TEMPLATE_START

How much do blacksmithing tools cost?

Many buyers hesitate because they don’t know the full cost of starting blacksmithing.

This article breaks down the price range for blacksmith tools, setup costs, and the business outlook for modern blacksmiths.

Knowing the cost helps avoid overspending—and plan better.

How much does blacksmith equipment cost?

Most new buyers or hobbyists don’t know what a realistic setup costs.

A basic blacksmithing setup can cost anywhere from $500 to $5,000, depending on quality and scale.

Cost varies based on equipment grade and usage

Entry-level blacksmithing tools are widely available online, but professional-grade tools can be expensive—especially forged anvils and industrial hammers. Many of Prime’s customers order forged blanks or pre-machined tools for cost-effective, high-volume kits.

| Tool | Entry-Level Price | Professional Price | Prime OEM Option |

|---|---|---|---|

| Anvil (100 lbs) | $150–$300 | $800–$1,200 | CNC-milled or cast |

| Forge (propane/coal) | $200–$500 | $1,000+ | Forge shell + burner kit |

| Hammer (cross-peen) | $25–$50 | $80–$120 | Forged, heat-treated head |

| Tongs (set of 3) | $50–$100 | $150+ | Welded or drop-forged |

| Vise (leg or bench) | $80–$200 | $300+ | Cast body + screw set |

At Prime, we serve tool brands, OEM training providers, and retailers looking to offer toolkits at competitive pricing—without sacrificing durability or quality.

Is blacksmithing a dying trade?

Some buyers worry that blacksmithing is no longer relevant in modern manufacturing.

Blacksmithing isn’t dying—it’s evolving into niche manufacturing, artisan metalwork, and industrial prototyping.

Demand is shifting—not disappearing

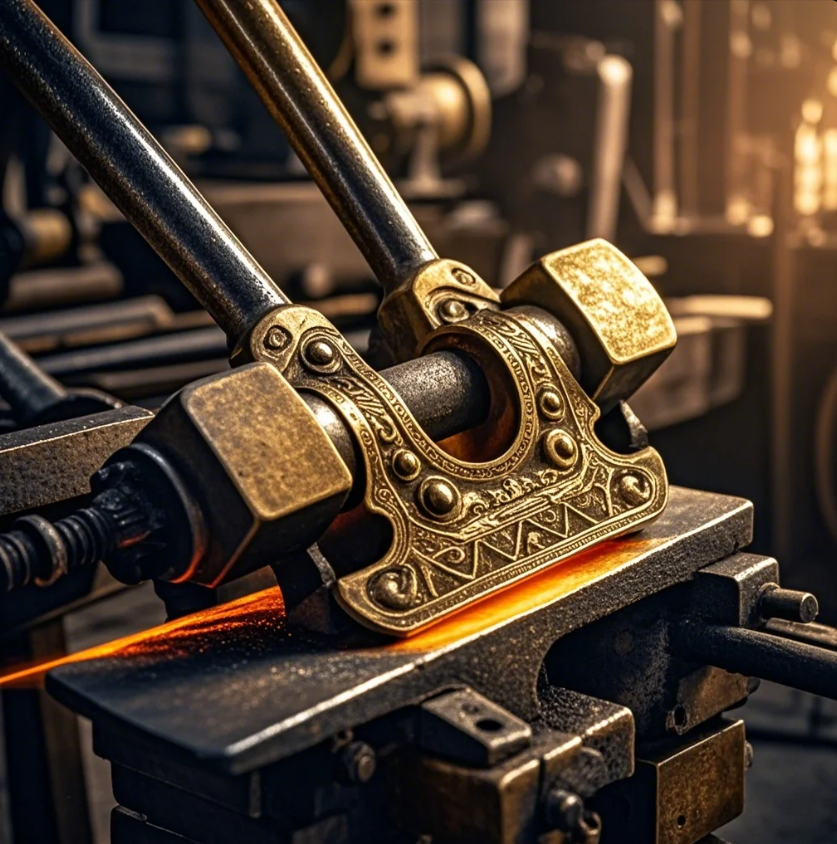

Today, blacksmithing combines tradition and innovation. In industrial settings, blacksmiths are toolmakers, prototype developers, and small-scale custom fabricators. In consumer markets, handmade blacksmith goods are highly valued.

Prime supports this evolution with ISO-certified forged parts for both traditional blacksmiths and modern fabricators. Many of our customers serve:

- Artisan blacksmiths (custom knives, tools, furniture)

- Industrial R&D (prototyping parts)

- Blacksmithing schools or DIY workshops

- Hardware and construction tool markets

Where modern blacksmithing thrives:

| Market Type | Growth Area |

|---|---|

| Artisan Crafts | Kitchen tools, jewelry, decor |

| Industrial Prototyping | Test tools, brackets, fixtures |

| Education | Training kits, entry-level tooling |

| Online Retail | DIY kits, custom tool sets |

Blacksmithing is now a value-driven business—and Prime enables brands to scale up product lines or test new markets fast.

What tools do you need for a blacksmith?

Clients often ask: “What are the minimum tools to get started?”

Every blacksmith needs a forge, anvil, hammer, and tongs to begin forging.

Core tools build the foundation for all projects

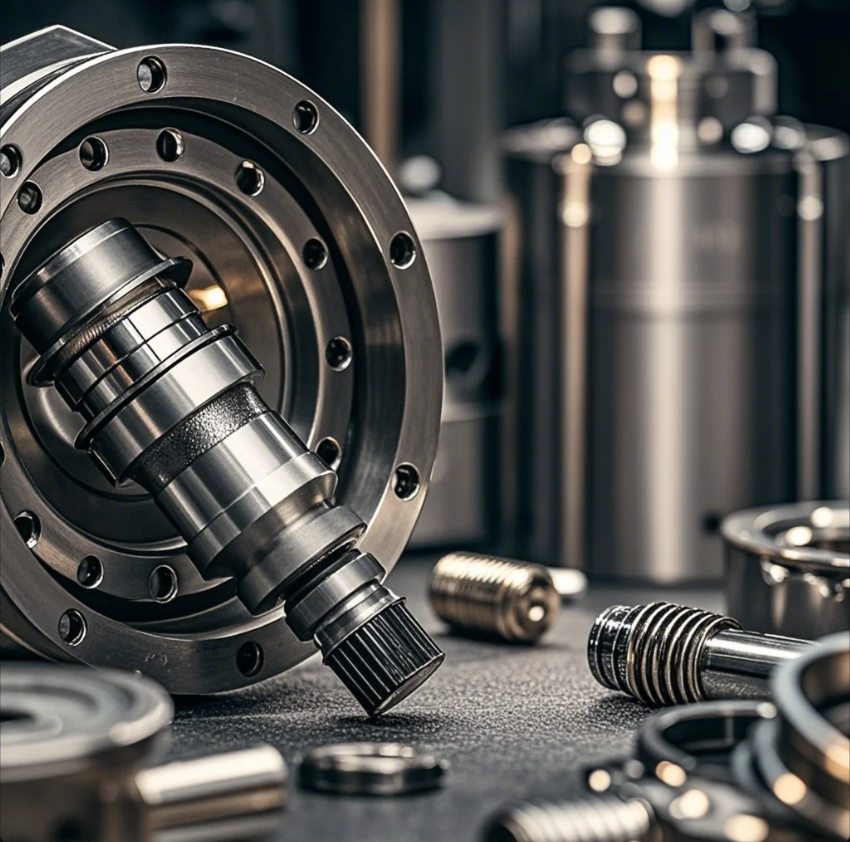

Whether you’re forging for industrial use or as a hobby, the same basic toolset applies. For example, a propane forge is easier and cleaner than a coal forge, while a forged anvil offers better bounce-back and longevity than cast iron.

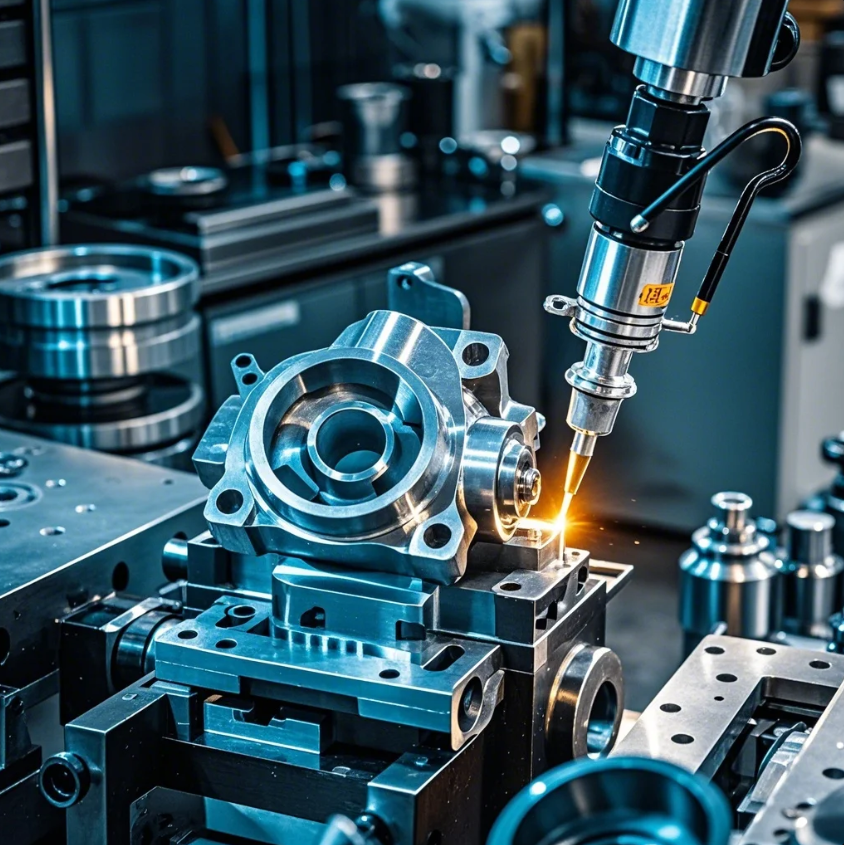

Prime supplies OEM forging equipment parts, such as forged hammer heads, cast vise bases, or CNC-finished anvil blocks—customized to brand requirements.

| Tool | Primary Function | Prime Product Type |

|---|---|---|

| Forge | Heats metal | Shells, burner kits, valves |

| Anvil | Shaping and forming surface | CNC, hardened edge options |

| Hammer | Impact for shaping | Drop-forged, heat-treated |

| Tongs | Holding heated metal | Mild steel or alloy claws |

| Vise | Clamping during cold work | Cast and machined body parts |

These tools can be bundled into starter kits or bulk orders for trade schools, hardware stores, or blacksmith training centers.

Do blacksmiths make good money?

Many potential buyers wonder if blacksmithing can be profitable.

Yes—blacksmiths can make good money, especially with a niche or industrial focus.

Profitability depends on product type, branding, and efficiency

While traditional blacksmithing may not be as common, modern blacksmiths succeed in high-value markets: custom knives, restoration, metal furniture, art, and precision tools. Industrial blacksmithing jobs also pay well, especially in repair and prototyping roles.

Prime supports OEM clients with parts that lower production costs while increasing product value. We also offer custom packaging and branding, which helps sellers increase retail margins.

Income potential by niche:

| Blacksmith Focus | Average Profit Potential |

|---|---|

| Custom knife making | $100–$500 per item |

| Tool forging (OEM) | $10–$40 per unit (bulk) |

| Furniture hardware | $50–$150 per piece |

| Teaching / demo services | $30–$100 per hour |

| Restoration / repair work | Project-based ($500–$2000+) |

Successful blacksmiths invest in high-quality forged components, clear branding, and reliable supply chains—exactly what Prime delivers to industrial buyers worldwide.

结论

Blacksmith tools vary in price, but smart planning and sourcing lead to higher profits and better efficiency.

At Prime, we help you build a profitable blacksmithing operation from the ground up. Whether you're sourcing forged hammer heads, starter toolkits, or ISO-certified components, our team ensures precision, fast delivery, and unbeatable pricing.

👉 Send us your inquiry now to receive a free quote, tool consultation, and custom sourcing plan. Let Prime be your forging supply partner—trusted by thousands worldwide.

TEMPLATE_END