How to Choose the Best Metal Custom CNC Parts: What Should You Consider?

Many buyers struggle with poor quality1, late shipments, and confusing choices for CNC parts2. You may have faced these headaches too. The good news is, you can avoid them with the right approach.

Custom CNC parts1 enable high precision and reliable performance across industries. Knowing the differences between turning, milling, and EDM2, and selecting the right supplier, prevents costly mistakes and wasted time. This guide will help you choose the best CNC parts for your project, with real insights and actionable advice.

Keep reading to learn how to make the right CNC sourcing decisions1. This article will cover technical differences, supplier evaluation2, industry applications, and practical sourcing tips that you can use right away.

What Are Custom CNC Parts? How Are Turning, Milling, Grinding, and EDM Different?

Many buyers find it hard to distinguish between CNC machining methods1. This confusion can lead to unnecessary costs or quality issues. I used to wonder which process was best for each part, especially when drawings had tight tolerances2 or complex shapes.

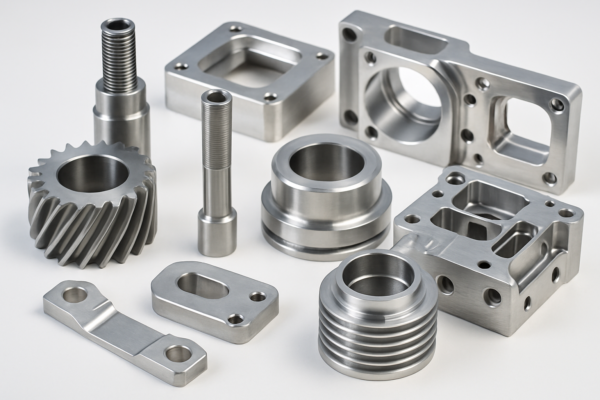

Custom CNC parts1 are manufactured to precise specifications using methods such as turning, milling, grinding, and EDM2. Each method has its advantages, limitations, and optimal uses in industrial manufacturing.

Understanding Key CNC Processes

- Turning1: The workpiece spins while a fixed cutting tool shapes it. Ideal for cylindrical components like shafts and bushings.

- Milling: The cutting tool moves across a stationary workpiece to form complex 3D shapes. Great for brackets, housings, and mold components.

- Grinding: Abrasive wheels provide extremely fine finishes and precise tolerances, especially for hardened materials.

- EDM (Electrical Discharge Machining)2: Uses electrical sparks to cut hard or intricate shapes, suitable for very tough materials.

| Process | Best For | Typical Tolerance | Surface Finish | Relative Cost | Example Parts |

|---|---|---|---|---|---|

| Turning | Cylindrical parts1 | ±0.01mm | Good | Low | Shafts, bushings, rings |

| Milling | Complex 3D shapes | ±0.02mm | Good | Medium | Housings, brackets, plates |

| Grinding | Surface finish, hard parts | ±0.005mm | Excellent | Higher | Gear teeth, precision dies |

| EDM | Intricate, hard materials2 | ±0.005mm | Excellent | Highest | Injection molds, turbine blades |

I learned through project work that choosing the right process is critical. If you use turning for a rectangular block1, you’ll waste time and money. If you select EDM2 for a simple shaft, the cost will be much higher with no added value.

Application Scenarios: Where Are Precision CNC Parts Used in Automotive, Aviation, Medical, and Robotics?

Precision is not optional in industries such as automotive, aviation, medical, and robotics. I have seen clients lose contracts over a single defective lot of fasteners1 or brackets. These industries require components that fit and function perfectly2, every time.

Precision CNC machining1 delivers quality parts for critical applications. Automotive, aerospace, medical, and robotics fields depend on strict tolerances2 and traceability.

Industry-Specific Requirements

- Automotive: Needs high volume, strong materials, and repeatable parts for safety-critical systems.

- Aviation: Demands extreme precision and lightweight components for safety and fuel efficiency.

- Medical: Requires flawless, biocompatible parts1—surgical tools and implants—with top-level cleanliness and documentation.

- Robotics: Relies on miniaturized, custom CNC parts2 that must meet high precision and repeatability standards.

| Industry | Key CNC Parts | Tolerance | Quality Focus | Example Application |

|---|---|---|---|---|

| Automotive | Gears, brackets, steering parts | ±0.01mm | High volume, safety | ABS mounts, transmission cases |

| Aviation | Turbine blades, fasteners | ±0.005mm | Traceability, reliability | Engine brackets, control levers |

| Medical | Surgical tools, implants | ±0.002mm | Biocompatibility, hygiene | Bone screws, surgical scissors |

| Robotics | Shafts, gears, housings | ±0.01mm | Miniaturization, accuracy | Joint modules, gripper components |

When I helped a US robotics firm, they insisted on supplier transparency1 and traceable documentation2. By providing full QC reports and ISO certificates from Prime, I won their long-term business.

How to Select ISO Certified CNC Parts Suppliers, Improve Quality Control, and Delivery Efficiency?

Choosing the right CNC parts supplier1 is not just about price. Reliability, communication, and quality control2 are what keep your project on track. I have worked with suppliers who failed to communicate or delivered late—these issues led to missed selling seasons and financial loss.

ISO certification1 provides confidence in quality systems. Top suppliers offer transparent QC2, clear packaging, traceable shipments, and rapid communication.

Supplier Selection Checklist

- Check ISO Certification1: Request copies and verify authenticity.

- Review Supplier Experience: Ask for case studies and previous industry experience.

- Factory Audit2: Visit in person or request a video tour.

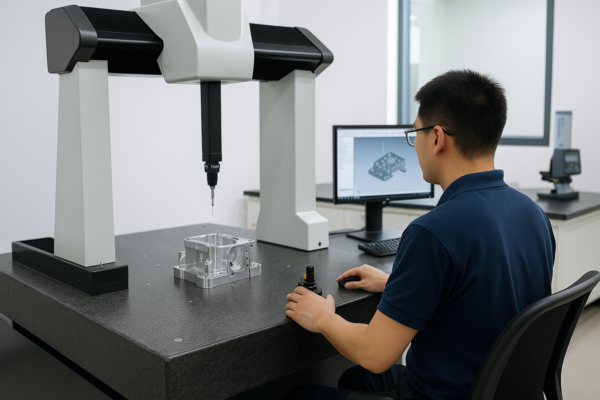

- Sample Inspection: Ask for sample parts, CMM reports, and full measurement data.

- Packaging Standards: Insist on detailed, export-grade packaging.

- Delivery Records: Check on-time delivery rates, request client references.

- QC Documentation: Demand full inspection records, with each shipment.

| Criteria | Reason | Best Practice |

|---|---|---|

| ISO Certification1 | Trust and traceability | Verified ISO 9001 |

| Experience | Application expertise | Industry references |

| QC Documentation2 | Prevents disputes | Full test reports |

| Packaging | Safe delivery | Export grade packing |

| Communication | Faster issue resolution | Real-time updates |

| Logistics | Meet customer deadlines | Reliable partners |

I always insist on dealing with suppliers who meet ISO standards1 and provide transparent documentation. At Prime, our production process includes 100% inspection2 before shipment, strict barcode traceability, and export-ready packaging.

Cost vs. Efficiency: Turning, Milling, and Laser Cutting – How to Make the Right Choice?

Sourcing managers must often balance cost, lead time1, and part complexity. The wrong process can drive up costs or cause project delays. I have learned to compare processes by cost efficiency2, speed, and part geometry.

Turning is cost-effective for simple, round parts1. Milling handles 3D shapes and intricate features. Laser cutting offers speed for flat sheets and prototyping2. Each method has its place in your sourcing strategy.

Practical Comparison of CNC Processes

| Process | Part Geometry | Setup Speed | Production Rate1 | Cost per Unit2 | Sample Application |

|---|---|---|---|---|---|

| Turning | Cylindrical | Low | High | Low | Shafts, pins, spacers |

| Milling | 3D, complex | Medium | Medium | Medium | Flanges, brackets, housings |

| Laser Cutting | Flat, 2D | Very Low | Very High | Low/Medium | Covers, plates, quick prototypes |

When I quoted 1,000 custom round bushings for a US customer, turning was the clear winner—fast and affordable. For a batch of custom brackets with holes and slots, CNC milling1 made sense. When a client needed 100 steel cover plates for rapid prototyping, laser cutting2 delivered parts in days, not weeks.

Balancing Cost, Speed, and Quality

It is important to discuss your project’s priorities with the supplier. Ask about volume discounts1, standard tolerances, and possible cost-saving adjustments. At Prime, we always provide a full process analysis2, suggesting the best match for your budget and lead time.

| Decision Factor | Turning | Milling | Laser Cutting |

|---|---|---|---|

| Geometry | Simple round | Complex 3D | Flat 2D |

| Best for | High volume | Prototyping, Low-Med Volume1 | Prototyping, Fast Delivery2 |

| Cost | Lowest | Moderate | Competitive |

| Lead Time | Short | Medium | Fastest |

| Example Industry | Automotive | Aerospace, Robotics | Robotics, Medical |

Case Study

Last year, I sourced thousands of custom spacers1 for a client’s automation line. By switching from milling to turning, we cut costs by 35%2 and shaved two weeks off delivery time.

More Real-World Insights: Customization, Communication, and Packaging

Effective communication1 and packaging2 can make or break your project. Many buyers overlook these factors, resulting in shipment damage or production delays. I have seen costly returns due to insufficient packaging2 or unclear communication.

- Customization: Ask for custom logos1, labeling, and barcoding. This ensures easy identification and traceability.

- Communication: Use clear drawings, tolerance tables, and 3D models to avoid misunderstandings.

- Packaging: Specify export-grade cartons2, foam inserts, and weatherproof wrapping for fragile or high-value CNC parts.

At Prime, we supply detailed photo documentation1 before shipment, offer custom labeling2, and ensure every export carton meets international standards.

FAQS

Q1: What is the minimum order quantity (MOQ)1 for custom CNC parts at Prime?

A: Our typical MOQ is 100 pieces per item, but we support samples for testing. Contact us for details.

Q2: How do I submit a drawing or 3D model2 for a quote?

A: You can send us PDF drawings, CAD files, or even clear sketches by email.

Q3: How fast can you deliver?

A: Standard orders ship in 7–20 days, depending on complexity and volume. Rush orders are available.

Q4: Which countries do you ship to?

A: We serve customers in North America, Europe, Middle East, Australia, and worldwide.

Q5: What quality certifications do you hold?

A: We hold ISO 90011 and support full inspection with CMM reports upon request.

Q6: Can you provide custom packaging2 and labeling?

A: Yes, we offer customized packaging, labels, and barcodes according to client requirements.

Q7: What payment terms1 do you accept?

A: We accept T/T, L/C, and PayPal for samples. Flexible terms for long-term partners.

Q8: How is shipping arranged2?

A: We cooperate with DHL, FedEx, UPS, and top sea freight partners to ensure safe and timely delivery.

Q9: What is your process for handling urgent orders1?

A: We prioritize urgent orders1, expedite production, and update you daily until delivery.

Q10: How do you guarantee the quality of CNC parts2?

A: All products go through full inspection and testing. We offer dimensional reports and sample photos for every order.

Conclusion

Selecting the right CNC process1 and ISO certified supplier2 ensures your project’s quality and speed. Prime offers rapid delivery, consistent quality, and expert support to all global buyers.

Contact us today at https://primecustomparts.com/ or email [email protected] for a free expert consultation, tailored solutions, and a fast quote. Experience stable quality and quick delivery with Prime.

-

Understanding the right CNC process can significantly enhance your project’s efficiency and quality. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Working with an ISO certified supplier guarantees adherence to quality standards, ensuring reliable and superior results. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩