How to Choose a Certified Custom CNC Parts Supplier? 🚀

Problem: You need CNC parts fast. But you fear poor quality, delays, or bad communication.

Agitate: This hurts productivity and product quality.

Solve: This guide shows how to pick a certified CNC supplier you can trust.

Snippet paragraph:

✔️ ISO 9001/AS9100 ensures consistent quality.

✔️ ±0.01 mm CNC tolerance reduces product errors.

✔️ Learn real examples and FAQs to simplify decision-making.

✔️ Get a trusted supplier for fast, precise, and safe delivery.

ISO 9001/AS9100 Certification: Why It Matters?

Certified CNC suppliers follow strict standards that reduce quality issues. ISO 9001 ensures quality systems and process control. AS9100 adds requirements for aerospace and high-risk applications.

| Certification | Focus | Industries | Key Benefit |

|---|---|---|---|

| ISO 9001 | General Quality Management | All manufacturing sectors | Stable processes, less variation |

| AS9100 | Aerospace Quality Standard | Aerospace, Defense | Full traceability, risk control |

Learn more on ISO.org

SAE AS9100 Details

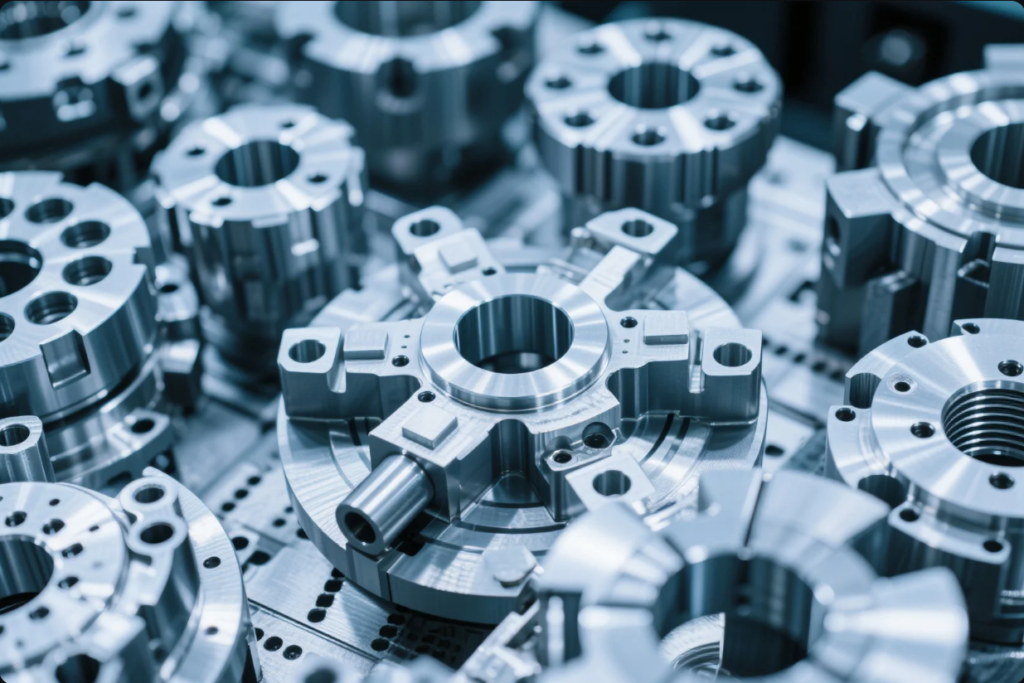

CNC Tolerance ±0.01 mm: Achieving Precision?

When your parts must fit precisely, you need tight tolerances. ±0.01 mm is a critical standard in many industries. Make sure your supplier has calibrated equipment, CMM inspections, and environmental control.

| Feature | Nominal Value | Measured Value | Deviation |

|---|---|---|---|

| Hole Diameter | 5.000 mm | 5.003 mm | +0.003 mm |

| Slot Width | 2.000 mm | 1.998 mm | –0.002 mm |

| Edge Flatness | – | Within spec | Pass |

Guide to Tolerance

Thermal Expansion in Metals

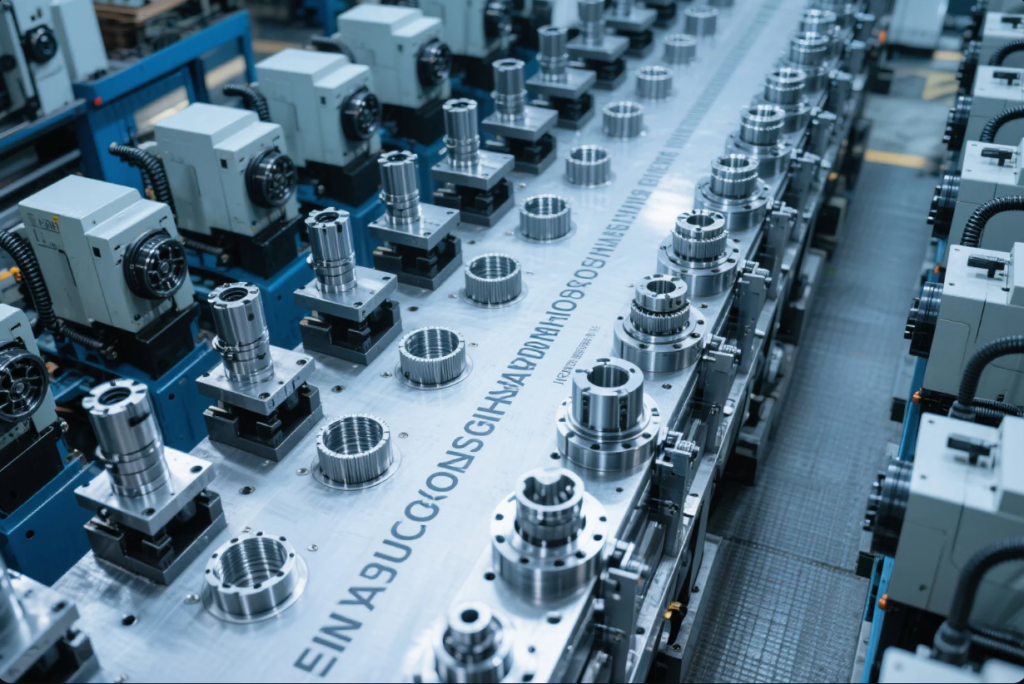

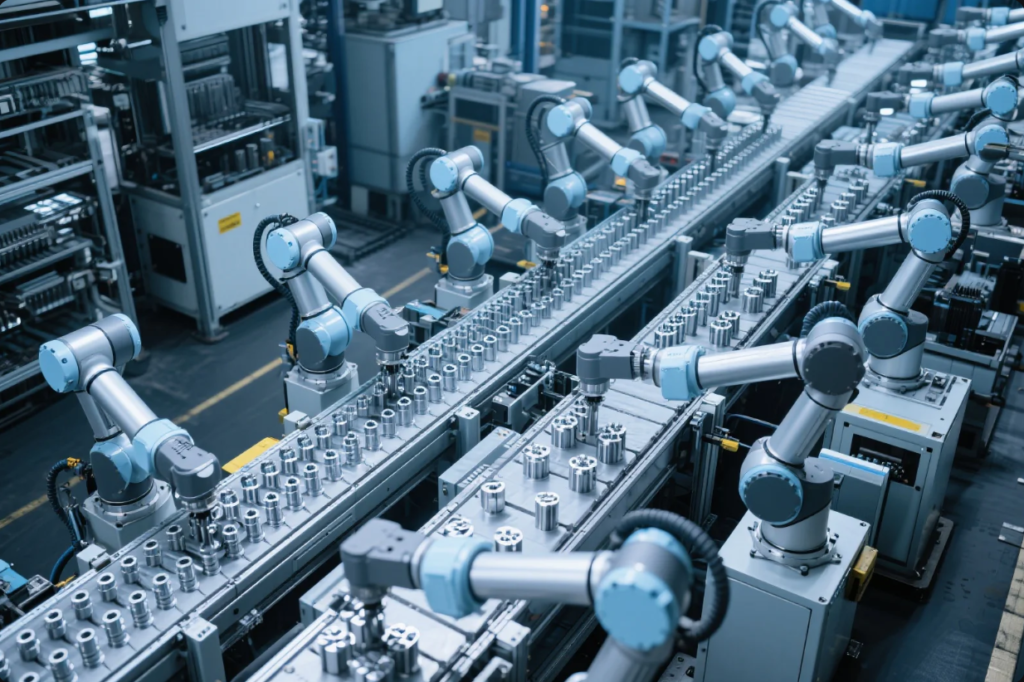

Evaluating Multi‑Axis Machining Capabilities?

Multi-axis machining enables production of complex shapes in one setup. It reduces errors, improves surface finish, and lowers cost over time.

| CNC Type | Axes Controlled | Typical Applications |

|---|---|---|

| 3-Axis | X, Y, Z | Flat, prismatic parts |

| 4-Axis | X, Y, Z + A (rotation) | Cylindrical parts, holes at angles |

| 5-Axis | X, Y, Z + A, B | Complex contours, aerospace parts |

Modern Machine Shop – 5-Axis Advantages

Case Study: Fast Quoting & Prototyping Workflow?

A U.S. client needed urgent robotic parts. Here’s how Prime delivered in just 5 working days:

| Step | Time Taken | Outcome |

|---|---|---|

| CAD Review | < 1 day | Feasibility confirmed |

| Quotation Issued | Same day | Competitive pricing |

| Prototype Machined | 5 days | High-precision sample shipped |

| QC Inspection | 1 day | Full CMM report provided |

Autodesk Fusion 360

Mastercam Software

Additional Considerations When Choosing CNC Suppliers

Beyond equipment, look for:

- On-time delivery capability

- Packaging customization

- Transparent communication

- Multi-language support

- Experience with global clients

Check supplier ratings:

FAQs

Q1: What file formats are accepted? — STEP, IGES, DWG

Q2: Can I customize packaging? — Yes, foam, barcode, rust-proofing available

Q3: Lead time for 500 pcs? — Typically 10–15 working days

Q4: Are prototypes available before mass production? — Absolutely

Q5: What industries do you serve? — Aerospace, automotive, robotics, energy

Q6: Is my design protected? — Yes, NDA and secure storage guaranteed

Conclusion

Choosing a CNC supplier isn’t just about cost—it’s about consistency, capability, and communication. Prime offers all three.

📧 Contact us today for a free quote and consultation:

Email: [email protected]

Website: https://primecustomparts.com

Get your parts made right, on time, and hassle-free.