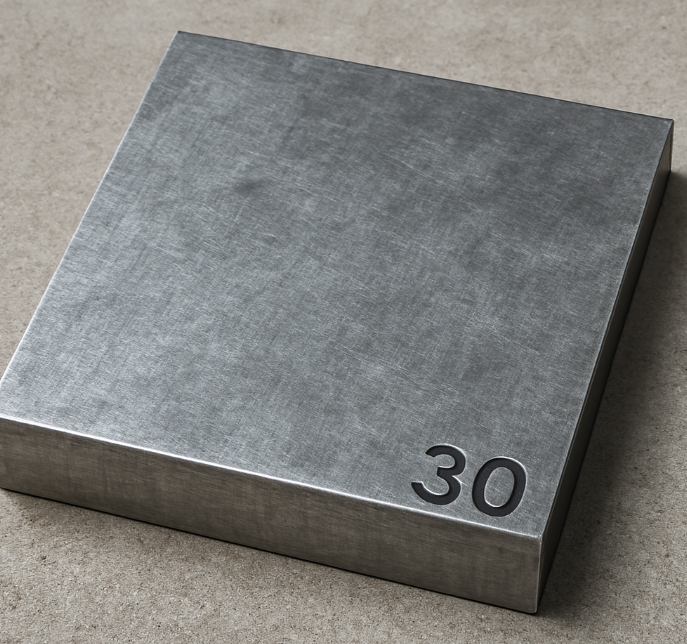

How Thick Is 30 Gauge Sheet Metal?

When ordering sheet metal, gauge numbers can be confusing – the higher the gauge, the thinner the material. 30 gauge represents one of the thinnest standard sheet metal sizes available commercially.

Snippet paragraph: 30 gauge sheet metal thickness measures 0.0120 inches (0.305 mm) for steel and 0.0100 inches (0.254 mm) for aluminum based on standard gauge measurements, with minor variations for specific alloys.

Understanding gauge measurements helps you select the right material for your project. Let’s examine 30 gauge more closely.

LOOP_START

How Does 30 Gauge Compare to Other Common Gauges?

Gauge numbering works inversely – smaller numbers indicate thicker materials. Here’s how 30 gauge fits in the spectrum.

Snippet paragraph: 30 gauge metal (0.012") is nearly half as thick as 26 gauge (0.0179") and three times thinner than 20 gauge (0.036"). It’s similar to 6 sheets of standard printer paper stacked together.

Gauge Thickness Comparison

Steel Sheet Thickness Examples

- 16 gauge: 0.0598" (1.52mm) – Heavy duty use

- 22 gauge: 0.0299" (0.76mm) – HVAC ductwork

- 30 gauge: 0.0120" (0.30mm) – Lightweight applications

Common Applications by Gauge

| Gauge | Inches | mm | Typical Uses |

|---|---|---|---|

| 10 | 0.1345 | 3.416 | Truck frames |

| 18 | 0.0478 | 1.214 | Appliances |

| 24 | 0.0239 | 0.607 | Roof flashing |

| 30 | 0.0120 | 0.305 | Model making, crafts |

Material Differences

- Galvanized steel: 0.0120"

- Stainless steel: 0.0105"-0.0125"

- Aluminum: 0.0100"

- Copper: 0.0090"

LOOP_END

LOOP_START

What Can You Make With 30 Gauge Sheet Metal?

This ultra-thin material serves specialized purposes where flexibility and light weight matter more than strength.

Snippet paragraph: 30 gauge metal works best for decorative elements, thermal shielding, model building, and sound dampening where structural strength isn’t required. It’s too thin for most load-bearing applications.

Practical Applications

Industrial Uses

- EMI/RFI shielding layers

- Surface protection during transport

- Insulation backing material

- Washer and shim stock

Creative/Craft Uses

- Metal lettering and signage

- Costume and prop building

- Scenery for model railroads

- Jewelry components

Material Limitations

| Feature | 30 Gauge Capability | Notes |

|---|---|---|

| Bend Radius | 0.030" minimum | Sharp bends cause cracking |

| Weight Capacity | <1 lb per square foot | Not structural |

| Cut Method | Tin snips or laser | Not shearable |

| Fastening | Adhesives only | Too thin for screws |

LOOP_END

LOOP_START

What Are the Challenges of Working With 30 Gauge Metal?

Handling this thin material requires different techniques than standard sheet metal work.

Snippet paragraph: The primary challenges with 30 gauge include tearing during handling (requires backing material), oil canning during forming (needs tension control), and difficulty achieving clean cuts (laser preferred over mechanical).

Working Considerations

Special Handling Requirements

-

Cutting Methods

- Laser: Cleanest edges

- Nibblers: Minimal distortion

- Avoid: Shearing causes curling

-

Forming Challenges

- Requires radiused dies

- Multiple shallow bends better than one sharp bend

- Needs support during forming

-

Flatness Control

- Stores best on flat pallets

- Prone to memory effect – hard to flatten

- Often requires adhesive backing

Tooling Recommendations

| Operation | Standard Gauge Tool | 30 Gauge Adjustment |

|---|---|---|

| Cutting | Power shear | Laser/waterjet |

| Bending | Standard brake | Polished radius dies |

| Drilling | Twist drill | Step drill bits |

| Finishing | Flap wheel | Fine abrasive pads |

LOOP_END

Conclusion

30 gauge sheet metal (0.012") serves specialized lightweight applications but requires careful handling due to its extreme thinness and flexibility.