Investment Casting Explained: Achieving Miniature & Intricate Designs

Investment casting—also known as lost wax casting—is a manufacturing method renowned for its ability to produce intricate, miniature, and high-precision components. It allows for the production of parts with tight tolerances, fine surface finishes, and complex geometries that are often difficult or impossible to achieve through other casting or machining techniques. This guide provides a comprehensive overview of the investment casting process, suitable materials, quality controls, and industry applications.

What Is Investment Casting?

Investment casting is a precision casting process used to create complex and highly detailed components by forming a ceramic mold around a wax model. Once the mold is formed, the wax is melted away and replaced with molten metal, resulting in a highly accurate final product.

🔍 Key Advantages:

- Produces near-net-shape parts

- Exceptional surface finish (Ra 1.6–3.2 µm)

- Tight dimensional tolerances (±0.05 mm)

- Can replicate fine lettering or thin walls

- Requires minimal post-processing

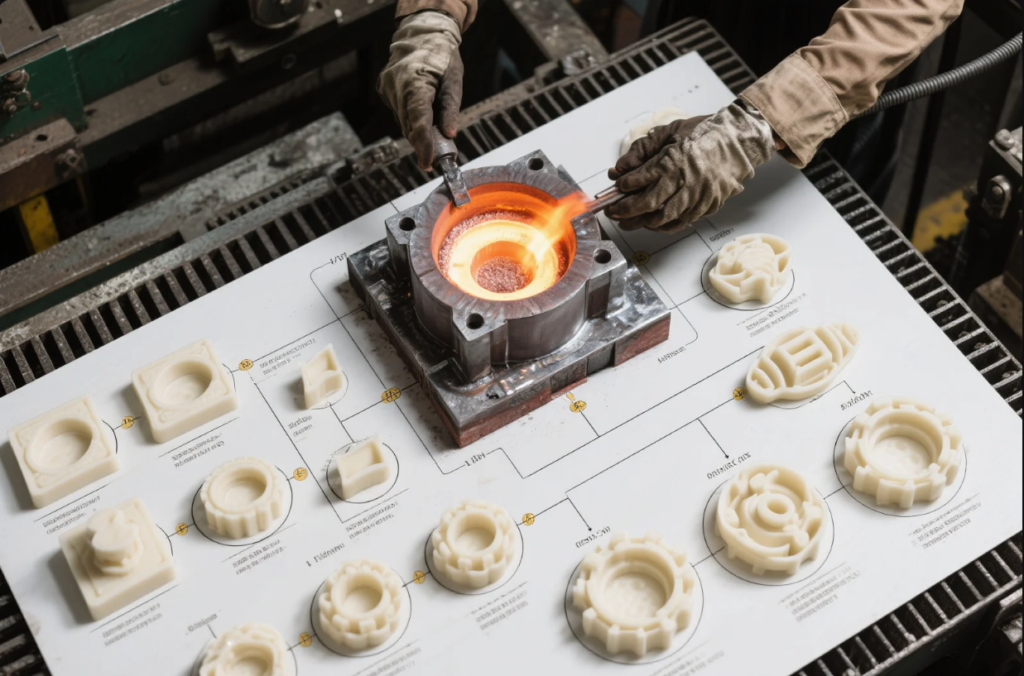

Step-by-Step Investment Casting Process

1. Wax Pattern Creation

A wax replica of the desired part is created, often using injection molds for repeatability.

2. Pattern Assembly

Multiple wax patterns are assembled onto a sprue to form a “tree” for mass casting.

3. Ceramic Shell Building

The wax assembly is dipped into a slurry and coated with fine ceramic particles. This process is repeated several times to form a thick, heat-resistant shell.

4. Dewaxing

The ceramic-coated assembly is placed in an autoclave or furnace to melt and remove the wax.

5. Shell Firing

The empty ceramic mold is fired to harden it and remove residual wax.

6. Metal Pouring

Molten metal is poured into the hot mold, filling the cavity left by the wax pattern.

7. Cooling and Shell Removal

After cooling, the ceramic shell is broken off to reveal the raw casting.

8. Finishing

The part is cut from the sprue, then cleaned, ground, and polished as needed.

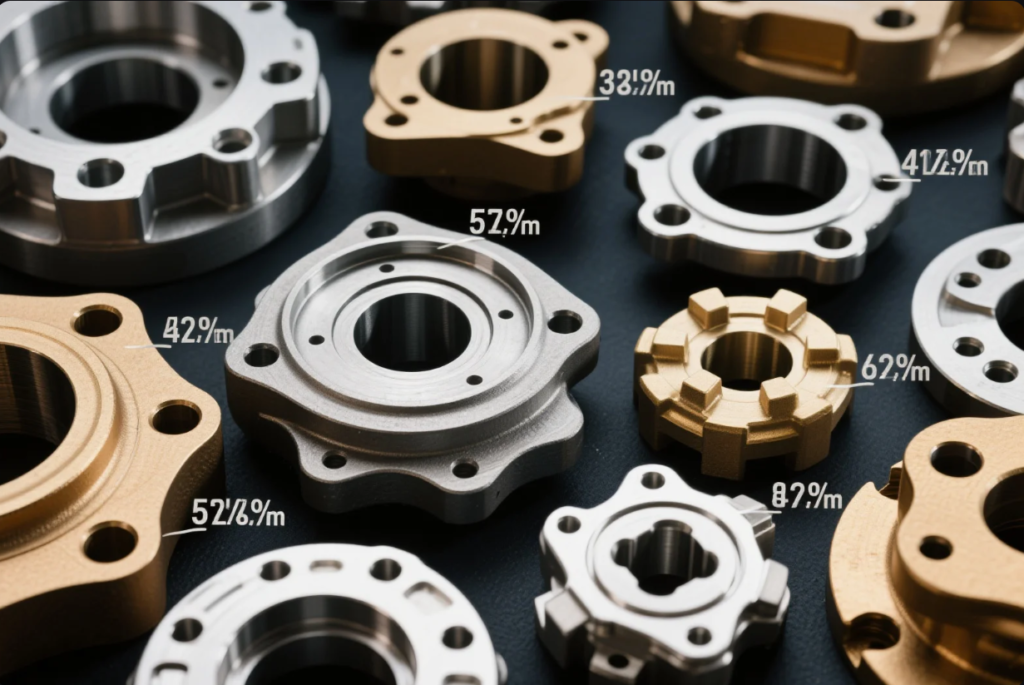

Materials Used in Investment Casting

Investment casting supports a wide range of metals and alloys, making it ideal for diverse industries.

🟦 Steel Alloys

- Carbon steel, stainless steel, tool steel

- Used for structural parts, valves, gears, and turbine blades

🟩 Copper-Based Alloys

- Brass, bronze

- Ideal for plumbing fixtures, decorative parts, and corrosion-resistant applications

🟨 Nickel-Based Alloys

- Inconel, Monel, Hastelloy

- Common in aerospace and chemical processing industries

🟧 Magnesium Alloys

- Lightweight and strong, used in aerospace and automotive sectors

🔗 Matmatch: Overview of Cast Metal Alloys

Surface Finishes & Quality Control

✨ Surface Finishing

Investment casting naturally results in smooth surface finishes:

- As-cast surface roughness: Ra 1.6–3.2 µm

- Machined finish (optional): up to Ra 0.8 µm

- Polishing, electropolishing, or coating can be applied if required

🛠️ Quality Inspection Methods

- Dimensional measurement with calipers, micrometers, or CMMs

- X-ray or CT scan for internal voids and defects

- Spectrometer analysis for alloy composition

- Surface crack detection using dye penetrant or magnetic particle inspection

🔗 AZoM: Surface Quality in Precision Casting

Applications Across Industries

🏥 Medical Devices

- Surgical scissors, forceps, orthopedic implants

- Stainless steel or cobalt-chromium alloys

💍 Jewelry

- Rings, pendants, detailed settings

- Enables creation of ultra-fine decorative elements in precious metals

🎯 Precision Instruments

- Clocks, microscopes, scientific equipment

- Critical for parts requiring exact tolerances and smooth operation

✈️ Aerospace & Defense

- Fuel nozzles, turbine blades, brackets

- Lightweight and high-precision components for extreme environments

⚙️ Industrial Machinery

- Impellers, pump parts, valve bodies

🔗 Reliance Foundry: Applications of Investment Casting

FAQs

Q1: What is the smallest feature investment casting can reproduce?

A: Features as small as 0.5 mm and wall thicknesses down to 0.3 mm are possible.

Q2: What are the typical batch sizes?

A: From a few prototypes to thousands per month. It’s flexible for both.

Q3: Can I use my own alloy or custom specifications?

A: Yes. Custom compositions and properties can be cast to order.

Q4: How accurate is investment casting?

A: Tolerances of ±0.05 mm are standard. Post-machining can achieve tighter specs.

Q5: Is investment casting suitable for high-strength parts?

A: Yes. Alloy steels and nickel-based alloys make it ideal for load-bearing parts.

Contact Us

Ready to bring your intricate designs to life?

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

🏭 Shandong Prime International Trade Co., Ltd.

Exporting high-precision castings globally since 1993. ISO-certified. Fast delivery. Custom support.

© 2025 PrimeCustomParts.com — Miniature Precision Delivered Globally