How to Choose the Right Injection Molded Plastic Parts Manufacturer?

I’ve struggled with unreliable plastic parts suppliers before.

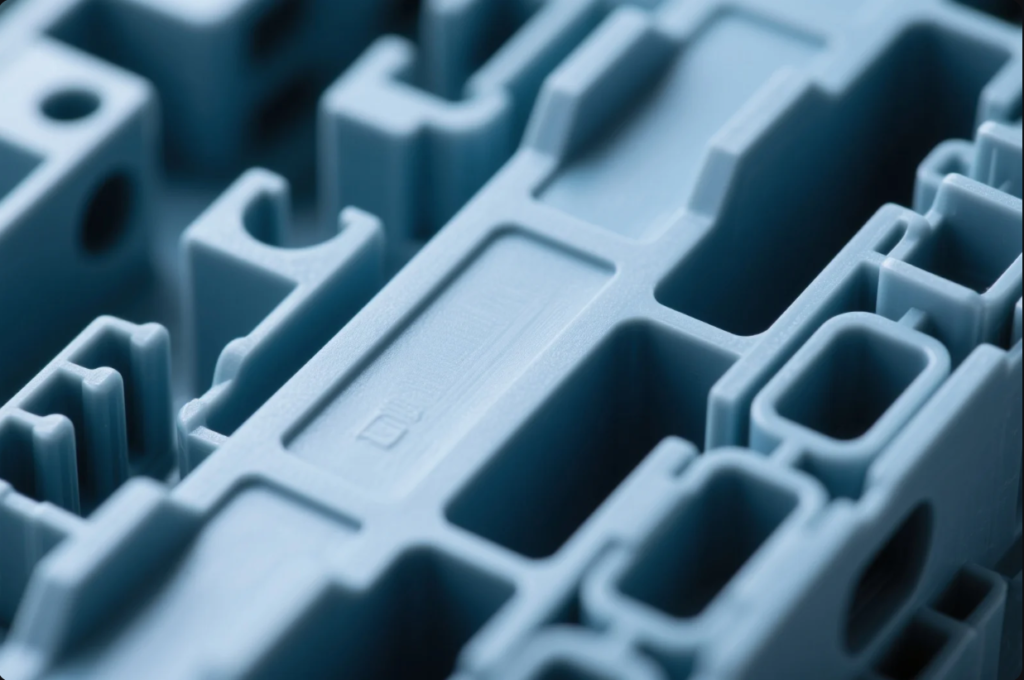

Injection molded plastic parts require precision, speed, and quality. Choosing the right supplier ensures your project succeeds.

I used to experience frequent delays and defective products due to poor supplier selection. These issues disrupted production, hurt customer satisfaction, and cost me money.

If you’ve faced similar challenges, this guide will walk you through how to select a plastic parts manufacturer that consistently delivers quality parts—on time and within budget.

Why is “injection molded plastic parts” a top search term for buyers?

Every week, engineers and procurement managers search this phrase to find reliable, certified factories that offer consistent quality and reasonable prices.

This keyword ranks high on platforms like Google and Alibaba because it reflects a high buyer intent for precision-made plastic components.

Many industries—like automotive, electronics, consumer goods, and medical devices—depend on injection molded parts. The term helps buyers filter out general suppliers and target those offering custom tooling and ISO-certified systems.

According to Plastics Today, the demand for high-performance molded parts is increasing, especially among OEMs seeking durable, cost-effective solutions. Buyers often include modifiers such as “ISO-certified plastic molding factory” or “thin-wall injection molding supplier” to narrow their options.

How do traditional, thin-wall, and fusible-core molding compare?

Choosing the wrong injection molding process can lead to costly design revisions and rejected parts.

Each molding process suits a different application. Selecting the best method is critical for part quality and project cost.

Traditional Injection Molding

Traditional molding is versatile. It handles most common applications such as appliance housings and structural electronic enclosures.

- Suitable for high or low volumes

- Accepts a wide range of resins

- Offers moderate cycle times and tight tolerances

According to Protolabs, this method works best when part geometry is simple and strength requirements are moderate.

Thin-Wall Injection Molding

Used for high-speed, lightweight products, thin-wall molding reduces material usage and cycle time dramatically.

- Ideal for parts with walls below 1 mm

- Requires high injection speed and pressure

- Demands premium tooling and temperature control

ENGEL’s thin-wall solutions explain how this method supports fast-moving consumer goods and medical packaging.

Fusible-Core Injection Molding

This advanced process is best for complex, hollow parts—like automotive HVAC ducts.

- Uses a sacrificial core that melts post-injection

- Allows internal channels without welding or assembly

- High tooling cost, longer cycle time

Top material brands like DuPont and BASF support this process with reinforced engineering polymers.

Molding Comparison Table

| Molding Type | Ideal Use Case | Cost Level | Speed | Complexity |

|---|---|---|---|---|

| Traditional | General-purpose components | Medium | Moderate | Moderate |

| Thin-Wall | Lightweight packaging | High | Very Fast | Simple |

| Fusible-Core | Hollow or multi-channel | Very High | Slower | Complex |

Understanding each process helps you make informed tooling and design decisions before issuing a purchase order.

What are the key criteria for evaluating a plastic parts supplier?

I once chose a supplier just because their factory looked clean in photos. That mistake cost me time and money.

Reliable suppliers combine strong equipment, strict quality control, and predictable delivery schedules.

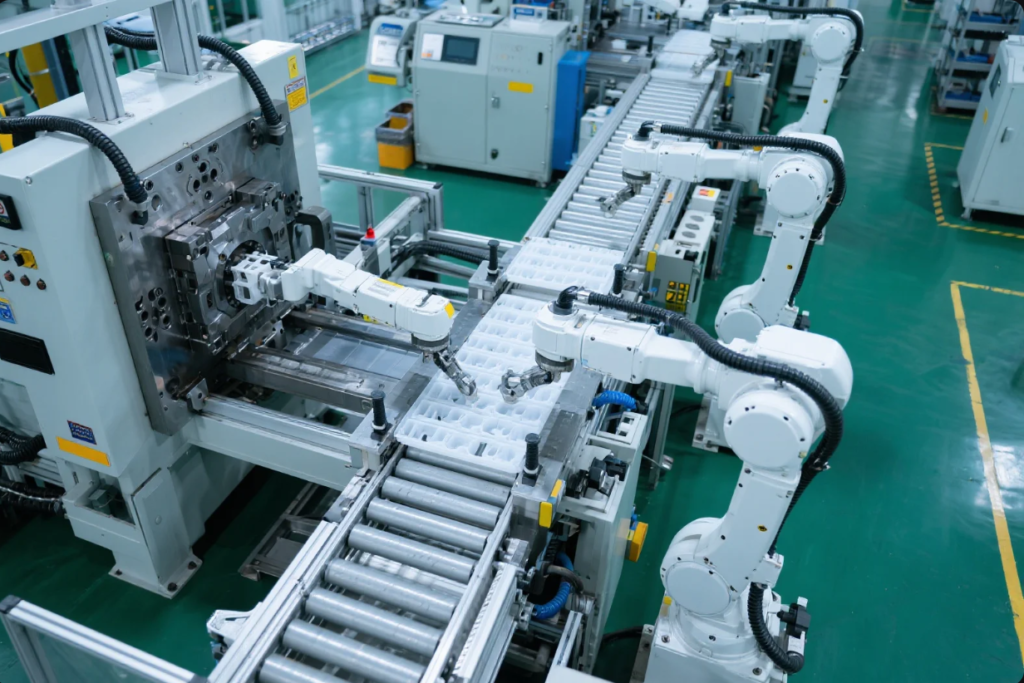

Check Their Equipment

Ask about:

- Machine size range (e.g., 80T to 1000T)

- Multi-cavity capabilities

- Mold temperature and humidity control

Modern factories like ENGEL and Sumitomo Demag showcase their automated lines to prove speed and stability. Prime operates 10 fully automated production lines and shares equipment specs transparently on request.

Examine Their Quality Control Process

Look for:

- ISO 9001 certification

- Digital inspection records

- Sample traceability reports

According to IQS Directory, top suppliers conduct in-line testing and offer full inspection logs. Prime offers real-time quality documentation and performs in-house lab testing for critical applications.

Evaluate Delivery Reliability

Reliable manufacturers:

- Estimate realistic lead times

- Share weekly production updates

- Offer shipment tracking

Carriers like DHL and Flexport help companies integrate logistics into their ERP systems. Prime provides dynamic tracking links and air or sea freight coordination.

Evaluation Checklist

| Factor | What to Look For | Prime Capability |

|---|---|---|

| Equipment | Modern, varied tonnage | 80T–1000T, multi-cavity tooling |

| Quality | ISO, test logs, COA | ISO 9001, FAI reports, inspection sheets |

| Delivery | Cycle time, updates, shipping | Express & ocean freight, real-time ETA |

How can we balance fast delivery with cost efficiency?

I used to think faster delivery always meant higher cost. But that’s not true.

Speed and cost can be optimized with smart scheduling, modular tooling, and lean systems.

Use Lean Scheduling

Lean systems like Kanban help prioritize urgent tasks while avoiding bottlenecks. This approach is explained well by Lean.org and implemented in ERP systems like Katana.

Prime uses color-coded dashboards and load balancing to ensure lines stay productive without delays.

Implement Modular Tooling

By using interchangeable mold inserts, suppliers reduce:

- Mold change time by 40%

- Setup costs by 15%

- Downtime between jobs

As Autodesk Fusion Operations suggests, modular design accelerates both prototyping and mass production. Prime applies this model for repeat orders with high ROI.

Apply Real-Time Inventory and Buffer Stocking

Reliable suppliers share daily production logs, track finished goods in transit, and pre-stock materials to eliminate delays. Odoo and SAP provide scalable inventory solutions.

Cost-Speed Optimization Table

| Strategy | Time Saved | Cost Impact | Use Case |

|---|---|---|---|

| Modular Tooling | -40% | -15% | Repeat orders |

| Kanban Flow | -25% | Neutral | Short lead time projects |

| ERP Tracking | -15% | -5% | Volume-based programs |

Fast delivery isn’t about rushing. It’s about being prepared, automated, and data-driven.

FAQs

What is the MOQ for custom plastic parts at Prime?

Our MOQ is 500 units. For new clients or prototype runs, we offer flexible options. Check our service page for details.

Do you support international shipping?

Yes. We ship globally through DHL, FedEx, UPS, and sea freight with customs handling.

What materials can be injection molded?

We mold ABS, PC, PBT, Nylon, PP, and more. View specs at MatWeb.

How do I get a quote?

Send your drawing and quantity to [email protected] or use our quote form.

What industries do you serve?

We support automotive, electronics, machinery, and appliances. Learn more via Ptonline.

Contact Us

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com

Contact Prime today for free design advice, detailed quotations, and packaging solutions tailored to your industry. Let us help you stay on schedule—with certified quality and global delivery.

Conclusion

Find a certified supplier who understands plastic parts and delivers fast. Contact Prime for free advice and fast quotes.