How to Select the Supplier of Precision Metal Casting Parts Recommended by Chinese Manufacturers with ISO Certification?

Finding a precision metal casting supplier1 is not easy. Delays, defects, and poor communication2 can all ruin your project.

Selecting an ISO-certified Chinese supplier1 protects your business. You get consistent quality, competitive pricing, and fast lead times. In this complete guide, I show you proven steps, selection criteria, and insider tips to help you avoid sourcing risks2.

Many buyers feel lost among so many online suppliers. After reading this article, you will understand which questions to ask, how to compare suppliers1, and why Prime stands out as a leading precision casting manufacturer2.

If you want quality, speed, and competitive prices1, your supplier choice2 is key. My experience with Prime proves you can have all three—when you know what to look for.

What Are the Main Types of Metal Casting Processes and How Do They Affect Quality?

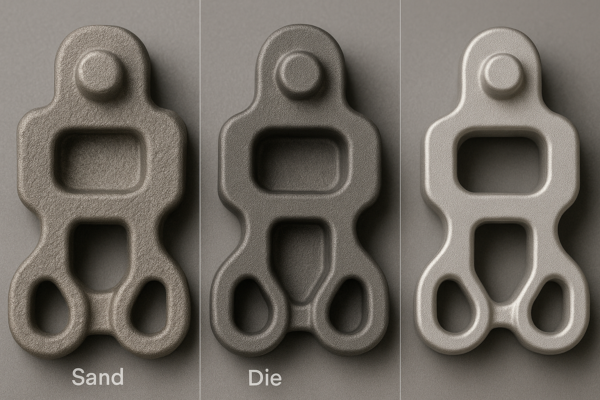

Choosing the wrong process increases costs and quality risks. Sand casting, die casting, and precision casting1 (investment casting) each offer unique advantages.

Sand casting is best for large or simple shapes, offering flexibility at a low cost. Die casting is ideal for high volumes and fine details, but requires high upfront tooling investment. Precision casting delivers1 the tightest tolerances, highest accuracy, and smoothest surface—perfect for critical applications.

I learned over the years that you must match process to your design and order size1. My clients rely on my honest advice, which always starts with the right process2.

Compare Key Casting Processes for Industrial Applications

| Process | Best For | Tolerance & Finish | Cost Level | Typical Orders |

|---|---|---|---|---|

| Sand Casting | Large/simple parts, prototypes | Medium/rough | Low | Small-medium volumes |

| Die Casting1 | Complex, detailed, small/medium parts | High/very smooth | Medium-high | Medium-large volumes |

| Precision Casting2 | Complex, high-value, tight-tolerance parts | Highest/smoothest | Medium | Small-large volumes |

How to Select the Right Casting Process

- Sand casting: ideal for rapid prototyping1 and low-volume, large-sized orders.

- Die casting: perfect for electronics, auto parts, and mass production2.

- Precision casting: essential for aerospace, medical, and critical machinery.

When I source parts, I always ask suppliers for real project photos and process certificates1. Prime provides detailed case studies2 and clear process capability statements with every quote.

Why Is ISO 9001 Certification and Quality Control So Important in Precision Casting?

You risk delays and losses without a certified supplier1. ISO 90012 is not just a certificate; it’s proof your supplier has strict procedures for every step.

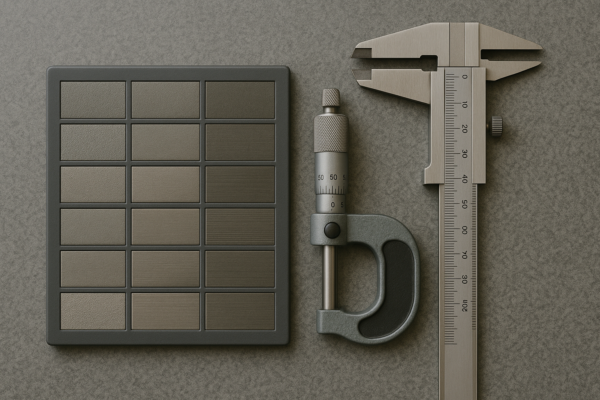

ISO 9001-certified suppliers1 track every production step, from material to final inspection. They use standard measurement tools and deliver full reports with every order. Always request current certificates, test reports, and product traceability documents2 before placing orders.

Many importers learn this lesson after a shipment fails inspection. I avoid this by only working with ISO-certified suppliers. Prime always shares their up-to-date certificate and sample QC records1 before any order.

Quality Standards to Demand from Your Precision Casting Supplier

| Quality Standard | What It Means | Why It Matters |

|---|---|---|

| ISO 90011 | International QC management system | Stable, repeatable quality |

| Surface Roughness | Measured by Ra or Rz values | Ensures appearance, fit |

| Dimensional Tolerance | ISO 2768, ISO 8062, per your print | Critical for assembly |

| Material Certification2 | 100% test report, heat number trace | Avoids fake or mixed alloys |

| PPAP, FAI, CPK | Automotive, medical approval tools | Advanced validation, proof |

How Prime Delivers Consistent Quality

Prime’s ISO 9001-certified team1 uses advanced metrology2 for every batch. Each project comes with inspection photos, digital test results, and traceable batch numbers.

When my client needed ultra-smooth turbine parts, Prime provided both Ra 1.6 surface finish1 and a full CMM inspection report2. Our project went smoothly and the client renewed their contract.

What Are the Differences Between Aluminum, Zinc, and Stainless Steel Castings?

Material choice1 decides part performance and lifetime cost. Each alloy has its own strengths and limitations.

Aluminum alloy1 is lightweight, corrosion-resistant, and strong—ideal for transport and high-tech parts. Zinc alloy2 is easy to shape, perfect for fine detail at low cost, but less strong. Stainless steel offers unbeatable strength and rust resistance for medical and marine use, but is heavier and pricier.

Prime helps buyers choose the right alloy for every application1. I always check for real material test certificates2 with every order.

Detailed Comparison of Common Casting Materials

| Material | Advantages | Limitations | Applications |

|---|---|---|---|

| Aluminum Alloy1 | Light, strong, anti-corrosion | Scratches, not for all loads | Autos, aircraft, machinery |

| Zinc Alloy | Very detailed, cheap, low temp melt | Not as strong, lower temp | Electronics, housings, toys |

| Stainless Steel2 | Corrosion-proof, strong, durable | Heavy, expensive | Medical, marine, outdoor |

How to Pick the Right Alloy

- Aluminum for weight-sensitive parts.

- Zinc for detailed, low-cost, high-volume parts.

- Stainless steel for critical, harsh environments.1

Prime always provides a full chemical test report1 and heat number2 for each shipment. I compare these to customer specs before accepting delivery.

Why Is Packaging and Global Logistics Critical for Safe, On-Time Delivery?

You can lose money and customers if your goods arrive damaged or late.

A reliable supplier1 uses robust packaging, tracks shipments, and helps you clear customs. Prime uses custom crates2, anti-corrosion materials, and export labels to protect every order. Orders ship with photos, tracking numbers, and insurance—so you never worry about loss or delay.

I always ask for drop-test photos1 and shipping details. Prime’s attention to packaging detail2 means my clients get perfect goods, every time.

Prime’s Export Logistics Process

| Step | What Prime Does for You |

|---|---|

| Custom Packaging1 | Prevents damage during transport |

| Clear Labeling | Eases customs, speeds receipt |

| Shipping Insurance2 | Protects against loss, delay |

| Tracking Provided | Allows real-time order updates |

| Fast Global Freight | Air and sea to major world ports |

How to Avoid Shipping Problems

- Always request packaging photos1 before shipment.

- Confirm customs labels and documentation2.

- Use suppliers with real export experience.

Prime ships to North America, Europe, the Middle East, Australia, and beyond.

Why Is Prime the Trusted Choice for OEM Precision Casting Projects?

You need fast feedback1, full customization2, and a partner who supports your brand.

Prime delivers instant quotes1, rapid DFM analysis2, and flexible OEM services. We handle complex logos, special packaging, and tight timelines with 10 production lines and a proven engineering team. Our English-speaking project managers keep you updated every step.

I have worked with many suppliers. Only Prime consistently delivers custom projects1 on time, with no language issues and clear, friendly communication2.

What Makes Prime Stand Out?

| Prime Benefit | What You Get | Customer Example |

|---|---|---|

| 24h Quotation | Faster project launch | USA HVAC client, urgent RFQ |

| Custom Branding & Packaging | Unique market presence | Custom logo, EU client |

| High Capacity Production1 | Fewer supply interruptions | 30,000+ parts/week, UK buyer |

| Strict QC, Zero Defects2 | Stable quality, happy clients | 99.7% pass rate, 3 years |

| Proactive Communication | Zero surprises, always informed | Project status reports, photos |

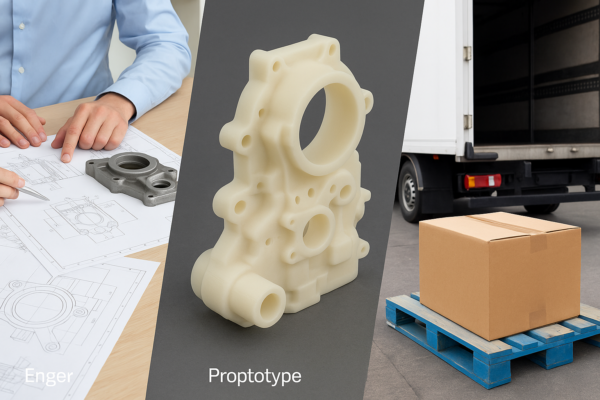

Prime’s Full-Service Process: From Quote to Delivery

Success starts with clear steps and reliable communication.

Prime supports you at every stage—from design review1 and fast sampling to mass production, inspection, and international logistics2. We give you peace of mind, so you can focus on your core business.

Prime’s Sourcing and Fulfillment Steps

- Send inquiry or drawing to [email protected] or via https://primecustomparts.com/.

- Receive technical review and DFM advice within 24 hours.

- Get free samples and process validation as needed.

- Approve mass production and inspection plan with project manager.

- Track shipment with photos and live updates until goods arrive.

Frequently Asked Questions About Precision Metal Casting Sourcing

1. What is the minimum order quantity for custom casting parts1?

Prime accepts MOQs as low as 500 pieces for new projects, with flexible batch sizes for repeat orders.

2. How can I check material quality before mass production?

Request a material certificate and a test sample2. Prime offers free pre-production samples and full lab reports.

3. Can Prime handle urgent or multi-part orders?

Yes. With 10 lines and robust scheduling, urgent and multi-type orders1 are routine.

4. What support is available for design changes?

Prime’s engineers provide DFM and design change feedback within 24 hours, with 3D modeling and rapid sampling.

5. Which industries does Prime serve?

Prime supplies auto, electronics, energy, machinery, construction, medical, and marine industries worldwide.

6. How does Prime ensure fast, safe delivery?

We use top global logistics partners1, robust packaging, tracking, and insurance on every shipment.

7. What if I have a quality claim?

Contact us within 7 days of receipt at [email protected]. Our team will solve the issue and offer replacements or refunds as needed.

8. How do I start my project with Prime?

Send your drawings, specs, or ideas to https://primecustomparts.com/ or email [email protected] for a free review and fast quote.

Conclusion

Prime guarantees ISO-certified quality, rapid feedback, and reliable delivery for every order. Visit https://primecustomparts.com/ or email [email protected] now for a free consultation, expert quotation, and tailor-made solutions. Secure your supply chain with confidence—work with Prime for your next precision casting project.

-

Learn about the advantages of partnering with global logistics providers for efficient supply chain management. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Exploring material quality checks ensures your products meet standards before full production. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩