How to select reliable metal parts custom manufacturers? Professional experience sharing of Prime Custom Parts?

You likely worry about delays, defects, and unclear quotes. I do too when I buy. So I built a clear selection method that works in real factories and busy supply chains.

A reliable manufacturer proves control with data, certification, and delivery discipline. I verify live SPC, clean GD\&T, and packaging strength against global lanes. I also cross-check standards like ISO 9001 and ASME Y14.5 to keep drawings and audits aligned. ([International Organization for Standardization][1], [American Society of Mechanical Engineers][2])

I write in simple words. I share my checklists since 1993. Then you can audit faster, choose smarter, and negotiate with facts, not hope.

Based on the experience of 1993, how do you assess a manufacturer’s quality control capability?

Many teams trust claims, not proof. I did that early on. I paid for rework and returns. So I changed my approach. Now I audit the system, the data, and the line in motion.

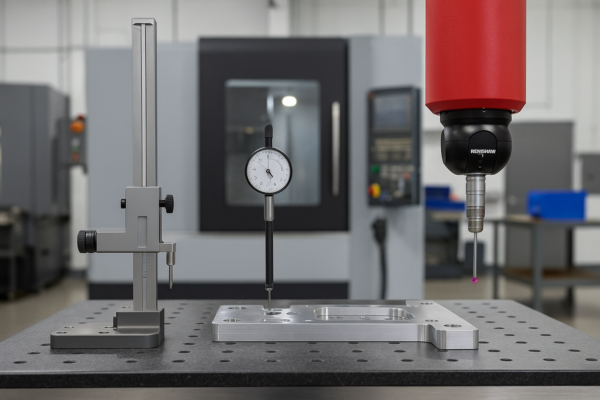

I confirm SPC for critical features, verify gauge trust with MSA, and request recent nonconformance logs. I also watch operators use gauges and probes on live parts. For context, see practical explainers on SPC, MSA, and NIST’s handbook on control charts. ([Wikipedia][3], [NIST][4])

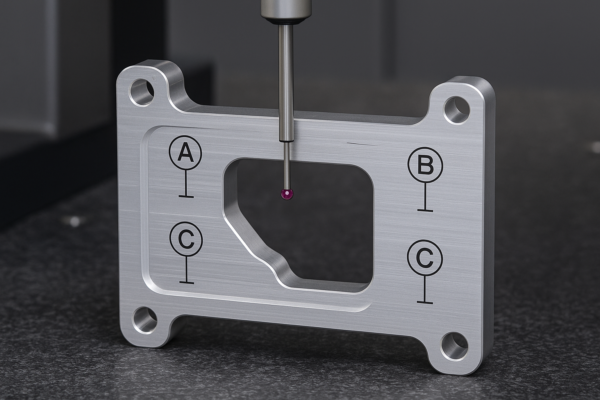

I spot problems by following the traveler with the part. I match the print to fixtures. I check whether GD\&T datums track to inspection plans per ASME Y14.5. I want clear logs for Cp, Cpk, and fixes. If I see guessing or missing charts, I walk away. For quick signal checks, I use simple go/no-go methods and save CMM for sign-off. You can skim a plain overview of a go/no-go gauge and a CMM first. ([American Society of Mechanical Engineers][2], [Wikipedia][5])

Dive-Deeper: a field-tested QC audit you can copy today

I start with incoming material. I confirm mill certs, hardness, and surface. Then I walk the press, mill, or weld cell. I watch a real setup. I ask the operator to run three parts and measure. I compare readings to control charts. I want clean, recent SPC with Cpk ≥ 1.33 on stable runs. I match calibration stickers and due dates. I photograph gauges and fixtures with IDs visible. I keep copies of first-article reports tied to datums and feature numbers from ASME Y14.5. ([American Society of Mechanical Engineers][2])

I next open the nonconformance log. I ask for the last three issues. I want root causes, containment, and prevention. If reports look thin, the system likely lacks depth. I also check MSA. I look for gage R\&R values under 10%. I confirm that the team repeats studies for new features. When gauges drift, good shops react fast. The NIST e-Handbook explains practical chart choices and limits, while Investopedia’s three-sigma primer helps non-engineers follow control limits. ([NIST][6], [Investopedia][7])

Finally, I review packaging and labeling. I ask for ISTA-style tests and VCI plans. I scan HS codes and language on labels. If the shipper cannot explain the crate, I get nervous. Clear packs protect months of work. I reference ISTA overviews and DHL or FedEx guides to align expectations early. See ISTA 1A, DHL packaging advice, and FedEx packing. ([ista.org][8], [DHL][9], [FedEx][10])

| QC Artifact | What I look for | Why it matters | Helpful source |

|---|---|---|---|

| SPC charts | Date, trend, Cpk ≥ 1.33 | Predictable output | SPC basics ([Wikipedia][3]) |

| MSA (gage R\&R) | %StudyVar ≤ 10% | Trust in readings | MSA ([Wikipedia][11]) |

| First Article | Features tied to datums | Setup locked | ASME Y14.5 ([American Society of Mechanical Engineers][2]) |

| Calibration | Tags and due dates | Stop drift | Mitutoyo CMM ([Mitutoyo][12]) |

| Pack plan | VCI, ISTA logic | Survive transit | ISTA 1A ([ista.org][8]) |

How important is ISO certification? What are the key criteria for selecting a custom manufacturer?

ISO alone does not guarantee results. But it sets a useful floor. I treat certification as the first filter. Then I score process fit, metrology depth, packaging rigor, and delivery control.

ISO 9001 proves a quality system exists with audits, document control, and training. Your criteria confirm it works for your drawings, volumes, and timelines. Read the official ISO 9001 overview to align questions with clauses. ([International Organization for Standardization][1])

I verify the certificate and audit cycle. I ask for the last audit summary. I also check process fit. Do they run servo presses and progressive dies for scale? Do they run five-axis CNC with probing for complex parts? Can they qualify welds by code? Good weld shops hold AWS D1.1 or align to ISO 15614-1. I confirm this before I trust structural assemblies. ([pubs.aws.org][13])

I also rate packaging and trade readiness. Strong exports follow Incoterms® 2020 and label by HS codes. Clean cartons and stable lanes keep promises real. ([ICC – International Chamber of Commerce][14], [World Customs Organization][15])

Dive-Deeper: a practical selection scorecard I use with buyers

I keep the scorecard simple. I divide it into system, capability, and logistics. I assign weights based on risk. Then I decide with my team. If a vendor fails critical items, I exit early. Otherwise, I run a pilot order under tight control before I scale. This stops schedule pain later.

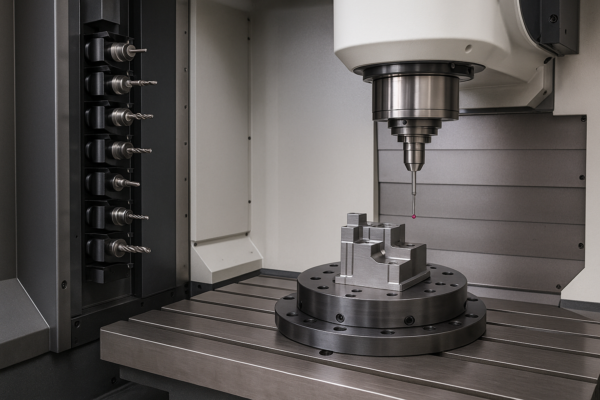

I recommend verifying basic standards first. Confirm ISO 9001 status, review a process map, and check internal audits. Next, validate capability. For stamping, ask about die maintenance and in-die options like Pronic in-die tapping. For CNC, check probing based on Renishaw OMP60 and zero-point pallets like SCHUNK VERO-S. For welding, ask for WPS, PQR, and welder stamps against ISO 15614-1 or AWS D1.1. Finally, test logistics with ISTA 1A and label prep per DHL or FedEx guides. ([International Organization for Standardization][1], [ista.org][8], [DHL][9], [FedEx][10], [schunk.com][16], [Renishaw][17], [pubs.aws.org][13])

| Criterion | Evidence I want | Good sign | Example link |

|---|---|---|---|

| Certification | Valid ISO 9001 with audits | Tracked actions | ISO 9001 ([International Organization for Standardization][1]) |

| Stamping scale | Servo press + die sensors | Low burr, high Cpk | AIDA ([Renishaw][17]) |

| CNC flexibility | Probing + pallets | Fast changeovers | Renishaw OMP60 ([Renishaw][17]) |

| Welding depth | WPS/PQR to code | Audit ready | ISO 15614-1 ([pubs.aws.org][13]) |

| Packaging | VCI + ISTA logic | Fewer claims | ZERUST ([zerust.com][18]) |

| Trade | Incoterms + HS | Clear risk split | ICC / WCO ([ICC – International Chamber of Commerce][14], [World Customs Organization][15]) |

Fast delivery and flexible batching: how manufacturers balance efficiency and customization?

You want speed and customization together. Many shops force a trade. I refuse that. I build cells that change fast and cut right the first time.

I cut setup with SMED ideas, zero-point pallets, adaptive toolpaths, and spindle probing. I stage common alloys and hold buffer capacity for rush orders. If you need a primer, scan SMED, VERO-S pallets, Fusion Adaptive Clearing, and Renishaw OMP60. ([Wikipedia][19], [schunk.com][16], [Renishaw][17])

I also remove waste from drawings. I set functional tolerances only where performance demands it. I thicken walls and increase radii for stiff cuts. Then I mask threads before anodize. For simple design tips, I still point engineers to Protolabs machining toolkit and the Xometry CNC guide.

Dive-Deeper: a fast-lane playbook that protects both speed and quality

I plan cells before parts. I standardize tool holders and stick-out. I lock tool numbers in the CAM library of Autodesk Fusion. I pre-program macros for probing and offsets using Renishaw routines. I mount VERO-S pallets for five-minute changeovers. Then I rough with Adaptive Clearing to keep chip load constant. I finish with safe stepovers to hit surface targets. I validate with CMM before pack. I cut ECO pain since I reuse fixtures and tools. ([Renishaw][17], [schunk.com][16])

Next, I stage common materials like 6061-T6, 7075-T6, 304, 316L, and ductile iron. I choose coatings instead of prestige alloys when smart. For aluminum, I prefer anodizing. For steel, I often apply electroless nickel. For stainless, I run passivation. I validate corrosion with ASTM B117 when needed. ([Wikipedia][20], [zh-cn.q-lab.com][21])

Finally, I protect transit. I use ZERUST VCI, tilt labels like TiltWatch XTR, and cartons aligned to ISTA 1A. I book carriers early and send photo packs. Then I track exceptions fast. So orders land clean and on time. ([zerust.com][22], [shop.spotsee.io][23], [ista.org][24])

| Lever | My action | Why it helps | Reference |

|---|---|---|---|

| SMED | Pre-stage tools and pallets | Minutes, not hours, for changeover | SMED ([Wikipedia][19]) |

| Probing | Auto offsets and checks | First-piece right, less scrap | Renishaw OMP60 ([Renishaw][17]) |

| Toolpaths | Adaptive roughing | Constant load, longer tool life | Fusion Adaptive |

| Workholding | Zero-point pallets | Repeatable swaps | VERO-S ([schunk.com][16]) |

| Packaging | VCI + tilt labels | Survive long lanes | ZERUST / TiltWatch ([zerust.com][18], [shop.spotsee.io][25]) |

Customer Success Stories: How can you make your products more competitive by customizing them?

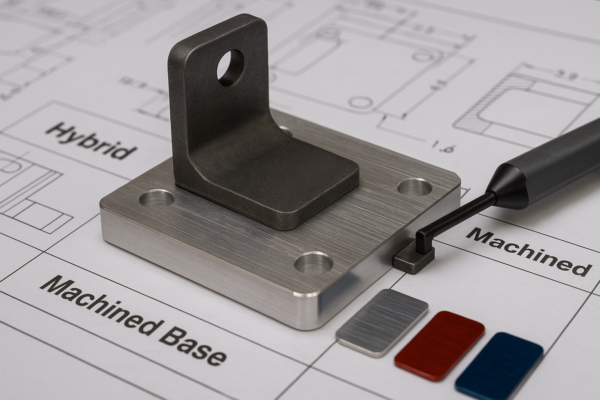

Customization should raise performance or cut cost. I push for both. I also protect launch dates with lean cells and clear packaging plans.

Smart customization reduces part count, eliminates rework, and speeds assembly. Clean drawings, right materials, and fair tolerances keep price competitive and stable. I check simple references like sheet metal basics and practical DFM machining toolkits to align teams fast. ([Wikipedia][26])

Story 1: terminals and covers for automation gear. The buyer used laser blanks and hand deburr. Burrs returned and labor rose. I moved to progressive dies and in-die tapping from Pronic. I added poka-yoke and clear checks based on go/no-go. Burr height stabilized. Piece price fell by double digits. Lead time improved since we removed a secondary step. ([Renishaw][17], [Wikipedia][5])

Story 2: generator bracket for desert service. The team needed strength and fast assembly. I cast a ductile iron base and welded stainless tie-ins. I qualified welds to ISO 15614-1 and inspected with ultrasonic testing. I finished with e-coat per electrophoretic deposition. Failures vanished. Assembly time fell by 30%. ([pubs.aws.org][13], [Wikipedia][27])

Story 3: anodized aluminum housings with premium finish. The drawing called tight flatness everywhere. Cycle time exploded. I focused tolerance only on seals. I switched to 6061-T6 and Type II clear anodizing. I masked threads and measured Ra. The finish improved and cost dropped. The product beat rivals to shelf. For alloy basics, compare 6061 and 7075. ([Wikipedia][20])

Dive-Deeper: a simple recipe to turn customization into a market edge

I start with real failure modes. I ask where the part fails first. Is it yield, wear, fatigue, or corrosion? I align function to tolerance and finish. I prefer 6061-T6 for most brackets and swap to 7075-T6 only when strength drives value. I choose 17-4PH for strength with corrosion resistance and 316L for aggressive media. I keep references handy for 6061, 7075, 17-4PH, and 316L to help non-specialists follow along. ([Wikipedia][28])

Then I reduce part count. I combine stamped blanks with CNC finish cuts and add weldments only when interfaces vary. I assign WPS and PQR by code and record heat input for traceability per AWS D1.1 or ISO 15614-1. Next, I pick finishes smartly. I use anodizing for aluminum, electroless nickel for steel details, and passivation for stainless. I validate with salt fog under ASTM B117 if the spec calls for it. Finally, I protect transit with ZERUST films and TiltWatch labels, following ISTA logic. ([pubs.aws.org][13], [ICC – International Chamber of Commerce][14], [Wikipedia][20], [zh-cn.q-lab.com][21], [zerust.com][22], [shop.spotsee.io][23], [ista.org][24])

| Use case | My preferred path | Why it wins | Useful link |

|---|---|---|---|

| Strong but light bracket | 6061 + Type II anodize | Machines fast, finish looks premium | 6061 |

| Ultra strength | 7075 + hardcoat | High strength; protect from corrosion | 7075 |

| Strength + corrosion | 17-4PH H900 | Heat treatable and stable | 17-4 |

| Marine or food grade | 316L + passivation | Chloride resistance and clean surface | 316L |

| Structural frame | Ductile iron + weld | Tough and cost effective | Ductile iron |

Conclusion

Pick proof over promises; verify ISO, SPC, and logistics; demand DFM; then scale customization safely, quickly, and at fair cost.

I speak for Prime. I serve B2B wholesale only. I supply stamping parts, CNC parts, welding parts, casting parts, fasteners, and plastic parts. I run 10 production lines with ISO control. I export to North America, Europe, the Middle East, and Australia. I reply fast with clean quotes, SPC snapshots, and packing photos. Visit primecustomparts.com and email [email protected] for a free consultation, quick quote, and tailored plan. I commit to fast delivery and stable quality, order after order.

Search-friendly long-tails used naturally: custom stamping parts supplier, CNC parts precision machining, ISO-certified casting parts manufacturer, welding assemblies supplier, industrial fasteners wholesale China, plastic insert molding manufacturer, CNC aluminum 6061 anodized parts, 5-axis rapid prototype machining.