How to Choose the Right Supplier for CNC Metal Parts: 7 Key Factors to Consider

Choosing a reliable CNC metal parts supplier in 2025 can be difficult. Quality, delivery, and support vary greatly—and mistakes are expensive.

This guide explains the seven most critical factors when selecting a CNC parts supplier. It covers quality control, stock selection, machine types, pricing, and support.

Many buyers rush into quotes without evaluating the supplier’s capabilities. This leads to miscommunication, delays, and rejected parts. Here’s how to avoid that.

What Are the Key Factors for Selecting a CNC Supplier?

Not all CNC suppliers are the same. Many lack strict quality control or modern equipment.

The best CNC suppliers combine precision, speed, certifications, communication, and long-term support.

7 Critical Factors

| Factor | Why It Matters |

|---|---|

| 1. Quality System | Look for ISO 9001, traceability, and in-house QC |

| 2. Machine Capability | Multi-axis, turning-milling combo, micron tolerance support |

| 3. Material Knowledge | Know how to machine aluminum, steel, brass, etc. |

| 4. Tolerances Offered | Standard ±0.05 mm, tight to ±0.01 mm when needed |

| 5. Communication | Fast, technical replies and pre-sale DFM support |

| 6. Delivery Times | Can they ship within 7–15 days? |

| 7. Certifications & Experience | Industrial, medical, aerospace experience required |

🔗 See industry-certified CNC partners listed on Thomasnet or Xometry.

At Prime, we provide instant feedback on drawings, free DFM review, and video updates from our factory. That’s how we earned repeat buyers from Europe and North America.

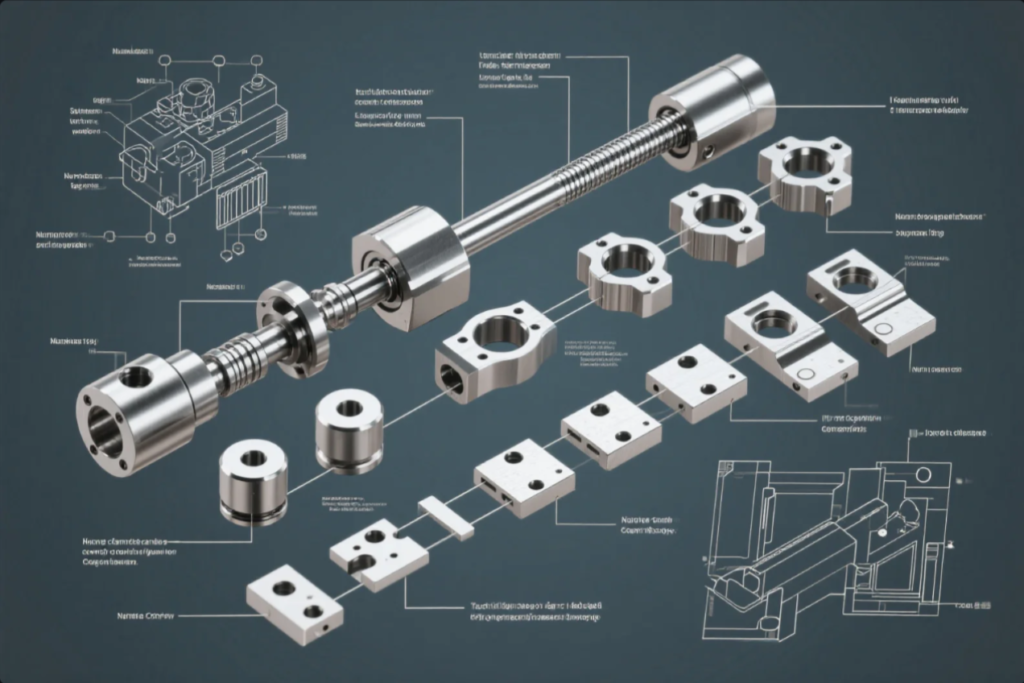

What Are the 7 Major Parts of a CNC Machine and Why They Matter?

Knowing the machine’s core parts helps buyers understand what’s behind good precision.

Each component impacts speed, repeatability, and surface finish. A reliable supplier maintains these regularly.

CNC Machine Main Components

| Part | Function |

|---|---|

| 1. Controller | Brain of the machine; executes G-code instructions |

| 2. Drive Motors | Moves axes with precision |

| 3. Spindle | Rotates the cutting tool at thousands of RPM |

| 4. Bed/Table | Supports the material; ensures stability |

| 5. Coolant System | Prevents overheating, removes chips |

| 6. Tool Changer | Automates tool swapping for complex parts |

| 7. Enclosure | Protects operator, reduces contamination |

🔗 Learn about modern CNC setups at CNC Cookbook.

Why does this matter to buyers? For example, a supplier with worn spindles or uncalibrated drives might deliver rough surfaces or incorrect hole diameters. Always ask about machine maintenance and calibration reports.

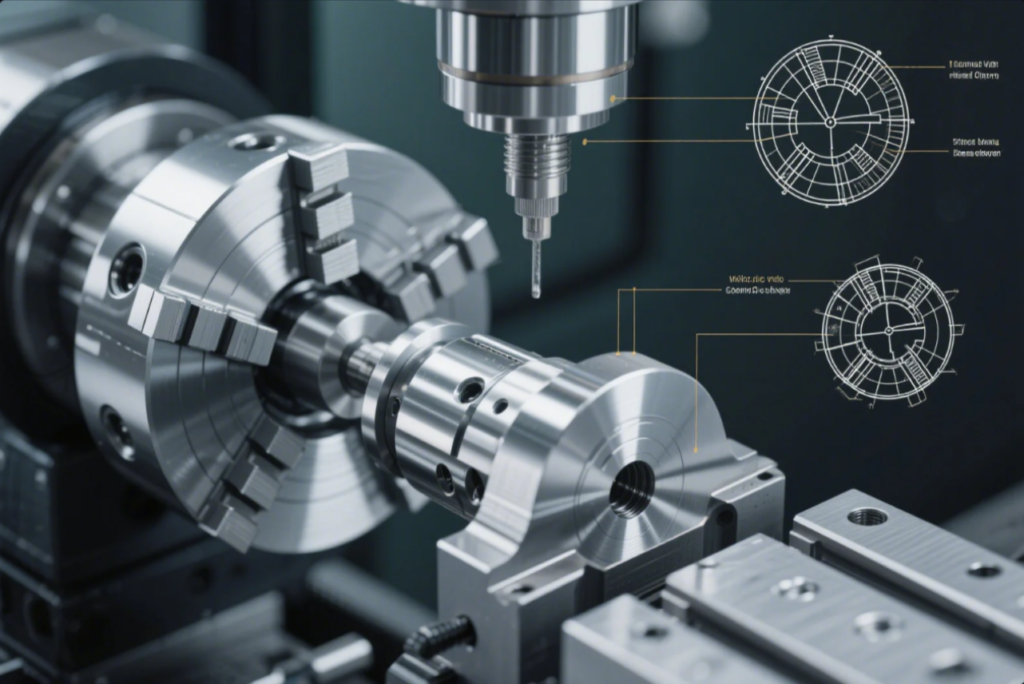

How to Choose the Right CNC Machine for Your Project?

Not all machines can handle every job. Matching the part design to the right machine saves cost and boosts accuracy.

Match the part’s shape, material, and tolerance to the correct machine type—like 3-axis, 5-axis, or turning centers.

Machine Selection by Use Case

| Project Type | Best Machine Type | Why It Works |

|---|---|---|

| Simple flat parts | 3-axis CNC milling | Low cost, fast setup |

| Round parts, shafts | CNC lathe or turning center | Precision concentricity |

| Complex 3D profiles | 5-axis CNC milling | Reduced setups, tighter tolerances |

| Deep cavities, tight angles | EDM (Wire or Sinker) | For inaccessible features |

🔗 Understand CNC types from HAAS Automation or Tormach.

At Prime, we match each part to the correct machine. We won’t mill a round shaft on a 3-axis just to save time—accuracy comes first.

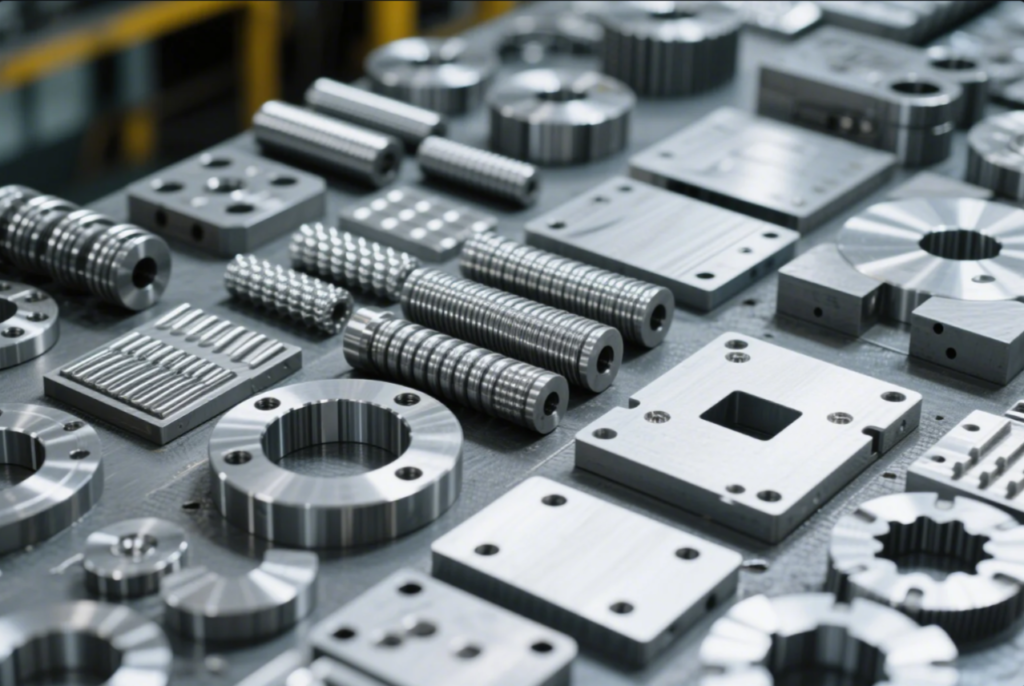

How to Select the Right Stock Material for CNC Machining?

Your material choice affects cost, machinability, and part lifespan. Choosing wrong leads to longer machining time or post-process failures.

Pick stock based on strength, corrosion resistance, weight, and finish needs. Let the supplier confirm availability.

Common CNC Materials and Stock Shapes

| Material | Stock Form | Notes |

|---|---|---|

| Aluminum 6061 | Round bar, plate | Affordable, good surface finish |

| Stainless 304/316 | Rod, flat bar | Strong, corrosion-resistant |

| Carbon Steel | Bar, square, block | Needs coating to prevent rust |

| Brass C360 | Bar, rod | Excellent machinability, good polish |

| Titanium Grade 5 | Round bar | Aerospace-grade, difficult to machine |

🔗 Compare materials at MakeItFrom.com or OnlineMetals.

At Prime, we stock 30+ alloys and offer full material traceability. We always check if your tolerance fits the material form—especially for warpage-prone metals like 304.

FAQs

Q1: How do I know if a supplier is using high-precision machines?

Ask for machine brand (e.g., HAAS, DMG Mori) and recent calibration reports. Trusted suppliers share this info.

Q2: Can I request both machining and finishing from one supplier?

Yes. Prime offers CNC plus anodizing, powder coating, polishing, and more.

Q3: What is the typical MOQ for CNC metal parts?

Most factories accept 10–50 pcs for prototypes. For lower cost, batch 100+ pcs.

Q4: Do I need to supply a 3D model?

Yes, STEP or IGES files help avoid errors. PDF drawings with tolerances also help.

Q5: What tolerance should I ask for?

Use ±0.05 mm unless the fit requires tighter. Tighter = more expensive.

Conclusion

Choose your CNC supplier carefully. Focus on quality, communication, and machine capability—not just price.

📩 Get free DFM review and same-day CNC quotes:

Email: [email protected]

🌐 Visit us: https://primecustomparts.com/

At Prime, we deliver ISO-certified precision parts with global shipping and 24/7 technical support.