How to Reduce Costs in Custom Metal Welding Parts: Top Proven Strategies?

Costs keep climbing1, and schedules slip2. I face this often. I fix both with clear, simple steps.

You can cut welding costs1 by aligning materials, design, processes, and logistics. Choose fit-for-purpose metals2 and consumables. Simplify joints and fixtures. Match MIG, TIG, or robots to volume and tolerance. Protect value with strong packaging and predictable routes.

I share practical checks1 and templates2 you can use this week. I also include tables and examples. Then you can move fast with low risk.

Material Choices: Selecting Cost-Effective Metals and Welding Consumables?

Many teams over-spec metals and wires. Costs rise, and cycle time grows. I stop this waste with clear fit tests1 and quick trials2.

Match metal grade1 to real loads and environment. Standardize thickness and tube sizes. Choose wires and gases that reduce passes and cleanup. Validate choices with samples, MTRs, and photos.

Dive Deeper: A Material and Consumable Strategy That Protects Margin

Right-size metals, not myths

I start with duty cases, safety factors, and finish needs. Then I right-size steel grade and thickness. Q2351 often suits painted frames and brackets. Q345 fits higher loads at similar weight. 304 stainless2 fits true corrosion risk, not office rumors. I also lock standard sheet and tube sizes, so suppliers pull fast stock. As a custom stamping parts supplier and a custom welding parts OEM factory, I keep common gauges ready. Therefore, lead times drop, and scrap falls. I record mill test reports and trace each heat number, so audits stay easy and fast.

Consumables and parameters that save minutes

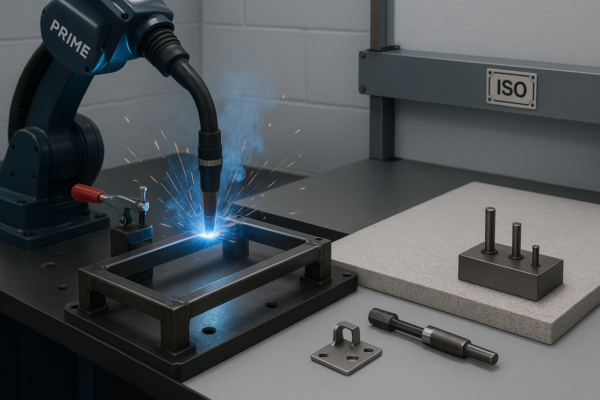

I run ER70S-61 with 80/20 gas for a smooth arc and low spatter. Outdoors, I switch to flux-core to resist wind. I replace contact tips and liners on schedule, so burnbacks stop. Then beads stay clean, and grinding time shrinks. I also use pulse MIG2 on thin walls, so heat input stays low. As an ISO certified casting parts manufacturer and robotic welding partner, I document settings by SKU. Therefore, shifts repeat the same quality and speed every week.

| Lever | Choice | Benefit | Trade-off |

|---|---|---|---|

| Base metal | Mild vs stainless1 | Lower price; faster cut | Needs coating |

| Thickness | 3 mm vs 4 mm | Less metal; less weld | Check stiffness |

| Wire type | Solid vs flux-core2 | Clean bead indoors | Wind sensitivity |

| Gas mix | 80/20 vs CO₂ | Smoother arc; faster travel | Slightly higher gas spend |

| Form | Standard tube sizes | Shorter lead; less scrap | Minor redesign |

Design for Welding (DFW): Simplifying Joints and Reducing Labor Time?

Complicated joints1 slow welders and increase defects. Extra pieces also inflate fixture cost2. I cut steps while I protect strength and alignment.

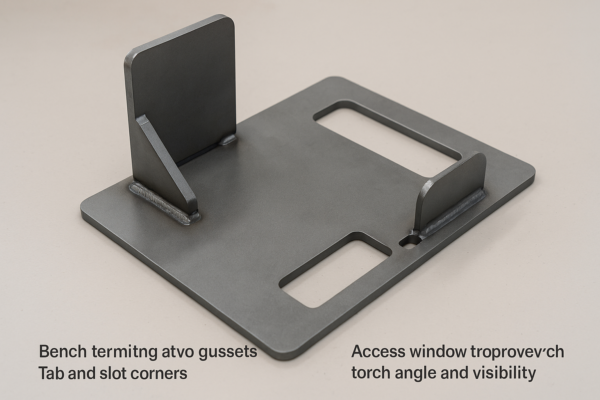

Use straight, reachable joints with consistent gaps. Replace multi-piece weldments1 with bends or stampings. Add tab-and-slot features2 for self-location and quick setup across shifts.

Dive Deeper: Designs That Weld Faster and Distort Less

Simplify parts first, welds second

First, I remove double-sided fillets1 when one side carries the load. Next, I add reliefs so the nozzle hits the root cleanly. Then I keep joint thickness consistent, so heat stays even. I standardize fillet sizes to stop oversize beads and extra passes. Therefore, wire usage drops, and cycle time falls. As a CNC parts precision machining2 partner, I align machined faces with weld geometry. So tolerances stay stable after cooling and paint.

Fixtures that guide the process

I design parts to self-locate with tabs and slots1. I set stop blocks and quick clamps, so cycle time stays stable. I mark datum faces, so operators load parts the same way. Then setup time falls across shifts and teams. I also publish fixture photos and QR-coded job cards2. Therefore, training stays short, and results stay repeatable.

| DFW Rule | Action | Typical Saving | Note |

|---|---|---|---|

| Reduce pieces1 | Bend or stamp, not weld | 10–25% labor | Strong effect on brackets |

| Single-side fillet | One pass, right size | 5–15% wire | Verify load case |

| Access window | Clear torch path | 5–10% cycle | Improves penetration |

| Tab-and-slot2 | Self-fixturing | 10–20% setup | Faster changeovers |

| Consistent gaps | CAD stack-up plan | 3–8% rework | Less distortion |

Process Optimization: MIG, TIG, and Robotic Welding — Which Saves the Most?

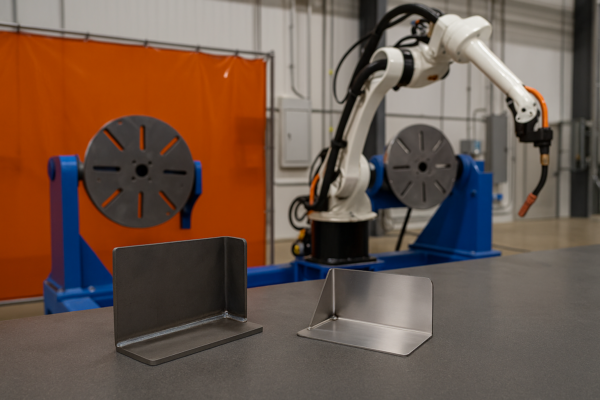

Each process shines in a specific zone. I match the process to volume, tolerance1, and finish needs. Then I prove the plan with time studies2.

Use MIG for speed on mild steel frames1. Use TIG for thin or visible seams2. Deploy robots on repeat parts when fixtures and takt justify the change.

Dive Deeper: Pick the Torch, Prove the Takt, and Scale

Time studies that reflect real work

I time three samples per variant, not one. I include tack, weld, inspect, and touch-up. Then I calculate travel speed and wire usage. I also log changeovers and consumable swaps. Therefore, you see true takt1, not wishful numbers. I share a clean spreadsheet with break-even points2. You choose with data, not guesses, and you defend the plan with ease.

Sequence planning and distortion control

I plan weld order to balance shrinkage. I use staggered runs1 and opposing seams. I add stitch welds where strength allows. Then I measure flatness and adjust clamps. I set a first-article check at three parts per shift. I use fillet gauges2 and macro-etch coupons on key SKUs. Therefore, quality holds as volume scales across lines.

| Process | Best For | Speed | Quality | Robot Ready | Notes |

|---|---|---|---|---|---|

| MIG | Frames, brackets | High | Good | Yes | Pulse reduces spatter |

| TIG | Thin, cosmetic seams | Low–Med | Excellent | Limited | Skill dependent |

| Robotic MIG1 | Repeat parts | Very High | Consistent | Yes | Needs robust fixtures |

| Hybrid2 | Mixed thickness | Med–High | Very Good | Possible | TIG root + MIG fill |

Supply Chain and Packaging: Cutting Transportation, Storage, and Rework Costs?

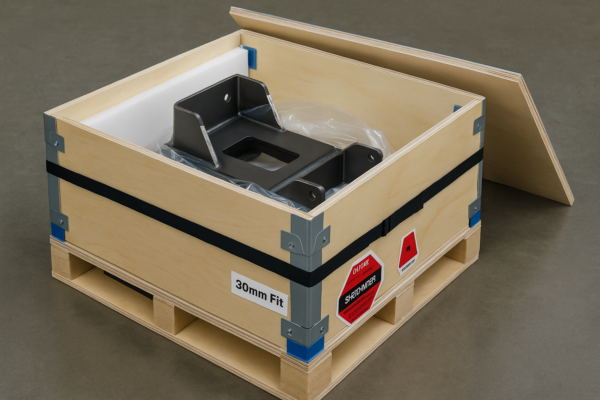

Costs do not end at the weld cell1. Freight, storage, and damage2 also hit margin. I make the lane predictable and the crate unbreakable.

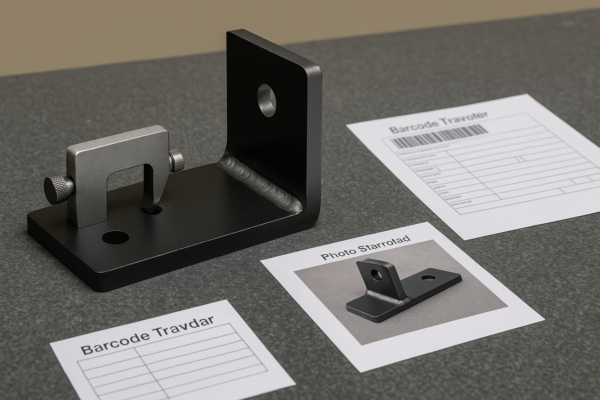

Consolidate suppliers, set min-max levels, and fix weekly sailings. Use stackable crates with foam and VCI1. Add barcode labels, check photos, and shock indicators2 to protect value in transit.

Dive Deeper: Make Your Flow Reliable and Your Crates Tough

Inventory and routing that reduce firefighting

First, I map the route from steel coil to your shelf. Next, I assign owners for each lane and carrier. Then I set reorder points1 and safety days by SKU. I fix sailings or flights by week, not luck. Therefore, you reduce spot spikes and urgent emails. I track OTIF2 and claims and share the dashboard weekly. As a wholesale-only factory with ten lines, I also combine loads across SKUs. So rates improve, and schedules stabilize for peak seasons.

| Area | Action | Cost Impact | Risk Impact |

|---|---|---|---|

| Supplier base | Fewer, stronger partners1 | Lower admin time | Better stability |

| Inventory | Min-max and kanban2 | Less tied cash | Fewer stockouts |

| Routing | Fixed weekly sailings | Lower spot rates | Higher predictability |

| Packaging | Stackable crates, VCI, foam | Fewer damages | Safer stacking |

| Labels | Barcodes and photos | Faster receiving | Fewer disputes |

Packaging that prevents damage, not just hides it

I fit foam or EPE to the part and block heavy frames. I use VCI for carbon steel1 and desiccants for sea routes. Then I label crates on two sides and on the lid. I include packing photos and a checklist inside each crate. Therefore, receiving moves faster, and disputes fade. I learned this with Kevin, a US buyer. He feared crushed boxes and missed seasons. We redesigned crates, locked a weekly sailing, and added loader photos. Returns fell near zero, and shelves stayed full during peaks. As an industrial fasteners wholesale2 and metal parts supplier, I hold this standard for every lane.

Conclusion

Choose fit materials, simplify joints, optimize processes1, and enforce strong logistics to reduce welded part cost2 quickly and safely.

Please contact Prime today for a free consultation, quotation, and custom plan. Share your drawings, target price, and deadline, and I will align both. Shandong Prime International Trade Co., Ltd., founded in 1993, holds ISO quality certification. We operate ten production lines for welding, stamping, casting, fasteners, CNC, and plastics. As a global B2B wholesale partner, we deliver fast and keep quality stable. We export to North America, Europe, the Middle East, Australia, and more. Send an inquiry on our website now, and I will reply quickly with a firm lead time, a clear cost-down roadmap, and a risk plan that protects your season.

Contact Us

📧 Email us: [email protected]

🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

-

Learn about innovative methods to streamline manufacturing processes for better productivity and cost savings. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore strategies to minimize costs in welded parts, ensuring efficiency and safety in production. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

One Response

Ive read several just right stuff here Certainly price bookmarking for revisiting I wonder how a lot effort you place to create this kind of great informative website