Is a Wood CNC Worth It?

Leading paragraph: Facing inconsistent wood cuts? Deciding whether CNC machining solves your production challenges requires careful cost-benefit analysis.

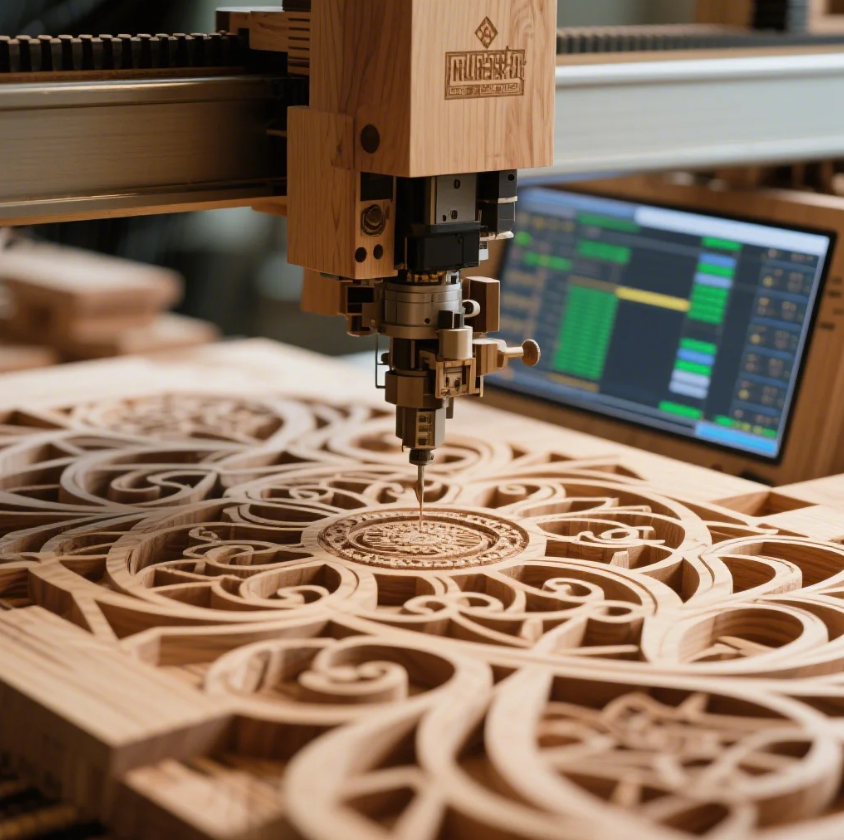

Snippet paragraph: Wood CNCs provide exceptional precision and repeatability for professional woodworking, with industrial models offering 5-10x faster production than manual methods when properly utilized.

Transition paragraph: Let’s examine the real numbers behind CNC woodworking investments.

What Are 3 Disadvantages of a CNC Machine?

Leading paragraph: Before choosing CNC technology, understand these critical limitations that impact operations.

Snippet paragraph: Primary CNC disadvantages include high upfront costs (5-axis models start at $40,000), steep learning curves requiring 80-120 training hours, and limited flexibility for last-minute design changes.

Dive-Deeper paragraph:

Addressing Common CNC Challenges

Challenge 1: High Capital Investment

- Entry-Level Solutions: Desktop CNCs from $3,000 (limited to 12"x12" work area)

- Mid-Range Option: 4’x8′ industrial CNCs (~$60,000 with vacuum hold-down)

- Prime Alternative: Our $0 minimum order policy eliminates equipment costs

Challenge 2: Maintenance Requirements

| Component | Maintenance Frequency | Estimated Annual Cost |

|---|---|---|

| Spindle Bearings | 2,000 hours | $1,200 |

| Linear Guides | Quarterly | $800 |

| Cutting Tools | 50-100 hours | $3,500 |

Challenge 3: Dust Collection Needs

Our facility solves this with:

- 5HP cyclone systems (captures 99.97% particulates)

- Automated tool cleaning between operations

- ISO Class 7 cleanroom finishing areas

How Much Does a Wood CNC Cost?

Leading paragraph: CNC pricing ranges from hobbyist toys to industrial workhorses – know which tier matches your output needs.

Snippet paragraph: Professional wood CNCs range from $25,000 for basic 3-axis to $250,000+ for 5-axis automation cells, with Prime offering contract machining at $18-$65/hour depending on complexity.

Dive-Deeper paragraph:

Breaking Down CNC Ownership Costs

Initial Purchase Factors

- Work Area: Add $15,000 per extra foot of X-axis beyond 4′

- Spindle Power: 5HP vs 15HP affects cut speed by 40-60%

- Control Software: Advanced packages add $8,000-$12,000

Hidden Operational Expenses

| Cost Category | Annual Estimate | Notes |

|---|---|---|

| Software Updates | $2,500 | CAM license renewals |

| Tooling | $8,000 | End mills, drills, bits |

| Operator Training | $6,000 | 80 hours @ $75/hour |

| Downtime Losses | $18,000 | 5% production loss assumption |

Better Alternative: Prime’s turnkey service includes all these costs in our $45/hour machining rate.

Is It Cheaper to Build or Buy CNC?

Leading paragraph: DIY CNC projects tempt cost savings, but often lead to frustrated engineers and botched jobs.

Snippet paragraph: Building a CNC typically costs 60-80% of commercial models but requires 300-500 assembly hours and delivers 30-50% lower precision – our clients save $11,000 average by outsourcing instead.

Dive-Deeper paragraph:

The True Economics of DIY CNC

Component Cost Comparison (4’x8′ Machine)

| Part | DIY Cost | Commercial Cost | Quality Difference |

|---|---|---|---|

| Linear Rails | $1,200 | $3,800 | 0.01mm vs 0.001mm precision |

| Spindle | $900 | $6,500 | 8,000h vs 30,000h lifespan |

| Control System | $1,500 | $12,000 | Basic vs adaptive toolpaths |

Time Investment Analysis

- Sourcing Parts: 40-60 hours

- Mechanical Assembly: 120 hours

- Electrical Wiring: 80 hours

- Software Config: 100 hours

- Calibration: 60 hours

Our clients value having these 400+ hours for core business instead.

Are CNC Machines Worth It?

Leading paragraph: The ROI question every woodworking business faces – here’s how to calculate your break-even point.

Snippet paragraph: CNC becomes profitable at ~1,500 annual parts by reducing labor by 70% and material waste by 25% – Prime helps smaller batches achieve similar savings through shared capacity.

Dive-Deeper paragraph:

Calculating Your CNC Payback Period

Production Variables

| Factor | Manual | CNC | Improvement |

|---|---|---|---|

| Cabinet Doors/hour | 4 | 28 | 600% |

| Material Yield | 82% | 94% | 12% |

| Error Rate | 9% | 0.5% | 94% |

Financial Analysis (First Year)

| Scenario | DIY CNC | Prime Contract | Manual Only |

|---|---|---|---|

| Initial Outlay | $41,000 | $0 | $0 |

| Annual Output | 800 units | 1,200 units | 400 units |

| Gross Profit | $64,000 | $96,000 | $32,000 |

Key Insight: Outsourcing achieves better returns than owning until exceeding 2,000 annual parts.

Conclusion

Wood CNCs transform production quality – but only make financial sense above specific volume thresholds or through contract manufacturing.

Stop Wasting Time on Trial-and-Error: Prime’s ISO-certified wood CNC services deliver:

- 15-day standard lead times

- +/-0.1mm precision guarantees

- Custom finishing/packaging

- No minimum order quantities

[Contact our engineering team] today for a free project assessment and sample quote.

SEO Keywords:

- "precision wood CNC cutting services"

- "CNC router cost vs outsourcing"

- "industrial woodworking CNC solutions"

- "ISO-certified wood machining"

- "low volume CNC wood parts"