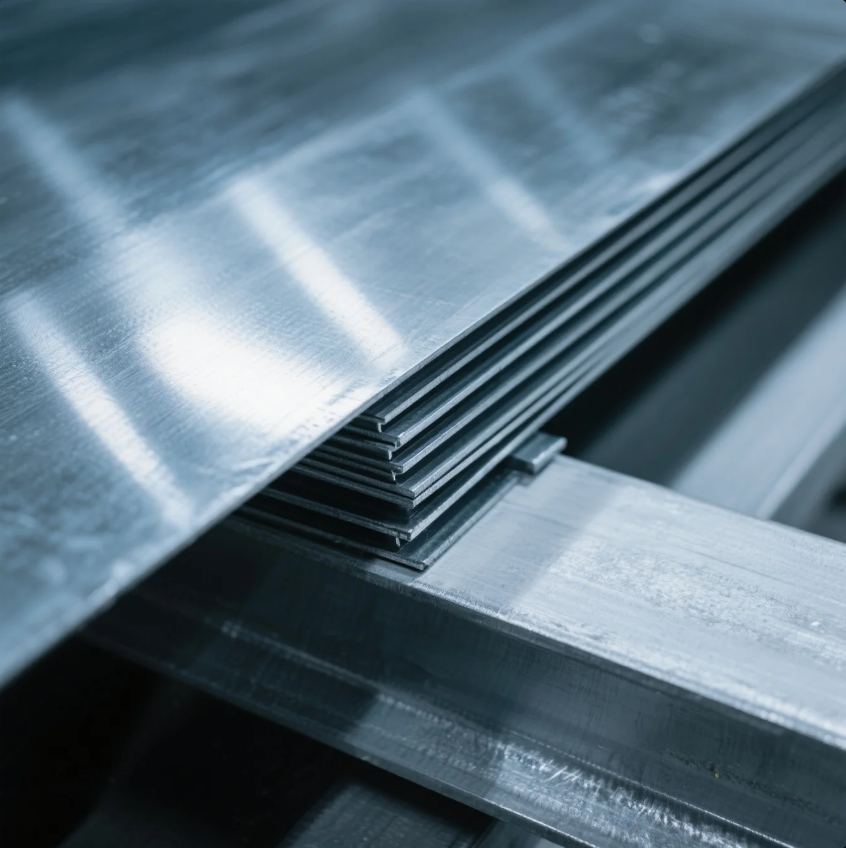

How long should a hem on sheet metal be?

Too short a hem can lead to tearing, weak edges, or rejected parts.

The hem on sheet metal should be at least 4× the material thickness. This ensures safe bending, proper closure, and structural strength.

At Prime, we follow this rule across all ISO-certified sheet metal parts, from enclosures to machine covers, ensuring every hem adds durability—not defects.

What is the minimum hem length for sheet metal?

Undersized hems often fail under load or create sharp, exposed edges.

The minimum hem length in sheet metal is 4 times the material thickness. This length ensures a clean fold and safe part performance.

At Prime, we use this baseline for all bent edge protection and reinforcement features, and we adjust for function and load.

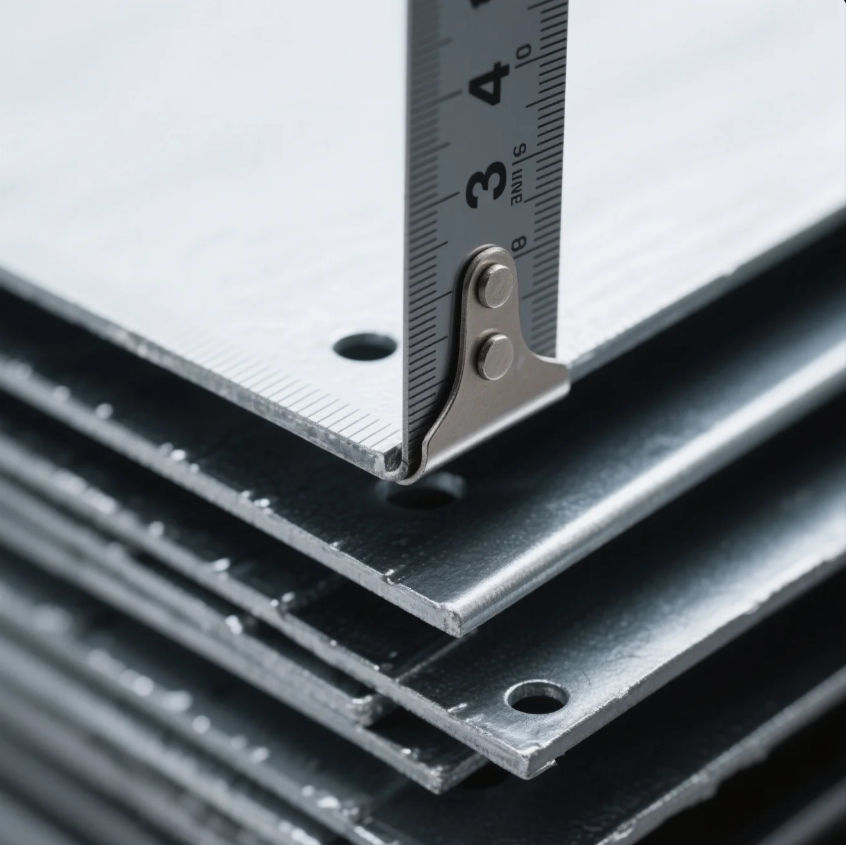

Minimum Hem Length Guidelines

| Material Thickness | Minimum Hem Length |

|---|---|

| 0.8 mm | 3.2 mm |

| 1.0 mm | 4.0 mm |

| 1.5 mm | 6.0 mm |

| 2.0 mm | 8.0 mm |

For closed or teardrop hems, additional allowance may be required for proper folding.

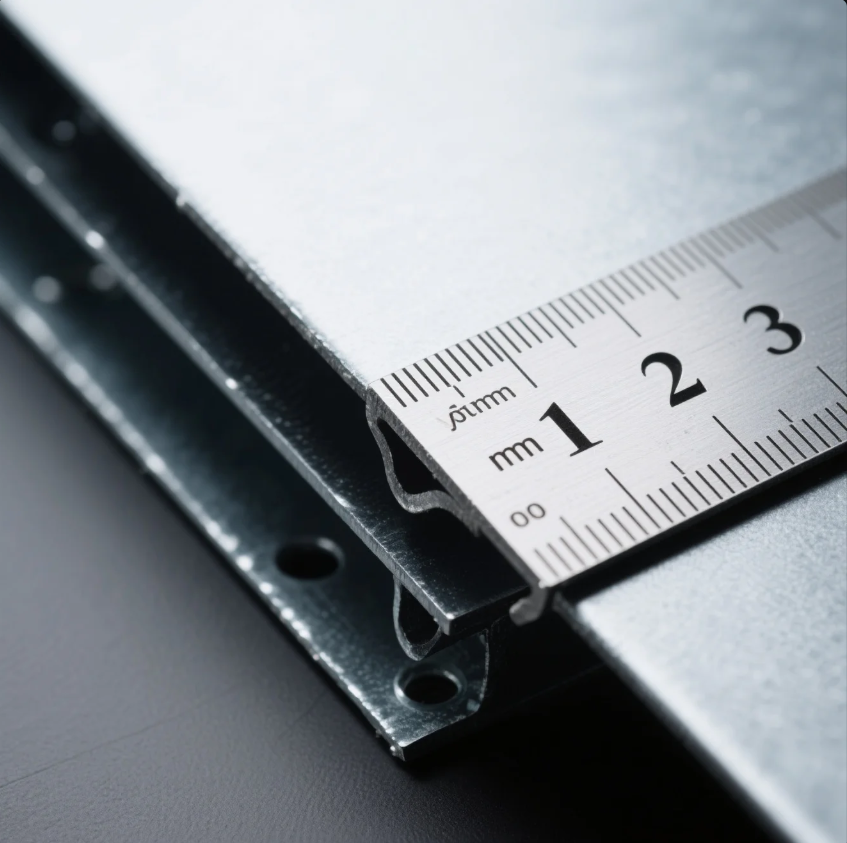

How many inches should a hem be?

Switching to imperial units? Here’s what to know.

In inches, the hem should be a minimum of 0.16" per 0.04" thickness. For 16-gauge steel (≈0.06"), a minimum hem length of 0.24" is recommended.

At Prime, we routinely handle both metric and imperial specs for export sheet metal assemblies, ensuring consistency in international projects.

Inch-Based Hem Length Examples

| Gauge (Mild Steel) | Approx. Thickness (in) | Min. Hem Length (in) |

|---|---|---|

| 22 | 0.031" | 0.12" |

| 18 | 0.048" | 0.19" |

| 16 | 0.060" | 0.24" |

| 14 | 0.075" | 0.30" |

Need a conversion? Our quoting team helps match global spec sheets to correct shop values.

What is the hem allowance for sheet metal?

Allowance isn’t just bend length—it’s extra material to fold correctly.

Hem allowance is the extra material length required in the flat pattern to form the hem. It varies with thickness, bend type, and hem style.

At Prime, we calculate hem allowances digitally using CAD/CAM software—so your custom sheet parts close accurately without rework.

Common Hem Allowances

| Hem Type | Approx. Allowance (Flat Pattern) |

|---|---|

| Open Hem | 1.5 × thickness + radius |

| Closed Hem | 2.0 × thickness + tight radius |

| Tear Drop Hem | 2.5 × thickness + spacing gap |

We also test allowances on new materials to validate the best forming strategy before mass production.

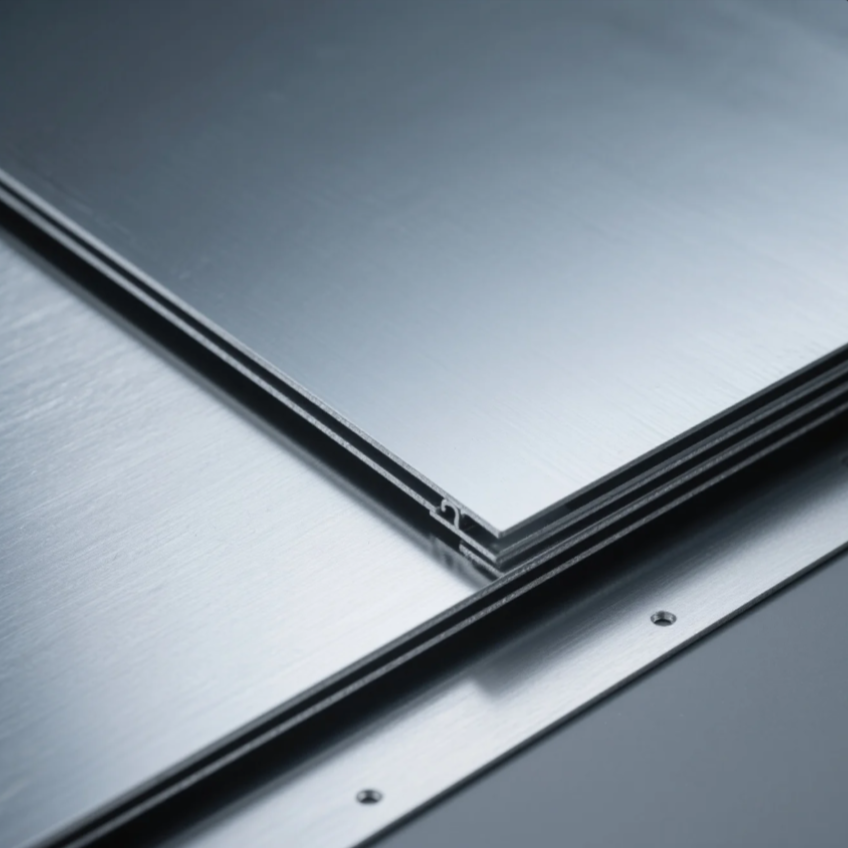

What is the hem feature in sheet metal?

Hems do more than make the part look neat.

A hem is a folded edge that strengthens sheet metal, hides sharp corners, and adds structural or visual finish.

At Prime, we use hem features in metal cabinets, control boxes, and automotive panels, tailoring the type of hem to each function.

Types of Hems and Their Uses

| Hem Type | Best For |

|---|---|

| Open Hem | Safety edges, cosmetic trims |

| Closed Hem | Rigid flanges, structural edges |

| Tear Drop Hem | Aesthetic curves, visible edge styling |

Adding hems also improves stiffness and reduces cutting injuries during assembly or transport.

Conclusion

A sheet metal hem should be at least 4× the material thickness for safe and reliable folding.

Need help designing professional, production-ready hemmed parts? Prime offers DFM optimization, ISO-certified forming, and full metal part fabrication—delivered with precision and speed. Contact us today for expert guidance and a fast custom quote.