How to Choose the Right Metal Stamping Die for Precision Parts?

Why Choosing the Right Die Matters

I faced poor part quality and late shipments before.

It all traced back to the wrong die choice.

Once I learned how to evaluate stamping dies, my quality and delivery improved fast.

Summary:

Choosing the right stamping die impacts part accuracy, production cost, and delivery time.

This guide helps engineers and buyers select the correct die with confidence.

Learn more from Metal Stamping 101 – The Fabricator, Thomasnet, and Modern Machine Shop.

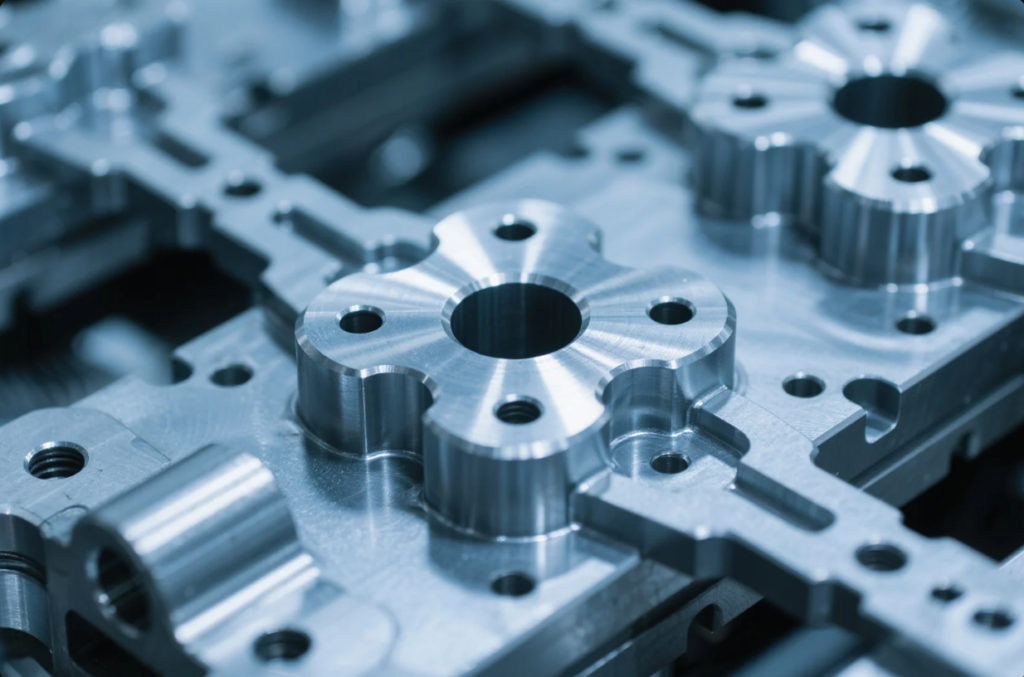

Die Material Selection: Tool Steel vs. Carbide?

I once used tool steel dies for medium-volume production.

Within months, I had to replace them.

Switching to carbide saved me thousands in maintenance.

Summary:

Tool steel is affordable but wears faster.

Carbide lasts longer under stress and reduces downtime.

The choice depends on volume, tolerance, and budget.

| Feature | Tool Steel | Carbide |

|---|---|---|

| Hardness | Medium | Extremely High |

| Wear Life | 100k–500k hits | 1M+ hits |

| Cost | Lower | 2–4x higher |

| Repairability | Easier | Difficult |

For small batches, tool steel from Carpenter Technology or Matmatch works well.

For high-volume runs, carbide tooling from Kennametal or Sandvik ensures long-term stability.

Also review the ASM Heat Treatment Guide for metallurgical insights.

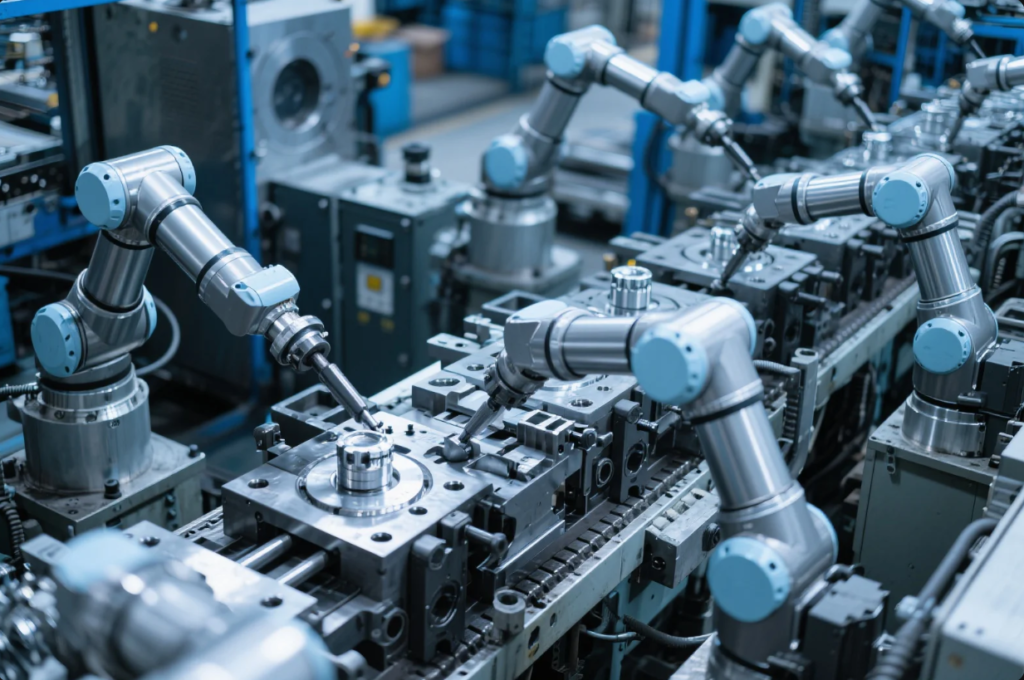

Precision Blanking vs. Conventional Punching Dies

I initially used punching dies for low-budget parts.

The results? Inconsistent edges, rework, and wasted materials.

Once I switched to precision blanking, the savings were real.

Summary:

Punching dies create rough edges and larger tolerances.

Precision blanking offers cleaner cuts and consistent dimensions.

It reduces finishing costs and improves product quality.

| Feature | Punching | Precision Blanking |

|---|---|---|

| Edge Finish | Rough, burrs | Smooth, clean |

| Tolerance | ±0.1 mm | ±0.02 mm |

| Secondary Processing | Usually needed | Rarely needed |

| Tooling Cost | Lower | Higher upfront |

Explore case studies on Practical Machinist, tool insights from AMADA, MetalForming Magazine, Cincinnati, and side-by-side comparisons on Engineering360.

Why ISO-Certified Tooling Matters

I once lost a client due to poor documentation.

Our supplier lacked ISO processes.

Now, every Prime tool is built in an ISO 9001-certified facility.

Summary:

ISO certification ensures consistent quality, traceability, and process control.

It protects buyers from defects and audit failures.

- Standardized Documents

- Mill Test Certificates (MTC)

- CMM and dimensional reports

- Process control for traceability

You can verify certifications at ISO.org, and review auditing tools via ASQ, Quality Digest, NIST, and SME.

8 Key RFQ Questions to Ask Your Die Supplier

In early projects, I didn’t ask enough questions.

Quotes varied wildly, and deadlines slipped.

Now I ask these 8 things before any RFQ is final.

Summary:

Well-crafted RFQs lead to better quotes and fewer delays.

Asking the right questions helps evaluate supplier reliability.

| # | Question | Why It Matters |

|---|---|---|

| 1 | What die material and hardness is used? | Confirms wear life |

| 2 | What tolerances can the tool hold? | Validates part accuracy |

| 3 | What is the tool life (in hits)? | Plans production maintenance |

| 4 | Are you ISO certified? | Assures quality process |

| 5 | What inspections are performed? | Ensures dimensional control |

| 6 | What is your lead time? | Keeps projects on track |

| 7 | Do you offer maintenance/support? | Reduces long-term costs |

| 8 | How do you pack for transport? | Prevents shipment damage |

Use RFQ resources from Procurement Leaders, GlobalSpec, Alibaba, Engineering Toolbox, and Autodesk GD\&T Guide.

FAQs

Q: What die is best for automotive parts?

A: Use carbide or precision blanking for volume and tight tolerances.

Q: Why are there huge price differences between dies?

A: Varies by material, precision, inspection, and after-sales support.

Q: Can Prime accept custom drawings?

A: Yes, in STEP, IGS, PDF and other formats.

Q: Is your packaging safe for international shipment?

A: We use anti-rust oil, foam protection, and strong wooden crates.

Q: What markets do you serve?

A: We ship to North America, Europe, the Middle East, and beyond.

Explore more: WikiMachinery, Thomas Insights, ToolingU-SME, Manufacturing.net, Made-in-China

Conclusion

The right stamping die ensures quality, speed, and cost-efficiency.

Start with strong questions and certified partners.

Contact Prime

Get free consultation, CAD review, and a detailed quote:

🌐 Website: https://primecustomparts.com/

📩 Email: [email protected]

We promise fast delivery, reliable precision, and smooth global logistics.

Contact us today to simplify your sourcing.