How to Make Custom Metal Parts?

Leading paragraph: Custom metal parts are integral in various industries. Understanding how to make them ensures that you can meet specific project requirements. So, how do you go about making these parts?

Snippet paragraph: Making custom metal parts involves various techniques. From design to fabrication, the process includes machining, welding, and more to achieve precise results.

Transition paragraph: In this article, we’ll dive into the process of making custom metal parts, covering the necessary steps and considerations.

How Much Does It Cost to Fabricate Metal Parts?

Leading paragraph: When it comes to fabricating custom metal parts, cost can be a major consideration. Understanding the factors that influence price can help you make an informed decision.

Snippet paragraph: The cost of fabricating custom metal parts depends on materials, complexity, and production volume. Prices can range from a few dollars to thousands per piece.

Dive-Deeper paragraph: Fabricating metal parts can vary widely in cost. Factors that influence the price include:

Key Cost Factors in Metal Fabrication:

| Factor | Description |

|---|---|

| Material Type | Stainless steel, aluminum, and titanium tend to be more expensive than basic metals like iron. |

| Part Complexity | Intricate designs and fine tolerances will increase the cost due to the need for more advanced techniques. |

| Quantity | Producing large quantities often reduces the per-unit cost. |

| Machining Time | The time required to cut, weld, or shape the metal part affects the overall cost. |

| Finishing Process | Additional processes such as painting, coating, or heat treatment add to the cost. |

On average, simple metal parts can cost between $5 and $50 per piece, while highly complex or low-volume production parts could cost several hundred or more.

How to Make a Metal Part?

Leading paragraph: Making a metal part from scratch involves several steps. It requires careful planning, selection of materials, and utilizing the right machinery to ensure precision.

Snippet paragraph: The process of making a metal part involves designing, selecting the material, and machining. These steps ensure the final product meets specific requirements.

Dive-Deeper paragraph: The process of making a custom metal part typically involves the following key stages:

Key Stages of Metal Part Fabrication:

- Design and Engineering: The first step is designing the part using CAD (Computer-Aided Design) software. This step involves determining the dimensions, material, and any special features required.

- Material Selection: Choose the material best suited for the part. Common options include steel, aluminum, and titanium, based on the required strength, weight, and corrosion resistance.

- Cutting or Shaping: Using machines like CNC mills or laser cutters, the material is shaped into the desired form. This can involve cutting, drilling, and other methods to achieve the exact dimensions.

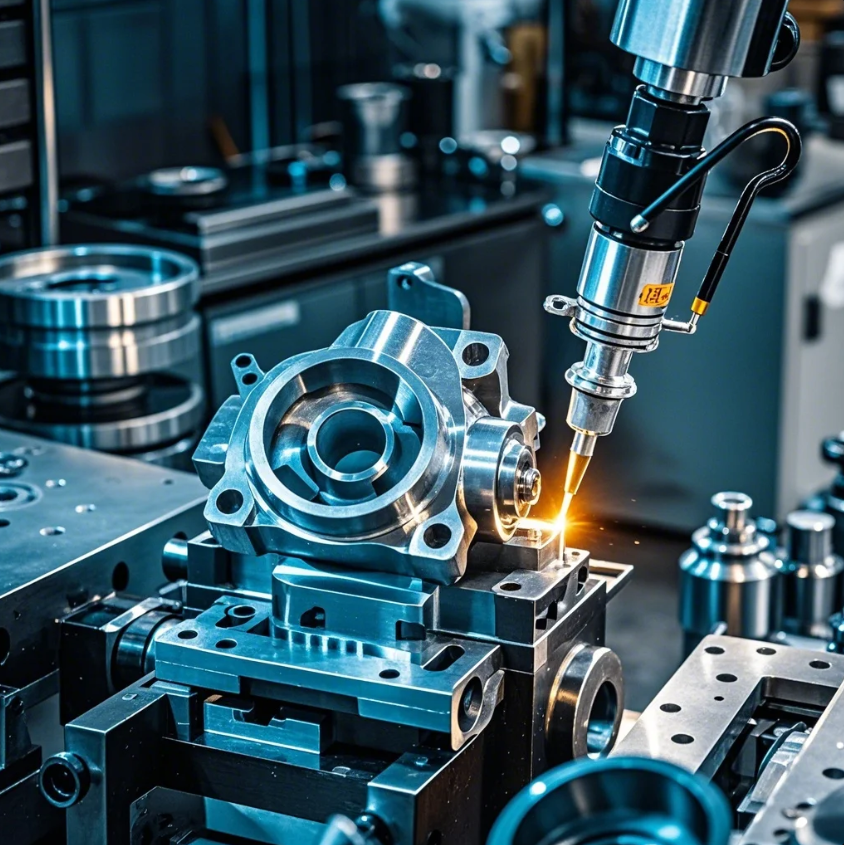

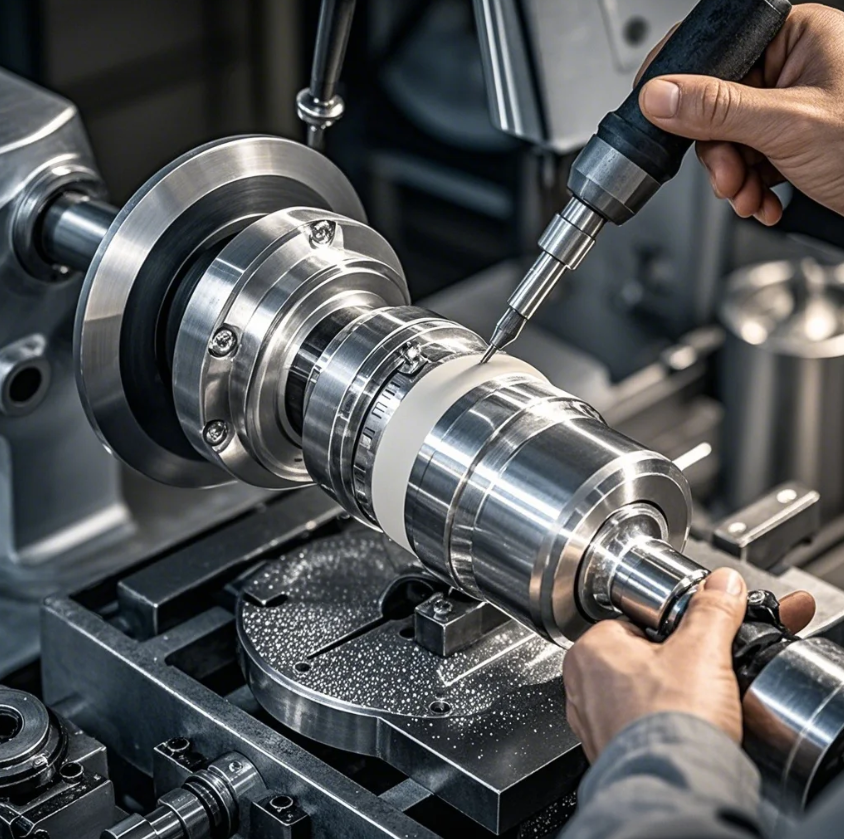

- Machining: For more detailed precision, CNC (Computer Numerical Control) machines are used. These machines cut, drill, and shape the material with high accuracy.

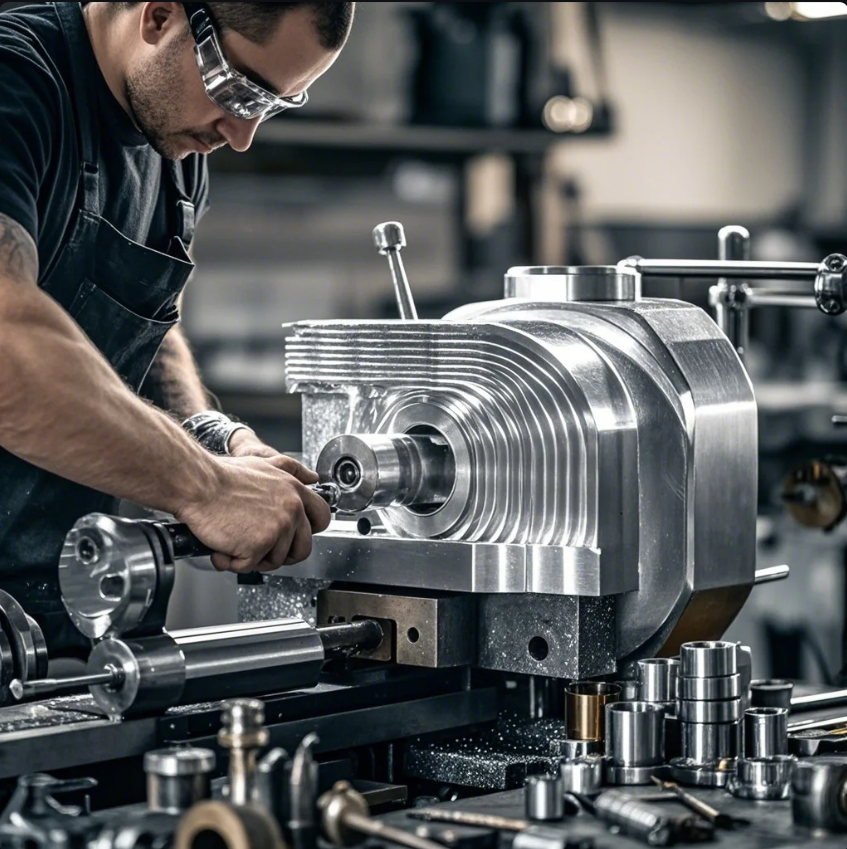

- Assembly or Welding: If the part consists of multiple components, they are assembled or welded together. Welding is commonly used for strong, permanent joints.

- Finishing: Once the part is assembled, it is cleaned, polished, and sometimes coated for protection or aesthetics.

This process ensures that the metal part is accurate, durable, and ready for use in various applications.

Do You Use Precision Machines to Build Custom Metal Parts?

Leading paragraph: Precision is crucial when making custom metal parts, especially for industries that require high tolerance and accuracy. But, do you really need precision machines?

Snippet paragraph: Yes, precision machines like CNC machines and lathes are often used to create custom metal parts. They ensure high accuracy and consistency in every part produced.

Dive-Deeper paragraph: Precision machining is essential when creating custom metal parts. These machines allow for intricate details and tight tolerances that manual methods cannot achieve. Here are the main precision machines used:

Types of Precision Machines Used for Custom Metal Parts:

| Machine Type | Purpose |

|---|---|

| CNC Machines | Used for precise cutting, drilling, and shaping. |

| Laser Cutters | Provides high precision cuts for complex shapes. |

| Lathes | Used for turning and shaping cylindrical parts. |

| Mills | Removes material to create detailed shapes. |

| EDM (Electrical Discharge Machining) | Used for cutting complex shapes in hard materials. |

These machines ensure that the parts are produced with high accuracy, reducing the risk of defects and increasing the quality of the final product.

How Do You Become a Metal Fabricator?

Leading paragraph: Becoming a metal fabricator requires a combination of skills, knowledge, and experience. But what does it take to get started in this field?

Snippet paragraph: Becoming a metal fabricator typically involves learning welding, machining, and other fabrication techniques. It’s a career that requires hands-on experience and technical knowledge.

Dive-Deeper paragraph: To become a metal fabricator, you typically need to go through the following steps:

Steps to Becoming a Metal Fabricator:

- Education: Many fabricators begin with a high school diploma, but pursuing further education in welding, machining, or engineering can be beneficial. Some technical schools offer specialized programs in metal fabrication.

- Apprenticeships: Gaining hands-on experience is crucial. Apprenticeships allow aspiring fabricators to work under experienced professionals to learn the trade.

- Certifications: Obtaining certifications such as those from the American Welding Society (AWS) can boost your credibility and career prospects.

- Experience: Like most trades, experience plays a vital role. The more you work with metal, the more you’ll learn about techniques and tools.

- Specialization: Many fabricators choose to specialize in specific areas, such as welding, CNC machining, or sheet metal work.

This career path combines creativity, technical skills, and problem-solving, making it ideal for those interested in working with their hands and manufacturing custom parts.

Conclusion

Making custom metal parts involves a well-defined process that requires the right materials, tools, and techniques. Whether you’re working with precision machines or seeking to become a skilled fabricator, the process is detailed and technical. At Prime, we specialize in high-quality metal part fabrication with flexible customization options. Contact us today for a free consultation and to discuss your specific requirements.