How to Get Progressive Die Stamping Parts from China?

Progressive die stamping is one of the fastest and most cost-efficient ways to produce metal parts at scale.

This guide shows you how to get high-quality progressive die stamping parts from China—covering pricing, process flow, differences from transfer stamping, and trusted suppliers.

With over 20 years of export experience, Prime helps global buyers reduce cost, ensure quality, and speed up sourcing.

How much does progressive die stamping cost?

Pricing varies based on part complexity, material, volume, and number of die stages.

For medium-scale orders, the unit cost of progressive stamping can drop below \$0.10 USD per part—after amortizing tooling.

Typical cost breakdown:

| Cost Item | Range (USD) | Notes |

|---|---|---|

| Progressive Die | \$3,000 – \$20,000 | One-time cost, lasts 500K+ cycles |

| Per-Part Cost | \$0.03 – \$0.50 | Depends on volume and material |

| Material (Steel) | \$0.60 – \$1.50/kg | SS, CR steel, brass, copper |

| Setup Fee (if low volume) | \$200–\$600 | For trial or validation runs |

Prime supports both die ownership and cost-sharing options for long-term clients.

🔗 Request Quotation

What is the process of progressive metal stamping?

Progressive stamping uses a die set with multiple stations. A coil of metal feeds through each stage, performing one operation per step.

Common operations:

- Feeding – metal strip enters die

- Piercing – holes or slots punched

- Forming – bends, flanges created

- Cutoff – part is sheared off the strip

Each part is completed at the final station. The process is fast, precise, and minimizes waste.

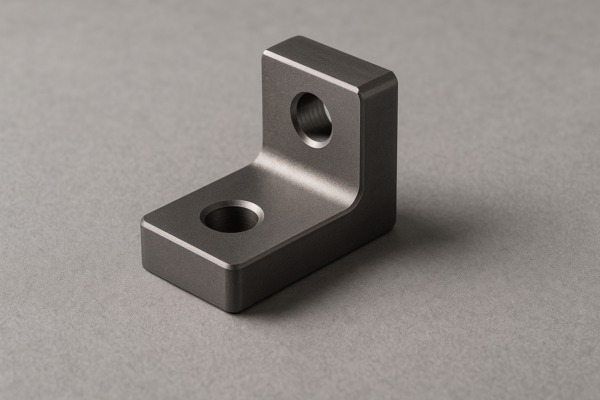

Prime runs 10–125 ton presses and supports strip widths up to 300mm. Our clients use this for:

- Electrical contacts

- Terminal brackets

- Automotive clips

- Enclosures and shields

🔗 Explore Prime’s stamping parts

What is the difference between progressive die stamping and transfer press stamping?

Both are used for high-volume metal stamping, but they differ in how the part moves between stations.

| Feature | Progressive Die Stamping | Transfer Press Stamping |

|---|---|---|

| Material Handling | Strip-fed, stays attached between steps | Blank moves between dies using transfer fingers |

| Speed | Very fast | Slower due to transfer system |

| Best For | Flat or lightly formed parts | Deep draws, large 3D parts |

| Tooling Complexity | Higher upfront die integration | Modular die design |

| Part Separation | Final step in the die | Each die produces one forming operation |

Prime offers both technologies. We’ll help you choose based on tolerance, geometry, and cost.

What is the die stamping process?

Die stamping refers to shaping metal using a custom tool (die) and a press machine. It includes single-station and multi-station (progressive) setups.

Steps in full die stamping workflow:

- Tooling Design – 2D/3D CAD → CAM → Die manufacture

- Trial & Adjustment – First articles, dimension checks

- Mass Production – Coil feeding, progressive press operation

- QC + Packaging – Visual + dimensional inspection + crate packing

All Prime dies are made in-house or via long-term tooling partners. We maintain them between cycles, and provide tooling life guarantees for volume orders.

Conclusion

Progressive die stamping is one of the best ways to mass-produce metal parts cost-effectively—with speed, repeatability, and low waste.

✅ If you’re sourcing from China, Prime offers:

- In-house die design + CNC machining

- 10+ press lines (40–125 tons)

- Rapid tooling + prototype validation

- Global shipping with export crates

📩 Get Quote Today

📧 Email: [email protected]

🌐 Visit: https://primecustomparts.com

From terminal clips to bracket housings, Prime is your trusted partner for progressive die stamping in China.