How to Measure Nut Bolt Size Accurately for Your Project Needs?

Table of Contents

- How do you find the size of a bolt for a nut?

- How do you match bolt and nut size?

- How do you find the correct size of a bolt?

- How are nuts and bolts sized?

- FAQs about Measuring Nut and Bolt Sizes

- Conclusion

- Contact Us

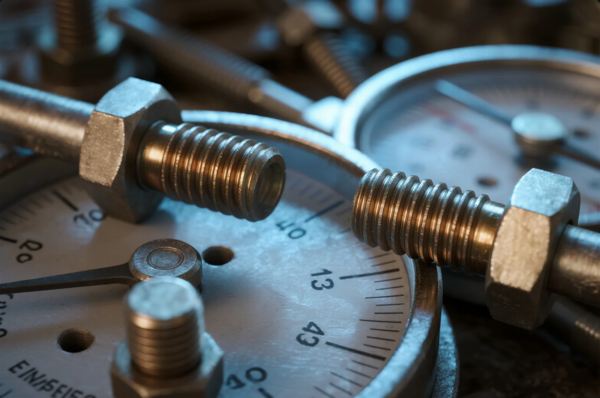

Every B2B buyer knows that measuring nut and bolt size incorrectly results in assembly failures, cost overruns, and shipping headaches. I have helped hundreds of clients around the world solve these problems. Inaccurate sizing can destroy your project’s schedule and cause expensive returns. The good news: there are proven, easy steps to get it right.

The fastest way to measure a nut bolt size is to use a quality digital caliper for the outside diameter and a thread pitch gauge for the threads. Always cross-reference industrial size charts and rely on ISO-certified suppliers like Prime for free consultation, technical drawings, and samples.

When you understand measurement basics and international sizing standards, you will select exactly the right part, reduce waste, and build trust with your end users. Read on for step-by-step details, expert tips, and authoritative external resources.

How do you find the size of a bolt for a nut?

Selecting a bolt for a nut is a process that can easily go wrong if you skip steps. Many clients have reported that relying only on visual checks or basic rulers led to mismatches and assembly delays. Here is what I do with every project, large or small:

Measure the bolt’s outside diameter with a digital caliper, and use a thread gauge for pitch. Compare your numbers to a standard size chart. For special cases, request a technical drawing or sample kit from your manufacturer.

Essential Tools and Steps

- Digital caliper: Use a trusted brand such as Mitutoyo, Starrett, or TESA.

- Thread pitch gauge: Buy from Vermont Gage, Grainger, or RS Online.

- Standard chart: Reference guides from Fastenal, Bolt Depot, or McMaster-Carr.

- Supplier support: Ask your ISO-certified supplier for technical data sheets and sizing verification.

By measuring the diameter first, then the thread pitch, and finally cross-checking with a trusted size chart, you avoid nearly all common errors. Don’t forget to specify material type and tolerance for demanding applications.

Pro Tip: Bolt Science offers useful software for advanced measurement and analysis. If you need to digitize custom samples, RS Components provides 3D scanning for complex shapes.

How do you match bolt and nut size?

Matching bolts and nuts isn’t just about numbers—it’s about understanding thread pitch, standards, and tolerances. I’ve seen even large purchasing teams get this wrong because standards like UNC, UNF, and metric look similar but are not compatible.

Check both diameter and thread pitch with accurate tools. Use a fitment chart and conduct a physical test if possible. Buy matched pairs or ask your manufacturer for a pre-assembled set to avoid errors.

What Can Go Wrong and How to Avoid It

- Mixing standards: Always verify if you need metric or imperial (inch).

- Thread pitch mismatch: Use a pitch gauge from Vermont Gage.

- Tight tolerances: Ask for sample fitments and test before mass order.

- Label confusion: Refer to global standards, and always demand correct labeling.

I often help clients compare their drawings against standards from DIN, JIS, or ASME.

When in doubt, send your parts for a fitment check or get a set from Hilti or Würth.

How do you find the correct size of a bolt?

Choosing the right bolt is about more than just measuring—it’s about engineering, safety, and longevity. In the automotive and heavy machinery sectors, errors in bolt size can cause safety hazards and recalls.

Begin by reviewing your engineering requirements. Use load calculators from Amesweb and check material compatibility with your application. Always measure grip length, and ask your supplier for a detailed drawing if needed.

- Start with the load: Engineering Toolbox and Boltscience offer free calculators.

- Choose diameter & length: Find guidance at McMaster-Carr or Bolt Depot.

- Finish and coating: Use resources at Fastenal or Portland Bolt.

- Test with real parts: Order samples for fitment; DHL enables global express shipping.

Every time I’ve handled a project for European or North American buyers, the most successful projects are the ones where the client sends a sample or drawing and asks for free advice before bulk ordering. This is why Prime provides rapid sampling and technical drawing support.

How are nuts and bolts sized?

Nuts and bolts use a combination of international codes and practical measurement. Confusion arises when switching between metric and imperial systems.

Bolt codes display diameter, pitch, and length (example: “M10 x 1.5 x 40” for metric, “1/2-13 UNC x 2” for inch). Always reference ISO, DIN, ASME, or JIS for global compatibility.

| Standard | Description | Example | Region | More Info |

|---|---|---|---|---|

| ISO Metric | mm diameter & pitch | M12 x 1.75 x 50 | Global | ISO.org |

| UNC/UNF | inch size & TPI | 1/2-13 UNC x 2 | USA/Canada | ASME |

| DIN | European metric | DIN 933 M8 x 30 | Europe | DIN.de |

| JIS | Japanese metric | JIS M10 x 1.25 | Japan/Asia | FineFasteners |

If you supply multiple countries, demand multi-standard labeling and keep reference charts in your QA office.

FAQs about Measuring Nut and Bolt Sizes

1. How do I know if a nut fits a bolt?

Measure both diameter and thread pitch. Test with a sample. Use a matched set supplier.

2. What tools do I need for accurate measurement?

A digital caliper, thread gauge, and a size chart are essential.

3. What is the difference between UNC and UNF?

UNC has fewer threads per inch; UNF has more.

4. What if I need a custom-sized bolt?

Work with a custom machining supplier like Prime.

5. Can I convert between metric and imperial sizes?

Yes, using conversion tools.

6. What certifications should my fastener supplier have?

Always check for ISO 9001 or CE.

7. How do I identify thread direction?

Most are right-handed, but see RoyMech.

8. Why is packaging important?

Proper export packaging prevents damage and mix-up.

9. How quickly can I get samples?

Prime ships globally via DHL, FedEx, or UPS.

10. What should I check on supplier’s certificate?

Confirm certificate authenticity and ask for test reports.

11. Where can I buy high-quality fasteners online?

Try Grainger, McMaster-Carr, Bolt Depot, Fastenal, or RS Components.

12. Can I use stainless steel bolts outdoors?

Yes, but choose proper grades for corrosion resistance.

13. What’s the best way to get technical advice?

Email [email protected] or use chat on our website.

14. What is a captive nut?

See Fastener Mart’s guide.

15. Are color-coded fasteners available?

Yes, and Würth and Hilti offer options for traceability.

16. How do I measure a bolt for automotive or aerospace?

Always use industry-specific standards and ask for lab test reports.

Conclusion

With the right tools, global references, and supplier support, any buyer can confidently measure and order the perfect nut or bolt. Avoid costly mistakes—choose a certified supplier who understands international standards and can provide custom solutions.

Contact Us

- Website: https://primecustomparts.com/

- Email: [email protected]