Why Are Custom Stamping Parts Essential for Industrial Equipment Reliability and Performance?

Custom stamping parts reduce downtime, vibration, and maintenance. They drive precision and productivity in industrial equipment.

This extensive guide explains stamping benefits, materials, tooling, QA, logistics, and why Prime stands out as your trusted stamping partner.

Industrial Problems Caused by Generic Stamping Parts

Generic parts often fail to meet real-world fitment and tolerance requirements.

They cause vibration, delays, and unexpected failures that hurt your production timeline.

According to Engineering.com, misaligned or poorly formed parts account for up to 60% of stoppages in automated systems.

Common problems:

- Parts need rework before assembly

- Fitment issues with shafts, brackets, or covers

- Higher stress on joints, resulting in early failure

- Increased maintenance and spare part use

How Custom Stamping Solves Industrial Efficiency Issues

Custom stamping provides unmatched control over size, geometry, and functionality.

It ensures reliability, reduces cost over time, and fits your machinery exactly.

| Custom Feature | Advantage |

|---|---|

| Hole/slot placement | Perfect interface with mounting frames |

| Embossed shapes | Strength without added weight |

| Tailored material | Better stress/corrosion response |

| Tight tolerance | No vibration or extra machining |

| Consistent batch QC | Predictable long-term performance |

See Thomasnet’s guide to understand how custom dies reduce rework and improve cost-per-part metrics.

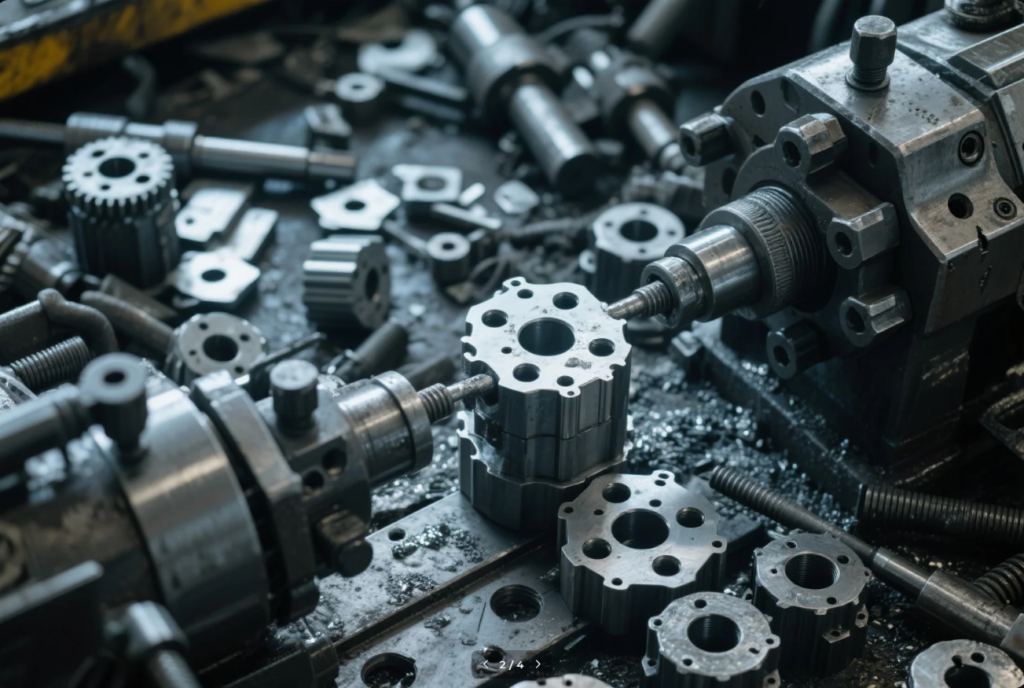

Prime’s Technical Capabilities and Tools

We provide tooling, prototyping, full-scale production, and secondary processes—all in-house.

Our tooling team collaborates closely with clients from first sketch to final shipment.

Our Equipment

- 30–250T mechanical presses

- Coil feeders and straighteners

- Progressive die stamping

- Deep drawing presses

- Servo-based feeders for ±0.1 mm control

In-house Services

- Die design and fabrication

- CNC trimming and threading

- Laser marking, MIG/TIG welding

- Anodizing, plating, polishing

All manufacturing is ISO 9001-certified with no outsourcing.

Materials and Coating Options for Stamping Parts

Choosing the right base metal and surface treatment is key to performance.

Prime supports over 15 stamping metals, tailored to each application.

| Material | Best Use | Properties |

|---|---|---|

| SPCC / Q235 Steel | General frames, brackets | Easy to form, cost-efficient |

| 304/316 Stainless | Food-grade, clean-room parts | Corrosion resistant, durable |

| 5052 Aluminum | Covers, casings, automation panels | Lightweight, corrosion-resistant |

| Brass / Copper | Connectors, EMC covers | Conductive, aesthetic |

| Galvanized Steel | Outdoor brackets, transport rails | Rustproof, low-cost |

Compare with Metal Supermarkets material properties database.

Surface Finish Options

Surface finish affects corrosion resistance, aesthetic, and wear.

We offer coatings compliant with RoHS, REACH, and OEM standards.

| Finish Type | Application | Benefits |

|---|---|---|

| Powder coating | Machinery housing | Durable, colored protection |

| Zinc/Nickel plating | Steel brackets | Corrosion barrier |

| Anodizing (Al) | Panels, guides | Oxidation resistance, colorable |

| Brushing / Polishing | Aesthetic covers | High-end appearance, smooth touch |

| Electropolishing | Cleanroom equipment | Sanitary, bright finish |

See industrial finish guidelines at Finishing.com.

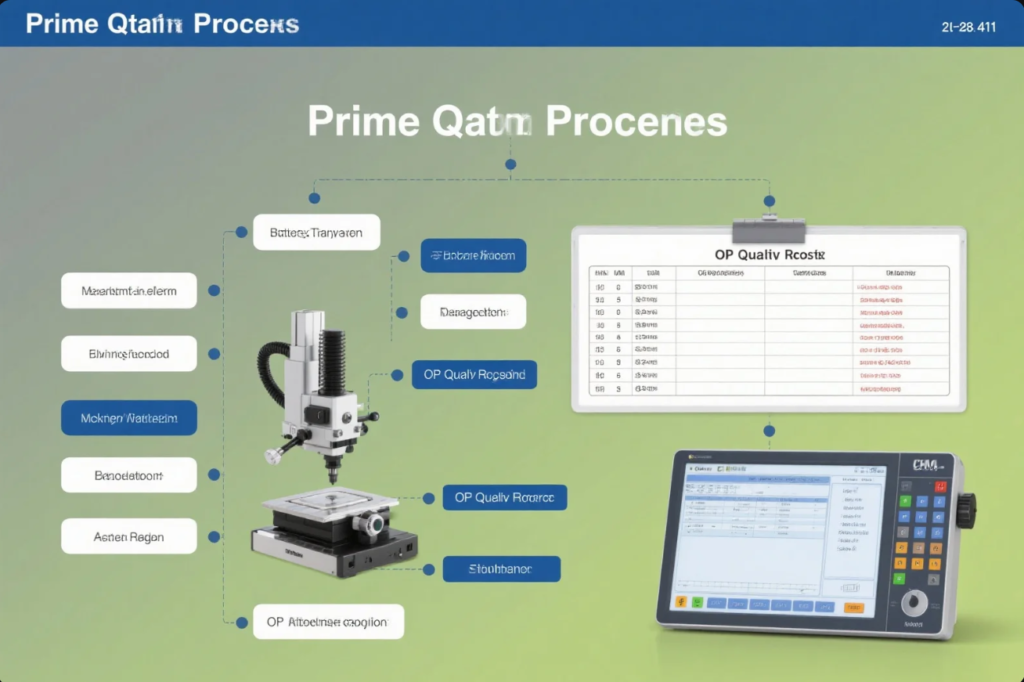

Precision, Quality Control and Inspection Processes

Your product is only as strong as your process.

We perform full QC before, during, and after stamping to guarantee consistency.

Prime QA Coverage

- CMM (Coordinate Measuring Machine) for first article inspection

- Optical scanners for batch detection

- Statistical process control (SPC) in production

- Surface roughness and coating thickness tests

- Full traceability by batch and serial number

We provide reports with every order: material certificates, inspection logs, PPAP files.

Protective Packaging, Logistics & Export Readiness

Perfect parts need perfect protection.

We offer multi-layered packaging that preserves part integrity through ocean or air freight.

| Packaging Layer | Function |

|---|---|

| PE/VCI bag | Prevent rust/moisture corrosion |

| Foam wrap | Protect from impact or deformation |

| Carton box | Organize by lot, label clearly |

| ISPM-15 crate | Export compliance + impact resistance |

Our logistics partners include DHL, UPS, Maersk, and Cainiao for global routes.

Case Studies: Industry Applications

Packaging OEM – Germany

We supplied high-volume progressive die brackets:

- Reduced installation time by 40%

- Improved long-term alignment and reduced scrap

- Maintained 0.02 mm tolerance across 20,000 pcs

Robotic Integrator – North America

Stamped sensor mounts from 5052 aluminum:

- Laser etched part IDs

- Anodized in three colors for robot zones

- No post-assembly adjustments required

Food Processing Equipment – UAE

Stamped 316 stainless steel brackets:

- Electropolished

- NSF-compliant

- Zero corrosion after 3 years continuous use

Ordering, Prototyping and DFM Engagement

We support your project from RFQ to rollout.

Our engineers provide free DFM feedback to improve results and reduce cost.

Workflow

- Submit drawing (STEP/DXF/PDF)

- Get quote + lead time in 24 hours

- Confirm die design (optional preview)

- Sample run + FAI/CMM report

- Approve and start production

- Track shipment via Prime portal

Lead time: Tooling 7–12 days | Production: 10–15 days

FAQs

Can I get stamping parts for my own design?

Yes. Just send your file—we accept PDF, STEP, IGES, DXF.

Do you offer progressive stamping?

Yes. For quantities 10k–1 million+ parts.

Can you help with design optimization?

Yes. We offer free DFM analysis with material, die, and tolerance suggestions.

What kind of parts can you stamp?

We do brackets, terminals, clips, springs, mounts, panels, covers, shields, rings.

Do you ship internationally?

Yes. We export to over 40 countries with full customs and CO support.

Conclusion & Call to Action

Custom stamping isn’t just an upgrade—it’s essential. It lowers cost, reduces downtime, and improves performance.

📧 Contact us now at [email protected]

🌐 Visit https://primecustomparts.com to get a free quote, DFM advice, or custom stamping support.

Let Prime help you stamp precision into every part.