Innovations in Plastic Parts Manufacturing: Trends and Techniques in 2025

Introduction

The plastic manufacturing industry has undergone significant transformation in recent years, driven by technological innovation, environmental concerns, and evolving market demands. As we navigate through 2025, manufacturers face increasing pressure to deliver high-quality plastic components that not only meet stringent performance requirements but also address sustainability challenges. The convergence of digital technologies, advanced materials science, and automation has created unprecedented opportunities for innovation in this sector.

For engineering professionals and procurement specialists in the plastic parts manufacturing industry, staying abreast of these developments is no longer optional—it’s essential for maintaining competitiveness in a rapidly evolving landscape. The ability to leverage cutting-edge technologies while optimizing traditional processes has become a key differentiator for successful manufacturers.

This article explores the latest innovations shaping plastic parts manufacturing in 2025, examining advancements in manufacturing processes, material selection strategies, design considerations, and quality control methodologies. By understanding these trends and techniques, industry professionals can make informed decisions that enhance efficiency, promote sustainability, and improve product performance.

From bio-based plastics and smart manufacturing to micro-precision molding and advanced quality control systems, we’ll provide a comprehensive overview of the tools and approaches that are defining excellence in plastic parts production today. Whether you’re an engineer seeking to optimize your manufacturing processes or a procurement specialist evaluating supplier capabilities, this guide offers valuable insights into the current state and future direction of plastic parts manufacturing.

Latest Technological Advancements in Plastic Manufacturing (2025)

The landscape of plastic manufacturing has evolved dramatically in 2025, with several key innovations reshaping how parts are designed, produced, and recycled. These advancements are not merely incremental improvements but represent paradigm shifts that address longstanding industry challenges while opening new possibilities for product development.

Advanced Materials and Bio-Based Plastics

One of the most significant developments in 2025 is the widespread adoption of advanced and bio-based materials. Environmental concerns and regulatory pressures have accelerated the transition away from conventional petroleum-based plastics toward more sustainable alternatives.

Biodegradable polymers derived from renewable resources have moved beyond niche applications to become mainstream options for many products. According to StartUs Insights’ 2025 polymer industry analysis, the global biopolymers market is projected to reach USD 52.33 billion by 2034, growing at a compound annual growth rate of 10.43% from 2025 to 2034 (StartUs Insights, 2025).

These materials not only reduce carbon footprint but also offer enhanced end-of-life options, including industrial composting and biodegradation in natural environments. Innovations in PLA (polylactic acid), PHA (polyhydroxyalkanoates), and cellulose-based polymers have significantly improved their mechanical properties and processing characteristics, making them viable alternatives for applications previously dominated by conventional plastics.

Simultaneously, high-performance polymers like PAEK (Polyaryletherketone) and reinforced thermoplastics have seen remarkable advancements. These materials provide exceptional strength, heat resistance, and chemical stability, enabling the production of durable components for demanding applications across automotive, aerospace, and electronics sectors. The integration of nanomaterials and specialized additives has further enhanced their performance characteristics, allowing manufacturers to meet increasingly stringent requirements while reducing material usage.

Smart and Functional Molding

The integration of smart features into molded parts represents another frontier in plastic manufacturing innovation. By embedding conductive fillers, sensors, or RFID tags during the molding process, manufacturers can now create components with enhanced capabilities such as conductivity, data storage, or environmental sensing.

This trend toward "functional molding" has transformed traditional manufacturing approaches, enabling the production of parts that combine structural integrity with added functionalities. For example, medical devices now incorporate embedded sensors that monitor patient health parameters, while consumer electronics feature integrated circuit pathways molded directly into structural components.

The development of conductive polymers has been particularly noteworthy, with applications ranging from flexible electronics to electromagnetic interference (EMI) shielding. These materials combine the processability of conventional plastics with electrical conductivity properties previously available only in metals, opening new design possibilities across multiple industries.

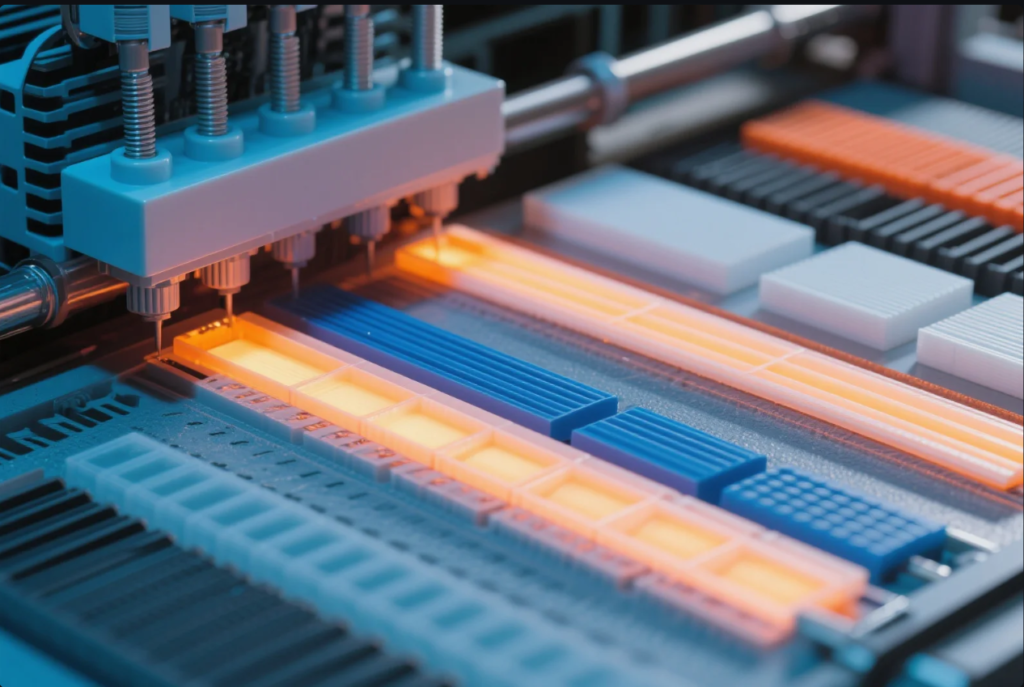

Automation and Industry 4.0 Integration

Automation has become the cornerstone of modern plastic manufacturing operations in 2025. The implementation of Industry 4.0 principles—characterized by interconnected systems, real-time data analytics, and artificial intelligence—has revolutionized production environments.

Advanced robotics systems now handle complex tasks throughout the manufacturing process, from material handling and mold setup to part removal and quality inspection. These systems operate with unprecedented precision and consistency, reducing cycle times while improving part quality and repeatability.

IoT-enabled sensors embedded throughout production lines continuously monitor critical parameters such as temperature, pressure, and flow rates. This data feeds into sophisticated analytics platforms that identify optimization opportunities and predict potential issues before they impact production. Machine learning algorithms automatically adjust processing parameters in real-time, compensating for variations in material properties or environmental conditions.

Digital twin technology has emerged as a powerful tool for process optimization, allowing engineers to create virtual replicas of physical manufacturing systems. These digital models enable comprehensive simulation and testing of process changes without disrupting actual production, significantly reducing development time and costs.

Micro and Precision Molding Innovations

Advances in microinjection molding have enabled the production of extremely small, intricate components with unprecedented precision. This technology has become crucial for industries such as medical devices, electronics, and micro-mechanics, where miniaturization continues to drive product development.

In 2025, manufacturers can reliably produce plastic parts with features measured in micrometers, achieving tolerances previously possible only with more expensive manufacturing methods. Innovations in tooling materials, including advanced ceramics and specialized steel alloys, have improved mold durability while enabling finer detail reproduction.

Micro-molding technologies now support multi-material applications, allowing the production of tiny components with different material properties in a single manufacturing step. This capability has proven particularly valuable for medical applications, where biocompatibility, sterilizability, and mechanical performance must be precisely balanced.

The integration of in-mold sensors and real-time monitoring systems has further enhanced precision molding capabilities, ensuring consistent quality even at microscopic scales. These systems detect and compensate for variations that would be imperceptible in conventional molding operations, maintaining tight tolerances across production runs.

Energy-Efficient and Eco-Friendly Processes

Sustainability has become a central focus in modern injection molding operations. Efficient machines, such as hybrid and all-electric presses, consume significantly less power than traditional hydraulic systems, reducing operational costs and environmental impact.

The industry has embraced closed-loop manufacturing principles, with material reclamation and recycling integrated directly into production processes. Advanced sorting technologies, including AI-powered optical systems and chemical marking techniques, have improved the quality of recycled materials, making them suitable for an expanding range of applications.

Chemical recycling methods have advanced significantly, enabling the breakdown of complex plastic waste into molecular building blocks that can be repolymerized into virgin-quality materials. This approach has proven particularly valuable for handling mixed plastic waste streams that were previously difficult to recycle effectively.

Water conservation technologies have also gained prominence, with cooling systems that minimize consumption and wastewater generation. Heat recovery systems capture and repurpose thermal energy from molding operations, further reducing the overall environmental footprint of plastic manufacturing facilities.

These eco-friendly initiatives not only meet regulatory requirements but also appeal to environmentally conscious consumers and clients, aligning economic and ecological benefits in ways that were challenging to achieve in previous years.

Common Manufacturing Processes: Evolution and Optimization

The foundation of plastic parts manufacturing continues to be built upon several established processes, each of which has seen significant evolution and optimization in 2025. These advancements have expanded capabilities, improved efficiency, and enhanced the quality of produced parts across various applications.

3D Printing Advancements

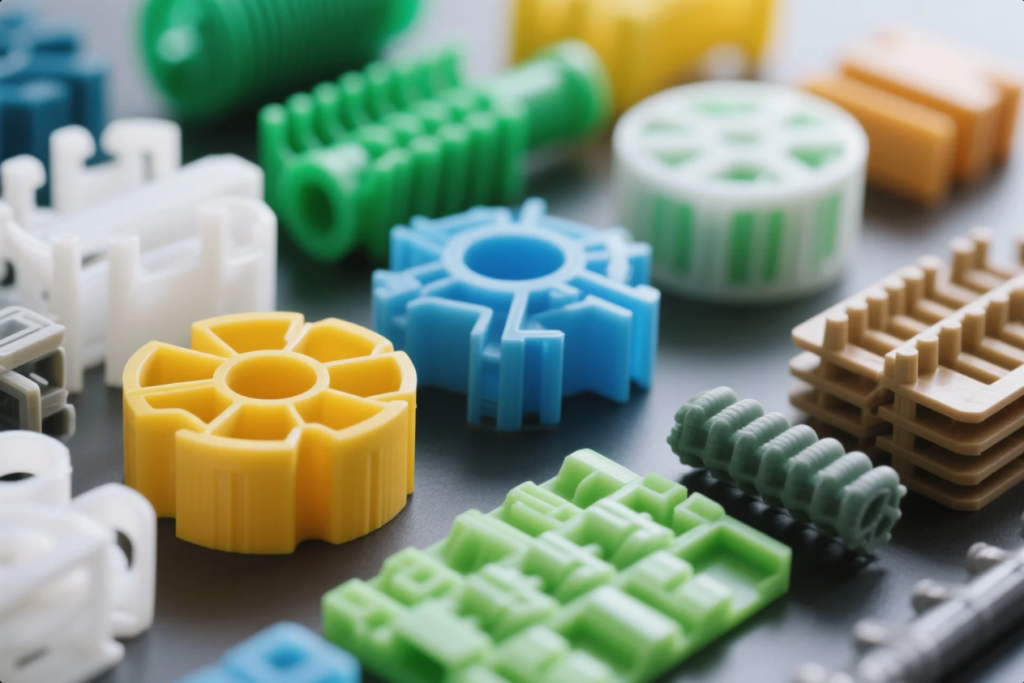

3D printing, or additive manufacturing, has undergone a remarkable transformation from a prototyping technology to a viable production method for end-use plastic parts. In 2025, several key developments have accelerated this transition:

High-speed continuous liquid interface production (CLIP) technologies have dramatically reduced print times, making 3D printing competitive with traditional methods for medium-volume production runs. These systems use oxygen-permeable membranes and precisely controlled light projection to form parts continuously rather than layer-by-layer, achieving speeds up to 100 times faster than conventional 3D printing methods.

Multi-material printing capabilities have expanded significantly, allowing single-print operations to incorporate materials with different mechanical, optical, and electrical properties. This advancement has enabled the production of complex functional assemblies without requiring post-print assembly steps.

Resolution and surface finish quality have improved to the point where many 3D-printed parts require minimal post-processing. Advanced resin formulations combined with precise light control systems can now achieve surface qualities comparable to injection molded parts in many applications.

Industrial-scale powder bed fusion systems have become more accessible and reliable, supporting production volumes previously considered impractical for additive manufacturing. These systems offer exceptional design freedom while maintaining consistent part quality across production runs.

For manufacturers, 3D printing now represents a versatile tool that complements traditional processes, particularly for complex geometries, customized products, and situations requiring rapid production without tooling investments.

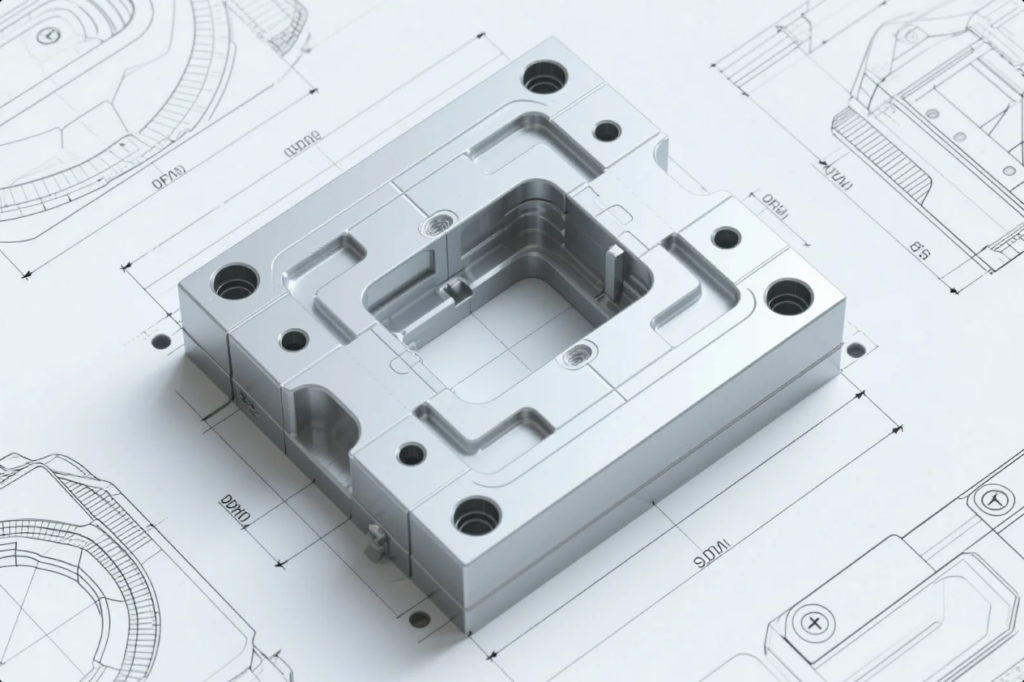

Injection Molding Innovations

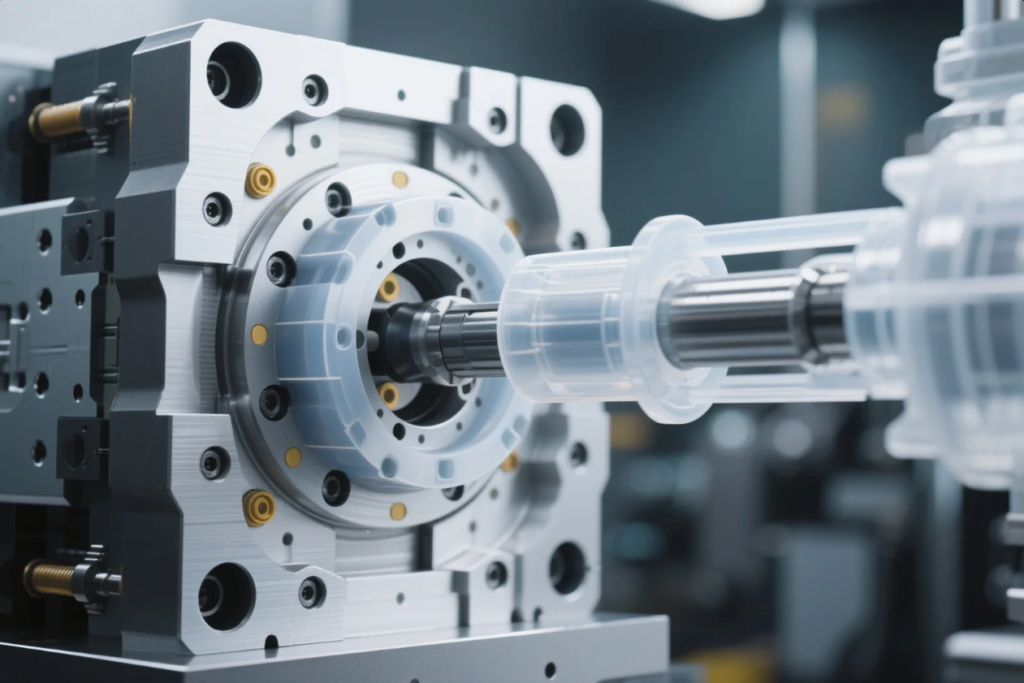

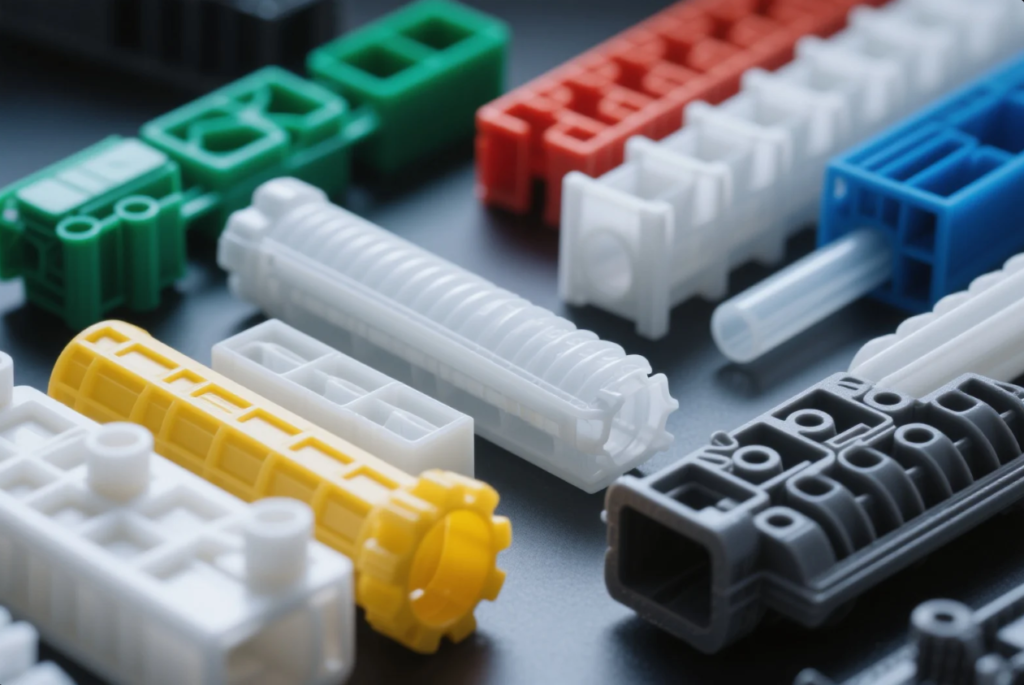

Injection molding remains the dominant process for high-volume plastic parts production, but it has evolved significantly to address contemporary challenges:

Multi-component injection molding has become increasingly sophisticated, allowing the production of complex assemblies in a single operation. Advanced systems can now incorporate up to six different materials in one part, eliminating assembly steps and creating previously impossible material combinations.

Conformal cooling channels, created through metal 3D printing, have revolutionized mold design. These optimized cooling pathways follow the contours of the part geometry, reducing cycle times by up to 40% while improving part quality and consistency. The integration of simulation software with mold design systems has automated the optimization of these cooling channels, making the technology more accessible to mid-sized manufacturers.

Thin-wall molding capabilities have advanced considerably, with specialized machines now capable of producing parts with wall thicknesses below 0.3mm. This development has been particularly valuable for electronics and medical device applications, where miniaturization continues to drive design requirements.

Gas-assisted and water-assisted injection molding techniques have been refined to create hollow sections and complex internal features without sink marks or warpage. These processes reduce material consumption while maintaining structural integrity, supporting lightweighting initiatives across multiple industries.

Predictive maintenance systems have significantly reduced unplanned downtime in injection molding operations. Machine learning algorithms analyze vibration patterns, power consumption, and other parameters to identify potential failures before they occur, allowing maintenance to be scheduled during planned production breaks.

Thermoforming Techniques

Thermoforming has experienced a renaissance in 2025, with technological advancements expanding its capabilities beyond traditional packaging applications:

Precision thermoforming systems now achieve tolerances comparable to injection molding for certain geometries, making the process viable for technical components in automotive, medical, and consumer electronics applications. Advanced temperature control systems and multi-stage forming processes enable the creation of complex features previously considered impossible with thermoforming.

In-mold labeling and decoration have been integrated directly into thermoforming lines, allowing high-quality graphics and functional elements to be incorporated during the forming process. This capability has reduced secondary operations while improving aesthetic quality and durability.

Automation has transformed thermoforming operations, with robotic systems handling material loading, part removal, and trimming operations. Vision systems ensure precise alignment and quality control, reducing labor costs and improving consistency.

Sustainable materials, including bio-based films and recycled content, have been optimized specifically for thermoforming applications. These materials maintain performance characteristics while reducing environmental impact, addressing growing market demand for eco-friendly packaging and products.

Extrusion Processing Updates

Extrusion technology has evolved to support increasingly complex profiles and enhanced material properties:

Multi-layer co-extrusion systems can now produce profiles with up to 15 distinct layers, each optimized for specific performance characteristics. This capability has proven particularly valuable for packaging applications requiring precise barrier properties and medical tubing with specialized surface characteristics.

Inline monitoring and control systems continuously adjust processing parameters based on real-time measurements of dimensions, surface quality, and material properties. These closed-loop systems maintain tight tolerances even when material characteristics vary, reducing scrap rates and improving consistency.

Advanced die designs, optimized through computational fluid dynamics simulations, have improved flow characteristics and reduced pressure requirements. These improvements have enabled higher production speeds while maintaining part quality and reducing energy consumption.

Post-extrusion processing has become more integrated, with operations such as cutting, forming, and assembly performed inline. This integration reduces handling requirements and work-in-process inventory, streamlining production flows and improving efficiency.

Blow Molding Developments

Blow molding has seen significant advancements in precision, efficiency, and material utilization:

Electric blow molding machines have largely replaced hydraulic systems, offering improved energy efficiency, cleaner operation, and more precise control. These systems achieve faster cycle times while reducing maintenance requirements and environmental impact.

Multi-layer and multi-material blow molding capabilities have expanded, enabling the production of containers with complex barrier properties and specialized functional characteristics. These advancements have been particularly important for pharmaceutical packaging, where protection requirements continue to become more stringent.

Lightweighting technologies have progressed significantly, with advanced process control and material formulations enabling wall thickness reductions of up to 30% compared to previous generations. These thinner walls maintain performance requirements while reducing material consumption and transportation costs.

In-mold labeling and decoration systems have become standard features on modern blow molding equipment, eliminating secondary operations and improving aesthetic quality. These systems precisely position labels or decorative elements before the blowing process, ensuring perfect integration with the finished container.

Rotational Molding Improvements

Rotational molding has traditionally been associated with large, relatively simple hollow parts, but recent innovations have expanded its capabilities:

Computerized process control systems have transformed rotational molding from an art to a science, with precise temperature monitoring and arm movement control ensuring consistent part quality. These systems automatically adjust heating and cooling cycles based on material characteristics and part geometry, reducing cycle times and improving efficiency.

Advanced mold designs incorporating removable inserts and complex cooling channels have enabled the production of more intricate geometries with improved surface finish. These developments have expanded rotational molding into applications previously served only by blow molding or injection molding.

Material advancements have addressed historical limitations in rotational molding, with new formulations offering improved flow characteristics, reduced cycle times, and enhanced mechanical properties. Specialized additives provide UV resistance, antimicrobial properties, and other functional characteristics without compromising processability.

Automation has been integrated throughout the rotational molding process, from material handling and loading to part removal and finishing operations. These systems have reduced labor requirements while improving safety and consistency.

Material Selection Strategies for 2025

Material selection has become increasingly complex in 2025, with manufacturers balancing performance requirements, sustainability goals, regulatory compliance, and economic considerations. Strategic approaches to material selection have evolved to address these multifaceted challenges.

High-Performance Polymers

The demand for high-performance polymers has accelerated across multiple industries, driven by requirements for greater durability, temperature resistance, and chemical stability:

Engineering-grade polymers such as PEEK (polyetheretherketone), PEI (polyetherimide), and PPSU (polyphenylsulfone) have seen expanded applications in aerospace, automotive, and medical sectors. These materials offer exceptional mechanical properties and thermal stability, allowing plastic components to replace metal in increasingly demanding environments.

Liquid crystal polymers (LCPs) have gained prominence in electronic applications, providing dimensional stability and flow characteristics ideal for miniaturized components with complex geometries. Their self-reinforcing molecular structure delivers exceptional strength without requiring additional reinforcement materials.

High-performance blends and alloys have been developed to provide customized property profiles that were previously unattainable with single-polymer systems. These sophisticated formulations combine the beneficial characteristics of multiple base polymers while mitigating their individual limitations.

Specialty additives have evolved to enhance specific properties without compromising overall performance. Advanced flame retardants, for example, now achieve required fire safety standards with minimal impact on mechanical properties and processability, addressing historical trade-offs in this area.

Sustainable and Biodegradable Options

Sustainability has moved from a secondary consideration to a primary driver in material selection decisions:

Bio-based polymers derived from renewable resources have expanded beyond PLA to include a diverse range of options with performance characteristics comparable to petroleum-based alternatives. These materials reduce carbon footprint while maintaining the functionality required for demanding applications.

According to StartUs Insights’ 2025 polymer industry analysis, "Innovations in the field of biopolymers include biodegradable, compostable, and renewable materials that effectively replace conventional plastics" (StartUs Insights, 2025). This transition is particularly evident in packaging applications, where regulatory pressures and consumer preferences have accelerated adoption.

Biodegradable additives and modifiers have been developed to enhance the performance of bio-based polymers, addressing historical limitations in areas such as moisture sensitivity, thermal stability, and impact resistance. These advancements have expanded the application range for sustainable materials, making them viable options for more demanding products.

Recycled content formulations have improved dramatically, with advanced sorting and purification technologies enabling the production of recycled materials with properties approaching virgin resins. Chemical recycling processes that break down polymers to their molecular building blocks have been particularly important in this evolution, allowing true circular use of materials that were previously difficult to recycle effectively.

Composite Materials and Reinforcements

Composite materials have seen significant innovation, with new reinforcement options and processing methods expanding their capabilities:

Natural fiber reinforcements, including bamboo, flax, and hemp, have emerged as sustainable alternatives to glass and carbon fibers in certain applications. These materials offer favorable strength-to-weight ratios while reducing environmental impact and often improving recyclability.

Nanomaterial reinforcements, including graphene, carbon nanotubes, and nanoclays, provide exceptional property enhancements at very low loading levels. These materials can dramatically improve mechanical strength, thermal conductivity, barrier properties, and electrical characteristics without significantly affecting processability or increasing weight.

Hybrid composites combining multiple reinforcement types have become more common, allowing engineers to optimize performance characteristics for specific applications. These sophisticated materials often incorporate both continuous and discontinuous reinforcements in carefully designed architectures that maximize performance while minimizing cost.

Functionalized reinforcements with surface treatments specifically designed for particular polymer matrices have improved interfacial bonding and overall composite performance. These treatments enhance load transfer between the matrix and reinforcement while improving dispersion and processing characteristics.

Material Consolidation Approaches

A notable trend in 2025 is the strategic consolidation of material selections to optimize supply chains and manufacturing operations:

According to a recent article in Plastics Technology, "After years of just-in-time ordering and application-specific customization, many medical manufacturers are recognizing the operational advantages of narrowing their resin selections. Fewer SKUs mean leaner inventories, simpler quality control and fewer regulatory hurdles when switching between production lines or contract manufacturers" (Plastics Technology, 2025).

This approach has expanded beyond medical applications to other industries, with manufacturers identifying opportunities to use fewer base materials across multiple products without compromising performance. The strategy often involves selecting versatile materials that can be modified through processing parameters or minor additive adjustments rather than requiring completely different formulations.

Material standardization initiatives have been implemented across global manufacturing operations, reducing complexity and enabling more efficient procurement, quality control, and regulatory compliance. These programs typically focus on identifying a core set of materials that can meet the requirements for a broad range of applications.

Cross-functional material selection teams have become standard practice, bringing together expertise from design, manufacturing, procurement, and sustainability departments to make holistic decisions that consider the full product lifecycle and business impact.

Regulatory Considerations in Material Selection

Regulatory compliance has become increasingly complex and influential in material selection decisions:

PFAS (per- and polyfluoroalkyl substances) regulations have driven significant reformulation efforts across multiple industries. As noted in Plastics Technology, "A prominent challenge facing medical OEMs and processors is the mounting regulatory pressure surrounding per- and polyfluoroalkyl substances (PFAS). In a growing number of jurisdictions, PFAS compounds are being banned or placed under intense scrutiny due to concerns over environmental persistence and human health impacts" (Plastics Technology, 2025).

This regulatory evolution has forced manufacturers to identify alternative additives and processing aids, particularly for applications requiring low friction, mold release, or dispersion properties. Siloxane-based alternatives have emerged as promising replacements in many cases, offering similar processing benefits without the environmental concerns associated with PFAS.

Global regulatory tracking systems have become essential tools for manufacturers operating in multiple markets, providing real-time updates on chemical regulations and material restrictions worldwide. These systems help companies anticipate compliance requirements and proactively adjust material selections before regulatory changes impact production.

Hazard assessment methodologies have evolved to evaluate not only the risks associated with materials themselves but also their breakdown products and environmental fate. This more comprehensive approach helps manufacturers avoid regrettable substitutions when reformulating to meet regulatory requirements.

Product Design Considerations

Product design for plastic parts has evolved significantly in 2025, with new methodologies and tools enabling more sophisticated approaches to design optimization. These considerations have become increasingly important as manufacturers seek to maximize performance while minimizing material usage, production costs, and environmental impact.

Design for Manufacturing (DFM) Best Practices

Design for Manufacturing has become more sophisticated and integrated into the product development process:

Simulation-driven DFM tools now provide real-time feedback during the design phase, highlighting potential manufacturing issues before they become costly problems. These tools analyze wall thickness, draft angles, undercuts, and other critical features, suggesting modifications that improve manufacturability without compromising product functionality.

Multi-process DFM considerations have gained importance as products increasingly combine components made through different manufacturing methods. Design guidelines now address the unique requirements of each process while ensuring that parts produced through different methods will integrate seamlessly in the final assembly.

Tolerance analysis has become more sophisticated, with statistical approaches replacing traditional worst-case scenarios. These methods provide a more realistic assessment of how dimensional variations will affect assembly and function, allowing designers to specify appropriate tolerances that ensure quality without unnecessarily increasing manufacturing costs.

Design standardization initiatives have been implemented across many organizations, establishing common features, dimensions, and approaches that improve manufacturing efficiency while reducing the need for custom tooling and setups. These standards typically include preferred wall thicknesses, corner radii, and other features optimized for specific manufacturing processes.

Lightweighting Strategies

Lightweighting continues to be a primary focus across multiple industries, driven by efficiency, sustainability, and performance requirements:

Topology optimization algorithms have become standard tools in the design process, automatically identifying opportunities to remove non-essential material while maintaining structural integrity. These algorithms analyze stress patterns and load paths, creating organic structures that maximize strength-to-weight ratios.

Lattice structures and controlled porosity have emerged as effective approaches to weight reduction in applications where solid sections were previously required. Advanced design software can now automatically generate optimized lattice patterns based on anticipated loading conditions, creating structures that would be impossible to design manually.

Material-specific design strategies have been developed to leverage the unique properties of different polymers and composites. These approaches consider not only mechanical characteristics but also processing behavior, ensuring that lightweight designs remain manufacturable at acceptable costs.

Multi-material design approaches strategically combine different materials to optimize both weight and performance. These designs typically place high-performance materials only where they’re needed most, using more economical or sustainable options elsewhere in the component.

Multi-Material and Overmolding Design

Multi-material components have become increasingly common, offering combinations of properties that cannot be achieved with single materials:

Interface design between different materials has advanced significantly, with sophisticated approaches to ensuring strong bonds and preventing delamination. These methods include mechanical interlocks, chemical bonding agents, and surface treatments optimized for specific material combinations.

Selective reinforcement through overmolding allows designers to enhance specific areas of a component without adding weight or complexity to the entire part. This approach is particularly valuable for high-stress regions, wear surfaces, and areas requiring specialized properties such as vibration damping or electrical insulation.

Material transition zones have been optimized to manage differences in thermal expansion, modulus, and other properties that can create stress concentrations in multi-material parts. Gradual transitions and intermediate materials help distribute stresses and prevent failures at material boundaries.

Aesthetic considerations in multi-material design have evolved beyond simple color contrasts to include sophisticated combinations of textures, transparencies, and surface finishes. These design elements enhance both visual appeal and functionality, with tactile features improving ergonomics and user experience.

Simulation and Digital Prototyping

Digital simulation tools have transformed the design process, reducing reliance on physical prototypes and accelerating development cycles:

Multi-physics simulation capabilities now allow designers to simultaneously evaluate structural, thermal, fluid, and electromagnetic behavior, providing a comprehensive understanding of how a part will perform in real-world conditions. These integrated analyses identify interaction effects that might be missed when considering each physics domain separately.

Injection molding simulation has advanced to include micro-scale effects such as fiber orientation, crystallinity development, and residual stress distribution. These detailed analyses provide more accurate predictions of part performance, particularly for engineering applications where these factors significantly influence mechanical properties.

Cloud-based simulation platforms have democratized access to sophisticated analysis capabilities, allowing even small manufacturers to leverage high-performance computing resources for complex simulations. These platforms typically offer pay-per-use pricing models that eliminate the need for expensive hardware and software investments.

Digital twins of both products and manufacturing processes enable continuous optimization throughout the product lifecycle. These virtual representations are updated with real-world data, creating feedback loops that improve both current and future designs.

Design for Sustainability and Circularity

Sustainability considerations have become integral to the design process, with new methodologies supporting circular economy principles:

Life cycle assessment (LCA) tools have been integrated directly into CAD systems, providing real-time feedback on the environmental impact of design decisions. These tools consider material selection, manufacturing processes, transportation, use phase, and end-of-life scenarios, helping designers identify and address environmental hotspots.

Design for disassembly has gained prominence as manufacturers take greater responsibility for end-of-life product management. Features such as snap-fits that can be released without damage, reversible bonding methods, and material identification markings facilitate recycling and component reuse.

Mono-material design strategies have been developed to improve recyclability without compromising product functionality. These approaches minimize the use of dissimilar materials and adhesives that complicate separation and recycling processes, often through innovative design solutions that achieve required properties with single-material constructions.

Renewable and recycled content utilization is now considered from the earliest design stages, with material selection and design features optimized for these often more variable feedstocks. Design approaches include more robust tolerance specifications, adaptive manufacturing parameters, and features that accommodate the unique characteristics of sustainable materials.

Quality Control and Assurance Methods

Quality control in plastic parts manufacturing has undergone significant transformation in 2025, with advanced technologies enabling more comprehensive, efficient, and proactive approaches to ensuring product quality. These developments have reduced defect rates while providing greater visibility into manufacturing processes.

Advanced Inspection Technologies

Inspection capabilities have evolved dramatically, with new technologies enabling more thorough and efficient quality verification:

Non-contact metrology systems using structured light and laser scanning technologies can now capture millions of data points in seconds, creating detailed 3D models of produced parts for comparison against design specifications. These systems identify dimensional deviations with micron-level precision, even on complex geometries and flexible materials that were challenging for traditional measurement methods.

Computed tomography (CT) scanning has become more accessible and efficient, allowing manufacturers to inspect internal features and detect defects that would be invisible to surface-based inspection methods. Advanced algorithms automatically analyze scan data to identify voids, inclusions, and other internal defects that could compromise part performance.

Hyperspectral imaging systems can now detect material variations, contamination, and inconsistencies that might not be visible to the human eye or conventional cameras. These systems are particularly valuable for verifying material consistency and detecting subtle surface defects in high-value components.

Automated visual inspection systems powered by artificial intelligence have dramatically improved defect detection capabilities. These systems learn from historical data to identify even subtle quality issues, adapting to new defect types and reducing false positives compared to rule-based inspection approaches.

In-Process Monitoring Systems

Real-time monitoring has transformed quality control from a post-production activity to an integral part of the manufacturing process:

In-mold sensors now provide continuous data on critical parameters such as pressure, temperature, and flow characteristics throughout the molding cycle. This information allows for immediate detection of process deviations that might lead to quality issues, enabling corrective action before defective parts are produced.

Ultrasonic and infrared monitoring systems track material behavior during processing, providing insights into crystallization, curing, and other material transformations that significantly impact final part properties. These technologies are particularly valuable for high-performance materials where processing conditions critically affect mechanical characteristics.

Vibration analysis systems detect subtle changes in machine operation that might indicate developing problems or process drift. Machine learning algorithms analyze these vibration patterns to identify specific issues such as tool wear, bearing problems, or valve malfunctions before they affect part quality.

Energy consumption monitoring provides another data stream for quality control, with unexpected changes in power usage often indicating process problems. These systems can detect issues such as increased friction, material inconsistencies, or developing mechanical problems that might not be immediately apparent through other monitoring methods.

Predictive Quality Analytics

Data analytics has revolutionized quality management, shifting focus from reactive inspection to proactive prevention:

Predictive quality models combine data from multiple sources—including process parameters, material characteristics, environmental conditions, and historical quality results—to forecast potential quality issues before they occur. These models continuously improve through machine learning, becoming more accurate as they process additional data.

Digital thread approaches maintain connections between design specifications, process parameters, material data, and quality results throughout the product lifecycle. This comprehensive traceability enables root cause analysis when issues arise and facilitates continuous improvement by identifying correlations between process variations and quality outcomes.

Statistical process control (SPC) has evolved from basic control charts to sophisticated multivariate analysis techniques that can detect complex patterns and interactions across dozens of process parameters simultaneously. These advanced methods identify subtle process shifts that might be missed by traditional SPC approaches.

Anomaly detection algorithms continuously monitor process data streams, automatically identifying unusual patterns that might indicate developing quality issues. These systems can detect problems that would be invisible to traditional threshold-based monitoring approaches, particularly when multiple parameters drift simultaneously within their individual acceptable ranges.

Traceability and Documentation

Documentation and traceability systems have become more comprehensive and integrated:

Blockchain-based traceability systems provide tamper-proof records of material sources, processing conditions, and quality test results throughout the supply chain. These systems are particularly valuable for medical, aerospace, and automotive applications where component history must be verifiable and secure.

Digital material passports accompany components throughout their lifecycle, containing comprehensive information about material composition, processing history, and performance characteristics. These passports facilitate recycling and reuse at end-of-life while providing valuable data for warranty management and continuous improvement.

Automated documentation systems capture and organize quality data without manual intervention, reducing administrative burden while improving record completeness and accuracy. These systems typically integrate with enterprise resource planning (ERP) and manufacturing execution systems (MES) to provide seamless information flow across the organization.

Real-time compliance verification tools continuously monitor quality data against regulatory and customer requirements, immediately flagging potential compliance issues. These tools automatically generate required documentation and certificates, streamlining audit processes and reducing compliance risks.

Regulatory Compliance Strategies

Regulatory compliance has become increasingly complex, requiring sophisticated management approaches:

Risk-based quality systems allocate quality control resources based on the potential impact of defects, focusing intensive inspection and monitoring on critical features while using more efficient approaches for less critical aspects. This strategy optimizes quality costs while ensuring appropriate scrutiny of features that affect safety, function, or regulatory compliance.

Harmonized compliance approaches address multiple regulatory frameworks simultaneously, identifying common requirements and implementing unified quality systems that satisfy all applicable standards. This approach is particularly valuable for manufacturers serving global markets with different regulatory requirements.

Automated regulatory intelligence systems continuously monitor changes in regulations and standards worldwide, alerting quality teams to upcoming requirements that might affect their products or processes. These systems help manufacturers proactively adapt their quality control approaches to maintain compliance in a changing regulatory landscape.

Supplier quality management has become more collaborative and data-driven, with shared quality metrics and real-time visibility into supplier processes. These approaches ensure that incoming materials and components meet quality requirements while building stronger partnerships throughout the supply chain.

Conclusion

The landscape of plastic parts manufacturing in 2025 reflects a remarkable convergence of technological innovation, environmental responsibility, and operational excellence. As we’ve explored throughout this article, manufacturers are navigating a complex terrain of opportunities and challenges, leveraging advanced technologies and methodologies to create products that meet increasingly demanding requirements.

Summary of Key Innovations

The most significant innovations shaping plastic parts manufacturing today span multiple dimensions of the production ecosystem:

Material science has advanced dramatically, with high-performance polymers, sustainable alternatives, and sophisticated composites expanding the possibilities for product design and functionality. The development of bio-based plastics and advanced recycling technologies has been particularly impactful, addressing longstanding environmental concerns while maintaining or enhancing performance characteristics.

Manufacturing processes have evolved through automation, digitalization, and precision engineering. From high-speed continuous 3D printing to multi-component injection molding with conformal cooling, these advancements have improved efficiency, quality, and design freedom across production methodologies.

Design approaches have become more sophisticated and integrated, with simulation-driven methodologies, topology optimization, and multi-material strategies enabling products that would have been impossible to create just a few years ago. The integration of sustainability considerations into the design process represents a fundamental shift in how products are conceived and developed.

Quality control has transformed from reactive inspection to proactive prevention through advanced monitoring technologies, predictive analytics, and comprehensive traceability systems. These approaches not only reduce defect rates but also provide valuable data for continuous improvement and regulatory compliance.

Impact on Efficiency, Sustainability, and Performance

The convergence of these innovations has delivered meaningful improvements across key performance indicators:

Efficiency gains have been substantial, with manufacturers reporting cycle time reductions of 20-40% through process optimization, automation, and advanced tooling designs. Material utilization has improved similarly, with sophisticated design approaches and process controls minimizing waste throughout production operations.

Sustainability improvements extend beyond material selection to encompass energy efficiency, water conservation, and waste reduction throughout the manufacturing process. The adoption of closed-loop systems and circular economy principles has reduced environmental impact while often delivering economic benefits through resource conservation and waste valorization.

Performance enhancements have been achieved through both material innovations and manufacturing precision. Products that are lighter, stronger, and more durable are now possible, with functional integration enabling new capabilities that address evolving market requirements across industries from medical devices to consumer electronics.

Future Outlook for Plastic Parts Manufacturing

Looking ahead, several trends are likely to shape the continued evolution of plastic parts manufacturing:

The integration of artificial intelligence and machine learning will accelerate across all aspects of manufacturing, from material development and design optimization to process control and quality assurance. These technologies will enable more autonomous operations and continuous improvement through data-driven decision making.

Sustainability will remain a central focus, with continued development of bio-based materials, recycling technologies, and design approaches that support circular economy principles. Regulatory pressures and market demands will further drive this transition toward more environmentally responsible manufacturing practices.

Customization and on-demand production will become more prevalent as flexible manufacturing systems and digital workflows reduce the economic barriers to producing specialized or personalized products. This shift will challenge traditional economies of scale while creating new opportunities for responsive, market-focused manufacturing.

Supply chain resilience will continue to influence manufacturing strategies, with increased emphasis on geographic diversification, material standardization, and digital supply networks that provide visibility and adaptability in a changing global landscape.

For engineering professionals and procurement specialists in the plastic parts manufacturing industry, staying informed about these developments and their implications will be essential for maintaining competitiveness and driving innovation. By embracing these advancements while maintaining focus on fundamental quality and efficiency principles, manufacturers can position themselves for success in an increasingly dynamic and demanding marketplace.

The future of plastic parts manufacturing will belong to those who can effectively balance technological sophistication, environmental responsibility, and operational excellence—creating products that meet the complex requirements of tomorrow’s markets while addressing the sustainability challenges that have become imperative for our shared future.