Is it OK to Use Steel Screws in Aluminum?

Steel screws seem strong—but mixing metals can cause problems fast.

Mixing steel screws with aluminum can lead to galvanic corrosion. Choosing the wrong fasteners may weaken your structure over time. Using ISO-certified fasteners from a trusted supplier helps prevent this issue.

If you’re facing screw corrosion or unexpected failures, you’re not alone. Many buyers don’t realize the impact of metal compatibility. Read on to find out how to choose the right screws for aluminum and avoid costly mistakes.

Can I Use Steel Screws on Aluminum?

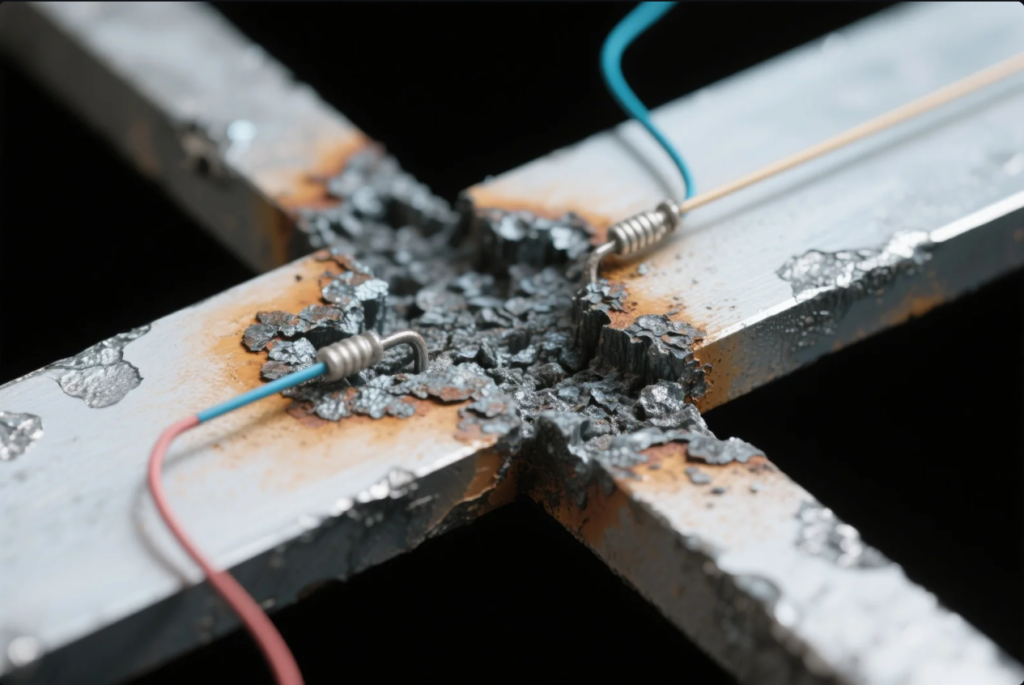

Using steel screws on aluminum may seem harmless. But this combination often leads to galvanic corrosion.

Steel and aluminum have different electrochemical properties. When exposed to moisture, they form a galvanic cell, causing aluminum to corrode faster.

This corrosion weakens joints, creates maintenance issues, and may even cause structural failures.

Why Galvanic Corrosion Happens

Galvanic corrosion occurs when two dissimilar metals contact in the presence of an electrolyte (like water or humidity). Aluminum, being more anodic, corrodes to protect the steel screw.

| Metal | Position in Galvanic Series | Tendency to Corrode |

|---|---|---|

| Aluminum | Anodic (Active) | High |

| Steel | Cathodic (Noble) | Low |

How to Prevent It

- Use barrier coatings (e.g., zinc plating or anti-seize compound)

- Add plastic washers or sleeves between the screw and aluminum

- Select corrosion-resistant screws like stainless steel or aluminum

At Prime, we supply ISO-certified fasteners with optional coatings and precise engineering. With over 20 years of experience, we help global buyers avoid galvanic risks in fastener assemblies.

What Is the Best Screw to Hold in Aluminum?

Many buyers ask which screws give the strongest hold in aluminum. The answer depends on application, load, and environment.

The best screws for aluminum are usually stainless steel, aluminum, or coated carbon steel screws. Their compatibility reduces corrosion and increases long-term performance.

Thread design also matters. For soft aluminum, coarse threads provide better grip. For precise assemblies, machine screws offer consistent holding strength.

Recommended Screw Materials for Aluminum

| Screw Material | Corrosion Resistance | Strength | Use Case |

|---|---|---|---|

| Stainless Steel 304 | Excellent | High | Outdoor and marine environments |

| Stainless Steel 316 | Superior | Very High | High-humidity and chemical exposure |

| Zinc-Plated Steel | Moderate | Medium | Dry indoor use only |

| Aluminum Screws | Good | Medium | Lightweight assemblies, low stress |

Prime supports customized fastener sourcing. Whether you need coarse-threaded aluminum screws or precision CNC fasteners, we offer flexible customization and short lead times.

What Screws Are Compatible with Aluminum?

Compatibility goes beyond material choice. Buyers also need to consider thread type, coatings, and tolerance.

Compatible screws for aluminum include stainless steel screws with insulating washers, aluminum screws, and properly coated carbon steel fasteners.

Using ISO-certified fasteners reduces risk. Always match thread sizes and avoid mismatched galvanic pairings.

Choosing the Right Screw for Aluminum

- For outdoor use: stainless steel (304 or 316)

- For lightweight parts: anodized aluminum screws

- For coated surfaces: use plastic or nylon washers

- For high-vibration applications: consider thread-locking screws

Our factory at Prime produces fasteners with precision tolerance and customized coatings. We help engineers worldwide choose the right screws for each aluminum application.

Common Long-Tail Search Terms

- “compatible screws for aluminum parts”

- “customized aluminum fasteners supplier”

- “ISO-certified screw manufacturer China”

- “corrosion-proof screws for aluminum”

Will Aluminum and Steel Corrode Together?

Yes, aluminum and steel can corrode together if not separated. This is one of the most common buyer mistakes.

When aluminum and steel touch and moisture is present, galvanic corrosion starts. The aluminum will degrade, even if the steel appears fine.

This not only weakens structures but leads to expensive maintenance and safety risks.

How to Safely Combine Steel and Aluminum

| Prevention Method | Description |

|---|---|

| Insulation | Use nylon or plastic washers |

| Protective Coating | Apply paint or galvanic coatings to fasteners |

| Use of Sealants | Silicone or other sealants reduce electrolyte access |

| Material Selection | Prefer stainless steel or coated screws |

At Prime, we take this problem seriously. Our engineers advise customers on safe fastener pairings, and our products meet strict ISO standards. We help prevent galvanic failures before they happen.

FAQs

Q1: Can I use stainless steel screws with aluminum?

A1: Yes, but it’s essential to use insulating materials like plastic washers to prevent galvanic corrosion.

Q2: What is galvanic corrosion?

A2: It’s an electrochemical process where one metal corrodes faster when in contact with a different metal in the presence of an electrolyte.

Q3: How can I prevent corrosion when using dissimilar metals?

A3: Use barrier coatings, insulating materials, and select compatible metals to minimize the risk.

Q4: Are aluminum screws a good option?

A4: Aluminum screws are suitable for lightweight applications but may not offer the strength required for heavy-duty uses.

Q5: Does Prime offer customized fastener solutions?

A5: Yes, Prime provides customized fasteners tailored to your specific requirements, ensuring compatibility and performance.

Conclusion

Mixing metals can damage structures. Use compatible fasteners to protect aluminum parts.

Ready to protect your aluminum structures from corrosion? Contact Prime today for free technical consultation, accurate quotes, and custom fastener solutions. We guarantee fast delivery, reliable quality, and responsive support. Get a competitive edge by partnering with an ISO-certified fastener manufacturer trusted by global buyers.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com