How to Reduce the Price of Custom Metal Parts, and What Advantages Does Steel Have Over Aluminum?

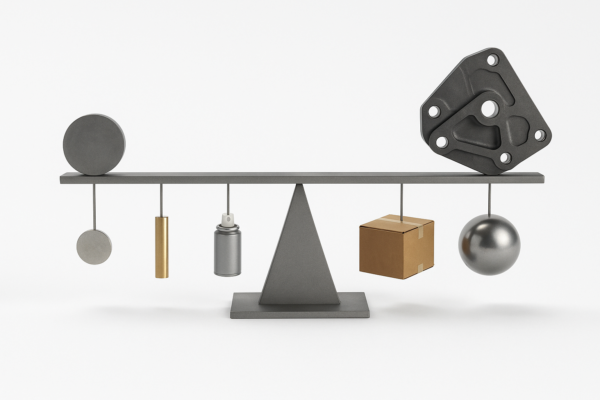

High unit prices, delays, and shipping damage inflate total landed cost1. Choosing the right metal—and right finish2—solves most of it.

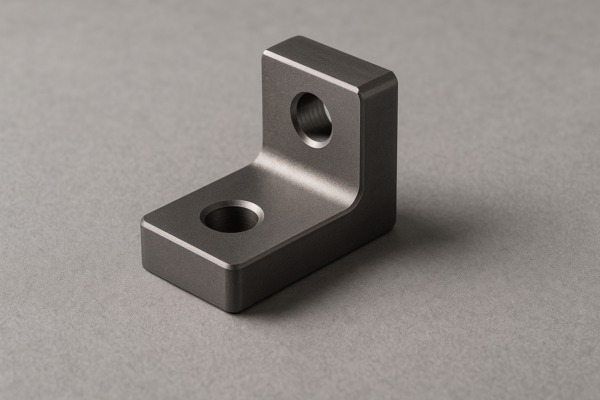

To reduce custom metal-part cost1, match material to function and finish. Steel typically offers lower cost per kg and higher strength/wear resistance. Aluminum cuts weight, often machines faster, and resists general corrosion but may need anodizing. Optimize wall thickness, tolerances, and coatings to avoid over-engineering, rework, and unnecessary processing.

Below I compare strength1, weight, finishes, tolerances2, and shipping—so you can decide quickly and issue an RFQ with confidence.

Difference Between Steel vs Aluminum: Strength & Cost?

Overbuilding1 and mismatched finishes2 add cost with no benefit.

Steel is generally stronger and cheaper per kilogram; aluminum is about one-third the density of steel, lowering freight and handling effort. Pick steel for heavy loads1 and abrasive contact; pick aluminum for weight-critical parts2—then lock the finish, tolerance, and inspection plan to avoid hidden downstream costs.

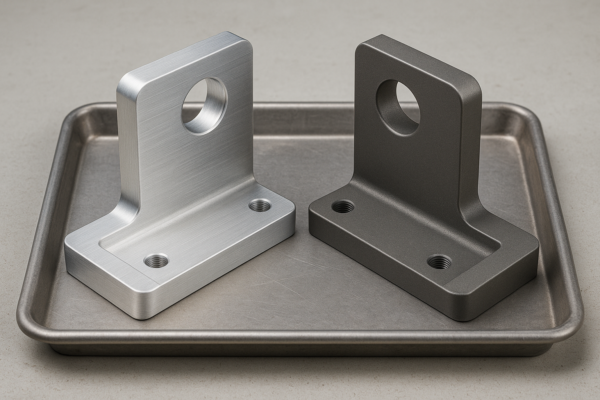

Steel and aluminum differ far beyond sticker price. Density sets logistics: typical steels are \~7.85 g/cm³ while aluminum is \~2.70 g/cm³—roughly a two-thirds mass reduction for the same volume (Engineering Toolbox). Strength ranges overlap, but use-cases diverge: low-carbon steels cluster around \~400–600 MPa tensile; alloy steels (e.g., 4140) go higher, while 6061-T6 sits \~290–320 MPa and 7075-T6 can exceed 500 MPa (MatWeb). Aluminum often runs shorter machining cycles due to lower cutting forces, but thin walls can deflect; steel tends to hold shape during aggressive cuts. For coatings, many steels use zinc plating or powder coat; aluminum is commonly anodized per ISO 7599 for color, corrosion, and wear. When buyers require comparative corrosion data, neutral salt-spray per ASTM B117 can benchmark finishes (interpret hours in context of real environment). Keep drawings lean with ISO 2768 general tolerances and apply GD\&T only where fit/function demand it.

At Prime (China)—founded 1993, ISO-certified, 10 production lines—I weigh raw stock cost, cycle time, finish thickness, and total shipment mass. If weight isn’t mission-critical, steel usually wins on cost-per-strength1. If mass or thermal roles2 matter, aluminum can be cheaper at the system level even with anodizing.

Upload your drawing for 24-hour DFM advice1 and a steel-vs-aluminum cost model2 including finishing and freight.

Practical checkpoints buyers should verify

- Quantify mass impact on freight, ergonomics, and fixture size.

- Compare machinability1: feeds/speeds, chip control, tool life, and coolant plan.

- Lock coatings2: powder/zinc for steel; Type II/III anodize per ISO 7599 for aluminum.

Quality & packaging notes buyers care about

- Steel: blocked pallets, steel strapping1, edge boards, VCI paper for sea freight.

- Aluminum: PE film, foam partitions, and desiccant; avoid metal-to-metal rub.

- Request FAI + CMM2 on first lot to lock CTQ dimensions and acceptance bands.

| Factor | Option A (Steel) | Option B (Aluminum) | What it means for cost/lead time |

|---|---|---|---|

| Material/Grade | AISI 1018/1045/4140; 304/316 | 6061-T6, 6082-T6, 7075-T6 | Steel cheaper/kg; Al lighter |

| Strength/Hardness1 | \~400–>900 MPa; HRC 15–50 | \~150–560 MPa; HB 60–150 | Steel for heavy loads/wear |

| Corrosion Resistance2 | Paint/zinc; stainless excels | Natural oxide; anodize per ISO 7599 | Finish choice drives cost |

| Tolerance Feasibility | Stiffer, holds thin walls | Risk of deflection/burr | Steel favors tight fits |

| Surface Finish | Powder coat 60–90 µm typical | Anodize 10–25 µm (Type II), 25–70 µm (Type III) | Extra steps add days |

| Testing/Reports | CMM, hardness, ASTM B117 | CMM, conductivity, ASTM B117 | Define pass/fail early |

Steel vs. Aluminum – Key Differences & Applications Explained?

Picking by habit wastes money1 and time.

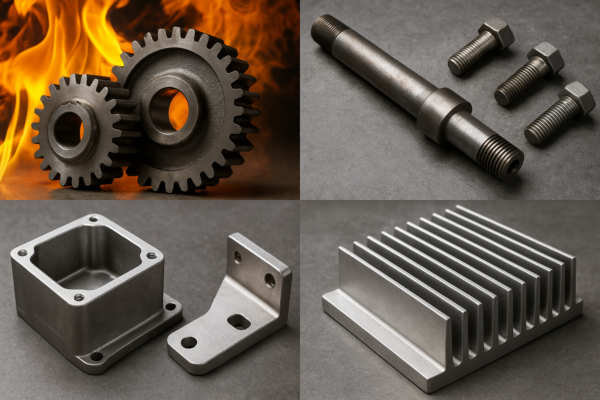

Steel offers superior wear, fatigue, and high-temperature capability; aluminum offers low weight and high thermal conductivity1. Use steel for gears, shafts, fixtures, and welded structures; use aluminum for housings, brackets, heat-sinks, and lightweight frames. Manage galvanic couples2 in mixed-metal assemblies and specify finishes to match the real environment.

Applications decide winners. Aluminum’s thermal conductivity (\~150–230 W/m·K) exceeds carbon steel’s (\~45–60 W/m·K), making it ideal for heat-sinks and electronic housings. However, several aluminum alloys lose strength more rapidly above \~150–200 °C, so under-hood brackets or oven-adjacent tooling often favor steel for stiffness and retention of properties (see ASM Handbook for behavior at temperature). For fatigue-sensitive or abrasive contacts (rollers, gears, cams), steel’s endurance limit and wear response are advantageous. In mixed assemblies, control galvanic corrosion: aluminum coupled to steel or stainless in the presence of electrolytes can corrode. Break the galvanic path with isolating washers, compatible coatings, and sealants; reference NASA’s galvanic series guidance for design practice (NASA Corrosion).

Finishing strategy should be explicit. For cosmetic aluminum, specify ISO 7599 Type II anodize (10–25 µm) for color/corrosion; choose Type III (25–70 µm) for wear-critical sliding fits. For steels, powder coating typically targets 60–90 µm; heavier-duty systems can exceed 100 µm. If stainless is selected, passivation per ASTM A967 removes free iron and restores corrosion resistance after machining. Keep drawings concise with ISO 2768 and use GD\&T only where function demands (holes: H7; shafts: appropriate g6/k6 as needed). At Prime, I also recommend a lightweight DFM pass—adding fillets ≥1 mm, ribbing thin walls, and ensuring tool access—to lower cycle time and scrap.

Send your drawing for an application-matched recommendation1 and a 24-hour quote2 including finish, inspection, and packaging.

Practical checkpoints buyers should verify

- Environment: temperature, salt, UV, and cleaning chemicals1 across service life.

- Loads: static vs cyclic; impact vs abrasion; safety factors by duty cycle2.

- Mixed metals: isolate fasteners, align finishes, and seal joints.

Quality & packaging notes buyers care about

- Steel: mark grade and heat lot for traceability1; apply VCI and humidity cards.

- Aluminum: protect anodized faces with film; pack by cells to avoid scratching.

- Define acceptance: CMM plan2, Ra targets, and salt-spray hours if required.

| Factor | Steel | Aluminum | Cost/Lead Time Impact |

|---|---|---|---|

| Density | \~7.85 g/cm³ | \~2.70 g/cm³ | Aluminum cuts freight/handling |

| Machinability1 | Moderate; tool wear | Fast; low cutting forces | Al shortens cycle time |

| Thermal Conductivity2 | \~45–60 W/m·K | \~150–230 W/m·K | Al for heat-sinks/enclosures |

| High-Temp Behavior | Retains strength better | Faster property drop ≥150–200 °C | Steel for hot zones |

| Fatigue/Wear | High endurance; hardenable | Lower; needs hard coat | Steel for gears/rollers |

| Galvanic Risk | With Al when wet | With steel fasteners | Design isolation/barriers |

Aluminum vs. Steel: Strength, Weight, and Applications Compared?

Weight savings can be real—or a mirage—without lifecycle math1.

Aluminum1 weighs \~⅓ of steel2, often machines faster, and resists general corrosion; steel2 delivers higher tensile/fatigue strength and better high-temperature stability. Use aluminum when mass or thermal roles dominate; choose steel2 when loads, wear, or heat are severe. Confirm with measurable finishes, realistic tolerances, and standards-based tests.

Start with numbers and context. Aluminum density (\~2.70 g/cm³) versus steel (\~7.85 g/cm³) means a like-volume bracket is roughly two-thirds lighter—improving ergonomics and freight. Yet common aluminum tempers (6061-T6 ≈ 310 MPa; 7075-T6 ≈ 510–570 MPa) still trail many alloy steels used for shafts, gears, and structural fixtures (MatWeb). Where shock, abrasive sliding, or elevated temperatures occur, steel’s modulus and wear response justify the mass penalty. For cosmetics and corrosion, specify anodizing per ISO 7599: Type II (10–25 µm) for color/general corrosion; Type III (25–70 µm) for wear. Steels take powder coat typically at 60–90 µm; zinc plating adds sacrificial protection but needs post-plate baking when hydrogen embrittlement risk exists on high-strength grades (consult plating specs). Validate corrosion protection with ASTM B117 (use as a comparative screen, not a life predictor). If stainless is chosen, require post-machining passivation per ASTM A967. Keep drawings efficient with ISO 2768 and reserve GD\&T for critical datums.

Manufacturing details matter: aluminum can smear and form a built-up edge—use sharp tools, proper chip load, and high-lubricity coolants. Steel benefits from coated carbides, flood coolant, and staged depths to control work-hardening. If you must mix metals, mitigate galvanic couples (isolate fasteners, add sealants, design drainage) following NASA guidance. At Prime (China), I combine DFM, fixture planning, and packaging engineering (ISTA-style drop considerations) to avoid scrap and transit damage before they start.

Send your drawing to Prime (China)—founded 1993, ISO-certified1, 10 production lines—for a 24-hour DFM2, FAI/CMM plan, and firm quote with packaging spec.

Practical checkpoints buyers should verify

- Weight vs load: simulate real duty cycles before locking material.

- Finish durability1: anodize thickness vs wear; powder-coat edge coverage.

- Inspection2: define GD\&T, gauges, and acceptance criteria up front.

Quality & packaging notes buyers care about

- Aluminum: protect sealed anodized surfaces1; avoid abrasive rub during transit.

- Steel: light oil or VCI wrap; humidity indicators for ocean freight2.

- Carton/pallet labels: alloy, hardness, PO, and piece count for fast incoming QC.

| Factor | Steel | Aluminum | Impact on Buyer |

|---|---|---|---|

| Tensile Strength1 | Often > 600 MPa (alloy steels) | \~150–560 MPa (by alloy/temper) | Select per peak loads |

| Weight | Higher; robust | Lower; ergonomic | Affects freight & assembly |

| Heat Resistance | Superior | Drops faster ≥150–200 °C | Choose per duty cycle |

| Finish Path | Powder coat, zinc; passivate (SS) | Anodize Type II/III per ISO 7599 | Drives lead times |

| Thermal Conductivity2 | \~45–60 W/m·K | \~150–230 W/m·K | Aluminum for cooling roles |

| Lifecycle | Long wear; strong threads | Light; corrosion-tolerant | Compare total cost of ownership |

Conclusion

Choose steel for high loads, wear, and heat1; choose aluminum for weight and thermal roles2—upload your drawing for a 24-hour DFM review and firm quote now.

-

Explore this link to understand the best materials for high-stress environments, ensuring optimal performance and durability. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the advantages of aluminum in thermal roles, which can help you make informed decisions for your projects. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩