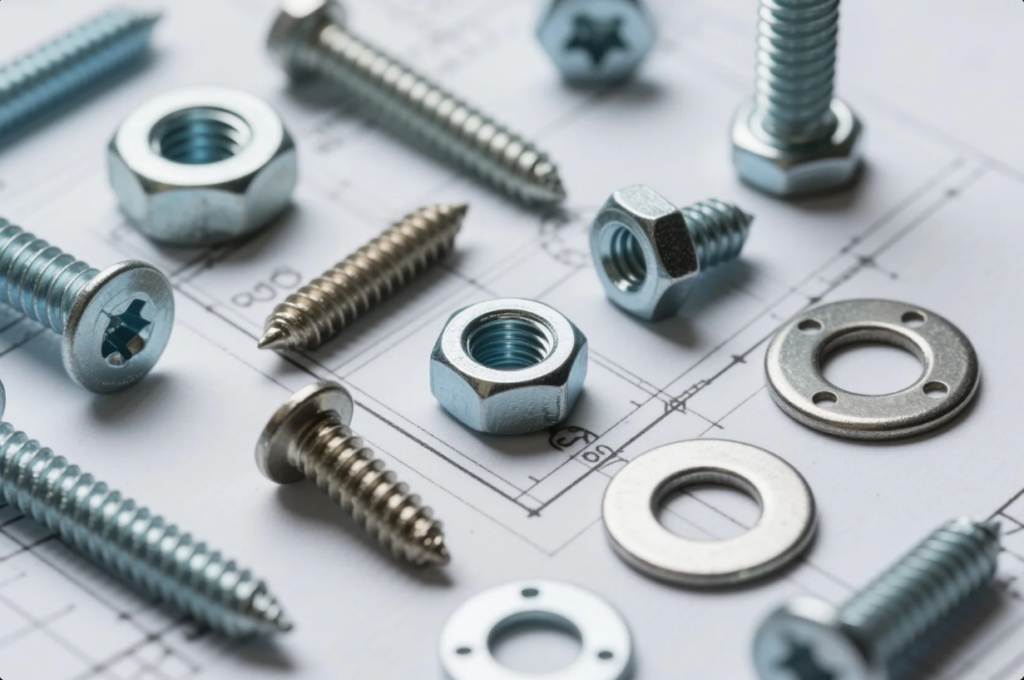

How to Choose the Best Material for Metal Fasteners?

Struggling to select the right fastener material?

Choosing the best material for metal fasteners ensures long-term performance. Material choice impacts corrosion resistance, strength, and cost. Understand key factors to make informed sourcing decisions.

Your fastener’s material can make or break your project. Get the facts before you buy.

Introduction

Choosing the right fastener material is not just about strength or price. It’s about ensuring your product performs over time. Whether you manufacture machines, electronic devices, or construction structures—material matters. At Prime, we’ve supported thousands of global clients with custom fasteners optimized for strength, corrosion resistance, and price. Based on 20+ years of experience, here’s how we help buyers choose wisely.

Key industry resources:

Carbon Steel vs Stainless Steel: Strength & Corrosion

Stainless steel resists corrosion, but carbon steel offers higher tensile strength. Choosing depends on the environment and load.

Carbon steel fasteners are strong and cost-effective. Stainless steel works best for wet or corrosive conditions. Each has trade-offs in strength and corrosion resistance.

Additional guides:

Understanding the Differences

| Material | Corrosion Resistance | Strength Level | Typical Use Cases |

|---|---|---|---|

| Carbon Steel | Low | High | Machinery, automotive |

| Stainless Steel | High | Medium | Marine, outdoor fixtures |

Steel overviews:

Real-world comparison:

When to Use Alloy Steel or Aluminum Fasteners

Alloy steel gives top strength. Aluminum fasteners are lightweight and resist oxidation.

Alloy steel fasteners hold up under extreme pressure. Aluminum fasteners are best for low-load and non-magnetic uses.

Materials info:

Matching Material to Application

| Material | Strength | Weight | Corrosion Resistance | Ideal For |

|---|---|---|---|---|

| Alloy Steel | Very High | Heavy | Moderate | Heavy equipment, high stress |

| Aluminum | Low | Light | High | Electronics, transport |

More reading:

Copper, Brass & Zinc Alloy: Pros & Cons

Copper alloys resist corrosion but are costly. Brass looks good but lacks strength. Zinc alloys are affordable but limited.

Copper, brass, and zinc alloys suit niche needs. Balance aesthetics, cost, and conductivity when picking among them.

Resources:

- Copper.org properties

- Brass alloy data (MatWeb)

- Zamak/Zinc alloy info (International Zinc Association)

Weighing Your Options

| Material | Corrosion Resistance | Conductivity | Cost | Common Uses |

|---|---|---|---|---|

| Copper | Excellent | Excellent | High | Electrical terminals, roofing |

| Brass | Good | Good | Medium | Decorative fixtures, plumbing |

| Zinc Alloy | Moderate | Low | Low | Consumer goods, light-duty fasteners |

Case studies:

- Grounding copper fasteners benefits (ESCO)

- Brass decorative hardware (Herman Miller)

- Zinc alloy die casting benefits (Dynacast)

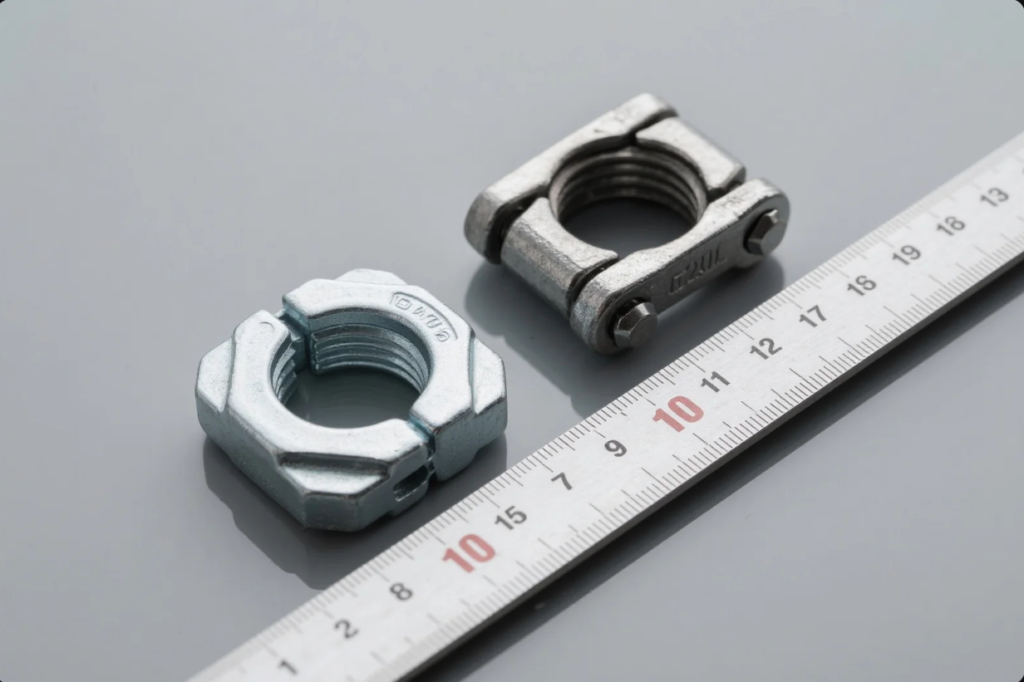

Surface Treatments That Enhance Durability

Treatments like galvanizing or black oxide prevent rust. Coatings boost lifespan and lower maintenance.

Surface treatments protect the fastener and improve looks. Choose based on operating conditions and visual needs.

Industry links:

- Surface Engineering Association

- Galvanizers Association UK

- Black oxide treatment guide

- Phosphate coatings overview (Rockwell Automation)

- Nickel plating benefits (Nickel Institute)

Comparing Common Treatments

| Treatment | Benefit | Ideal Use Case |

|---|---|---|

| Zinc Plating | Basic Corrosion Resistance | Indoor appliances |

| Hot-Dip Galvanize | Heavy-Duty Outdoor Protection | Steel structures, poles |

| Black Oxide | Aesthetic + Mild Rust Resistance | Tools, interior hardware |

| Phosphate | Improves Paint Adhesion | Painted machinery or furniture |

| Nickel Plating | Decorative + Conductivity | Electronics, marine hardware |

FAQs

1. What’s the most corrosion-resistant fastener material?

Stainless steel and copper offer the highest corrosion resistance. For saltwater exposure, choose 316 stainless or tin-plated copper.

2. Are aluminum fasteners strong enough for structural loads?

Usually not. Aluminum is lightweight and corrosion-resistant but lacks the strength of alloy steel or carbon steel.

3. Can I request custom surface treatment on my fasteners?

Yes. At Prime, we provide zinc plating, hot-dip galvanizing, black oxide, phosphate, and nickel coating per customer specs.

4. How can I verify fastener quality before shipping?

We offer dimensional inspections, material certificates, ISO 9001 documentation, and salt-spray corrosion test results on request.

5. What’s the minimum order quantity for custom fasteners?

MOQ varies by material and size. Contact us for a personalized quote. Small trial orders are accepted for new customers.

Conclusion & Contact

Choose the right fastener material to ensure strength, cost-efficiency, and reliability. Whether your focus is weight, appearance, or corrosion, we tailor the perfect fastener solution.

📩 Contact Prime today for a free consultation, fast quote, and tailored solution for your application.

🌐 Website: https://primecustomparts.com

✉️ Email: [email protected]

Let’s build your success—one fastener at a time.