Delays, rework, and scrap often come from mismatched machines1, wires, and gases.

Choose the welding process1 (GMAW/MIG, FCAW-G, FCAW-S, or pulsed MIG) based on environment and thickness; then select a wire classification2 (e.g., ER70S-6, E71T-1C/M, ER308L, ER4043/5356), diameter (0.8–1.2 mm / 0.030–0.045"), shielding gas (e.g., C25), and correct polarity. Verify WPS/WPQR and inspection before production.

I’ll keep this buyer-focused: practical specs1, trade-offs, and QA gates so you can send an RFQ2 confidently.

Understanding Different Types of Wire Welders?

Choosing the wrong machine1 wastes days and makes quality unstable2.

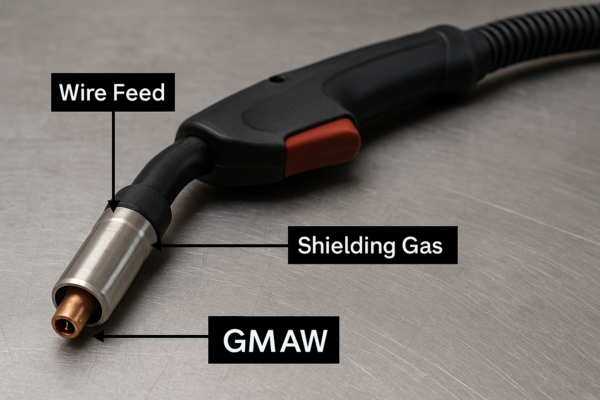

Wire welders fall into three buyer-relevant groups: GMAW/MIG (solid wire + gas)1, FCAW-G (flux-cored + gas)2, and FCAW-S (self-shielded, no gas). MIG thrives indoors; FCAW-S suits windy jobsites; FCAW-G delivers high deposition. Most solid/FCAW-G wires run DCEP; many FCAW-S wires run DCEN—set polarity correctly.

When I specify a welder, I begin with the work environment and the thickest joint. Indoors on mild steel, MIG/GMAW1 offers low spatter, easy training, and clean beads. Outdoors or in drafty bays, shielding gas can be unreliable; FCAW-S removes cylinder logistics and keeps productivity high. For thicker sections and all-position productivity, FCAW-G2 often wins on deposition rate, especially with 100% CO₂ or Ar/CO₂ mixes. If cosmetic quality matters on stainless or aluminum, pulsed MIG stabilizes the arc at lower heat input, reducing distortion and grinding.

Duty cycle matters. A 250–350 A class feeder with 200–300 mm (8–12") spools typically supports continuous welding on 3–10 mm plate without overheating. Spool capacity affects shift changeovers; match to your takt time. Finally, polarity is non-negotiable: most solid and gas-shielded flux-cored wires are DCEP; many self-shielded wires are DCEN. I lock these in the WPS and post a big “POLARITY” tag at the feeder to prevent porosity and erratic starts. For code work, align to AWS D1.11 (steel) and relevant filler specs (AWS A5.18/A5.9/A5.10) before you cut metal.

Practical checkpoints buyers should verify

- Process fit to site: MIG (shop), FCAW-G (high deposition)1, FCAW-S (outdoor/windy).

- Polarity matches the filler datasheet (DCEP vs DCEN).

- Duty cycle at planned amperage2; spool size supports shift length.

Quality & packaging notes buyers care about

- WPS/WPQR to code (e.g., AWS D1.11); maintain welder continuity logs2.

- Feeder calibration records and gas purity certificates3 when applicable.

- Export packaging: shock-tested crates, VCI, humidity cards, and spare liners.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Process | GMAW (solid wire) | FCAW-G / FCAW-S | FCAW can deposit faster; FCAW-S avoids gas logistics outdoors.1 |

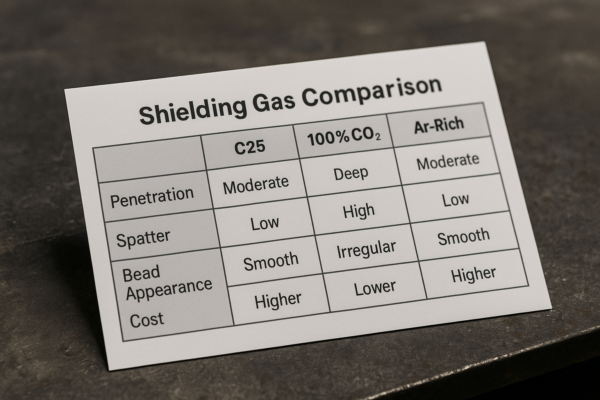

| Gas | C25 (75/25 Ar/CO₂) | 100% CO₂ | CO₂ is cheaper; C25 reduces spatter/cleanup time.2 |

| Power Source | Conventional CV | Pulsed-capable | Pulsed improves arc control on thin/stainless/Al; higher machine cost. |

| Polarity | DCEP | DCEN | Wrong polarity causes porosity/fusion issues; verify at setup. |

| Duty Cycle | 200 A class | 350 A class | Higher class supports thicker joints/longer arcs; increased capex. |

| Spool Size | 200 mm (8") | 300 mm (12") | Larger spools reduce changeovers; consider crane/handler access. |

Upload your drawing to get 24-hour DFM advice1 and a quote2.

Choosing the Right Wire for Welding?

Wrong wire chemistry1 or diameter multiplies2 rework and downtime.

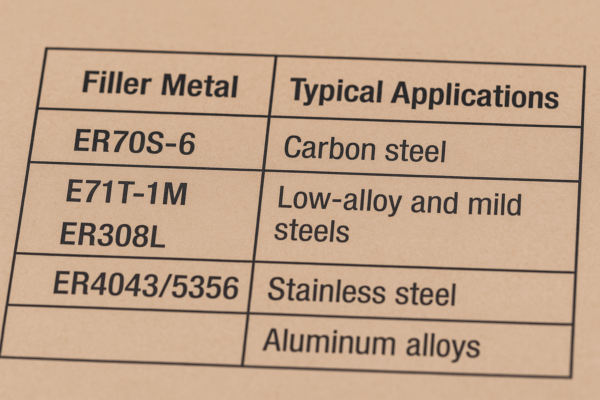

Pick wire by base metal, strength, position, and environment. Carbon steel: ER70S-6 (MIG)1 or E71T-1C/M (FCAW-G). Stainless 304/304L: ER308L2. Aluminum: ER4043 (ease) or ER5356 (strength/forming). Choose 0.8/0.9/1.2 mm (0.030/0.035/0.045") diameter; pair ER70S-6 with C25 and confirm polarity.

I start with the classification and code callouts. ER70S-61 (AWS A5.18) is forgiving on mill scale, stable on CO₂ or C25, and excellent for general fabrication. E71T-1C/M (AWS A5.20) gives higher deposition in flat/horizontal positions; “C” indicates 100% CO₂, “M” indicates Ar/CO₂ mixes. For stainless 304/304L, ER308L2 (AWS A5.9) keeps carbon ≤0.03% to resist sensitization in heat-affected zones. For aluminum, ER4043 wets easily and resists hot cracking; ER5356 offers higher as-welded strength and better post-forming—common when parts need bending after welding (AWS A5.10).

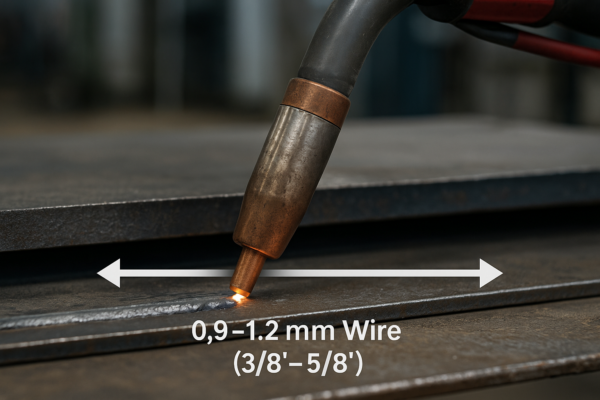

Diameter drives penetration and travel speed. 0.8 mm (0.030")1 is my choice for thin sheet or filigree brackets; 0.9 mm (0.035") suits general fab; 1.2 mm (0.045") boosts deposition on thicker joints. Gas selection matters: for mild steel MIG, C25 (75% Ar / 25% CO₂)2 balances cost, arc stability, and low spatter; 100% CO₂ cuts gas cost but increases cleanup. Always align wire chemistry and mechanicals to your WPS, then record exact amps/volts/WFS in a PQR so your floor team isn’t guessing later.

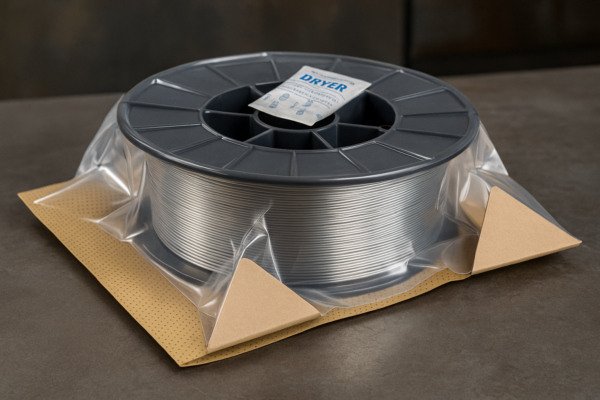

For supply chain control, I require MTC/heat certs1 and lot tracking for each spool. Spools should ship vacuum-sealed with desiccant and VCI; I also ask suppliers for “no-telescoping” wind specs to prevent feed instability near the end of a spool.

Practical checkpoints buyers should verify

- Wire classification1 matches base metal and service (ER70S-6, ER308L, ER4043/5356, E71T-1C/M).

- Diameter fits thickness and joint design (0.030/0.035/0.045").

- Gas plan2 confirmed with monthly consumption and cylinder logistics.

Quality & packaging notes buyers care about

- Request MTCs, lot traceability1, and shelf-life data per spool.

- Seal spools with desiccant/VCI; specify flanged, “no-telescoping” wind.

- Demand FAI/CMM2 on welded samples and a weld map with amps/volts/WFS.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Material/Grade1 | ER70S-6 (solid) | E71T-1C/M (flux-cored) | Solid is cheaper; flux-cored deposits faster, shortening cycle time. |

| Stainless Choice | ER308L | ER309L/ER316L | Dissimilar or corrosive environments may need 309L/316L; higher consumable cost. |

| Aluminum Choice | ER4043 | ER5356 | 4043 = crack resistance; 5356 = higher strength/forming; different color after anodize. |

| Wire Diameter2 | 0.8 mm (0.030") | 1.2 mm (0.045") | Small improves control; large increases deposition rate. |

| Gas | C25 | CO₂ or Ar-rich | C25 reduces spatter; pure CO₂ reduces gas cost; Ar-rich enables spray/pulsed. |

| Testing/Reports | VT only | VT + macro/bend + CMM | Adds 1–3 days but de-risks full-lot production. |

Upload your drawing to get 24-hour DFM advice1 and a quote2.

Common Wire Welding Techniques Explained?

Technique drift1 kills repeatability and margins2.

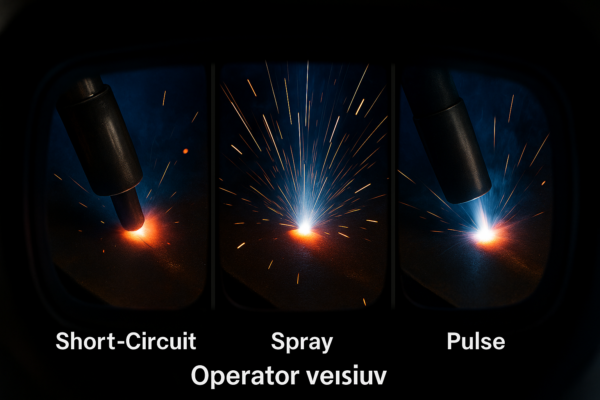

Control contact tip-to-work distance1 (10–15 mm / 3/8–5/8"), keep consistent travel angle, and select the right transfer mode: short-circuit for thin/out-of-position, spray for thicker sections, and pulsed to manage heat on stainless/aluminum. Follow the filler datasheet2 for polarity and settings to avoid porosity.

I tune technique to joint and distortion risk. Short-circuit (GMAW-S)1 gives low heat input and good gap-bridging on thin sheet, but it can under-penetrate on thick plate if travel speed is too high. Spray transfer2 (argon-rich gas, higher current) yields smooth beads and deep penetration—great for thick sections and flat/horizontal positions. Pulsed spray alternates peak/background current to stabilize metal transfer; it’s my go-to on stainless and aluminum when cosmetic finish and low distortion matter.

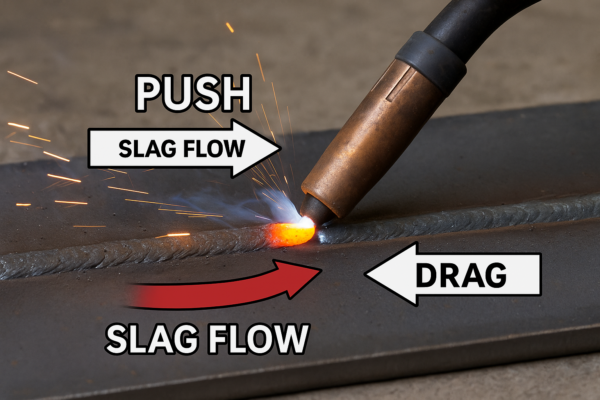

Torch angle is simple: a slight push (5–15°) on MIG thin-gauge helps wash toes; a drag angle1 often suits FCAW-S to keep slag behind the puddle. Keep CTWD2 consistent; too long increases spatter and undercut, too short overheats the tip. For 0.9–1.2 mm (0.035–0.045") wires, I standardize at 10–15 mm (3/8–5/8") stick-out unless the WPS dictates otherwise.

Before scaling, freeze parameters in your WPS and qualify with macro etch/bend tests as needed by code (e.g., AWS D1.11 for steel). Maintain fume controls and PPE; stainless welding can generate hexavalent chromium2—consult NIOSH/OSHA guidance. Photograph first-article bead profiles, record amps/volts/WFS, and add visual cues for operators (arc sound, puddle wetting). These habits protect quality when shifts rotate.

Practical checkpoints buyers should verify

- Transfer mode set to joint need1: short-circuit (thin/out-of-position), spray (thick), pulsed (heat-sensitive).

- Stick-out, travel angle, and torch movement documented with photos in the WPS.

- Polarity posted at the feeder2; run macro etch on first articles.

Quality & packaging notes buyers care about

- WPS/WPQR to AWS; consider ISO 38341 for welding quality management.

- Fume controls/PPE per NIOSH and OSHA2; special attention for stainless (Cr(VI)).

- Ship with foam-in-place, corner guards, humidity indicators; include WPS printouts.

| Factor | Option A | Option B | What it means for cost/lead time |

|---|---|---|---|

| Transfer | Short-circuit | Spray/Pulsed | Short-circuit reduces distortion; spray/pulsed boosts speed on thicker stock. |

| Angle | Push (5–15°) | Drag | Push improves fusion on thin; drag helps with slag control in FCAW-S. |

| CTWD | 10 mm (3/8") | 15 mm (5/8") | Shorter stabilizes arc but heats the tip; longer risks spatter/undercut. |

| Travel Speed1 | Slower | Faster | Slower improves fusion; faster increases throughput—watch heat input. |

| Surface Finish2 | CO₂-rich mixes | Ar-rich/pulsed | Argon-rich and pulsed reduce spatter and grinding time. |

| Testing/Reports | VT | VT + macro/bend + CMM | Confirms penetration and dimensions before full-lot release. |

Upload your drawing to get 24-hour DFM advice1 and a quote2.

Why partner with Prime? I write from a buyer’s seat and run manufacturing inside an ISO-certified factory1 (Prime, China; founded 1993) with 10 production lines2. We produce stamping parts, CNC parts, casting parts, screws, plastic parts, and welded assemblies for global B2B buyers. Expect fast DFM, fixture advice, WPS alignment, and inspection packs (FAI/CMM). Packaging is robust: VCI + foam + drop-tested crates. Upload your drawing—get practical weld parameters and a clean quote in 24 hours.

Conclusion

Decide process, wire, gas, and technique early, lock a code-compliant WPS, and protect QA and packaging—send your drawing for a fast quote now.

-

Learn about the significance of ISO certification and how it ensures quality and reliability in manufacturing. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore how multiple production lines can enhance efficiency and output in manufacturing processes. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring gas purity certificates can enhance your knowledge of welding safety and quality assurance. ↩