Is laser cutting cheaper than CNC?

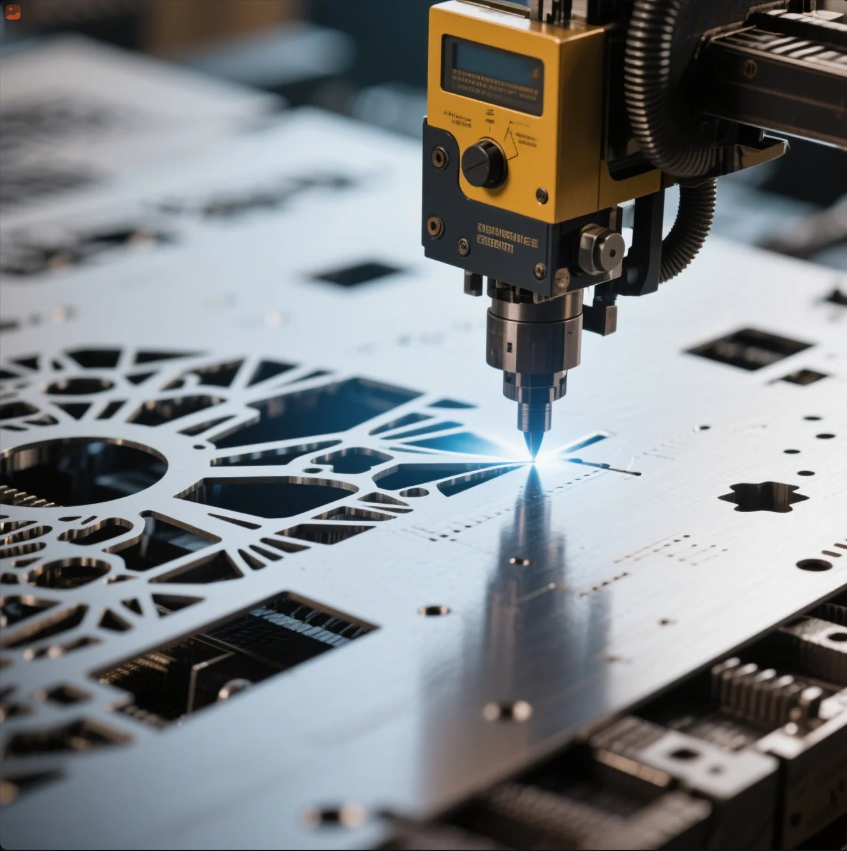

Both CNC machining and laser cutting shape metal—but their costs and use cases differ.

Laser cutting is often cheaper than CNC for thin, flat parts. CNC is better for complex shapes, 3D contours, and tight tolerances.

In this article, I’ll compare the two methods based on cost, performance, and application—so you can choose the most efficient process for your parts. At Prime, we offer both.

Is laser cutting better than CNC?

Both have strengths. Laser cutting is fast. CNC is precise.

Laser cutting is better for speed and volume. CNC is better for accuracy and complexity.

Which one should you choose?

| Feature | Laser Cutting | CNC Machining |

|---|---|---|

| Best for | Flat sheets, cutouts | Complex shapes, pockets, 3D features |

| Cutting speed | Very fast | Slower per part |

| Material waste | Minimal | Moderate |

| Setup time | Short | Longer |

| Tolerance | ±0.1 mm (standard) | ±0.01 mm (high precision) |

At Prime, we often combine both—using laser cutting for profiles, then CNC零件精准加工 for holes, threads, or finishing details.

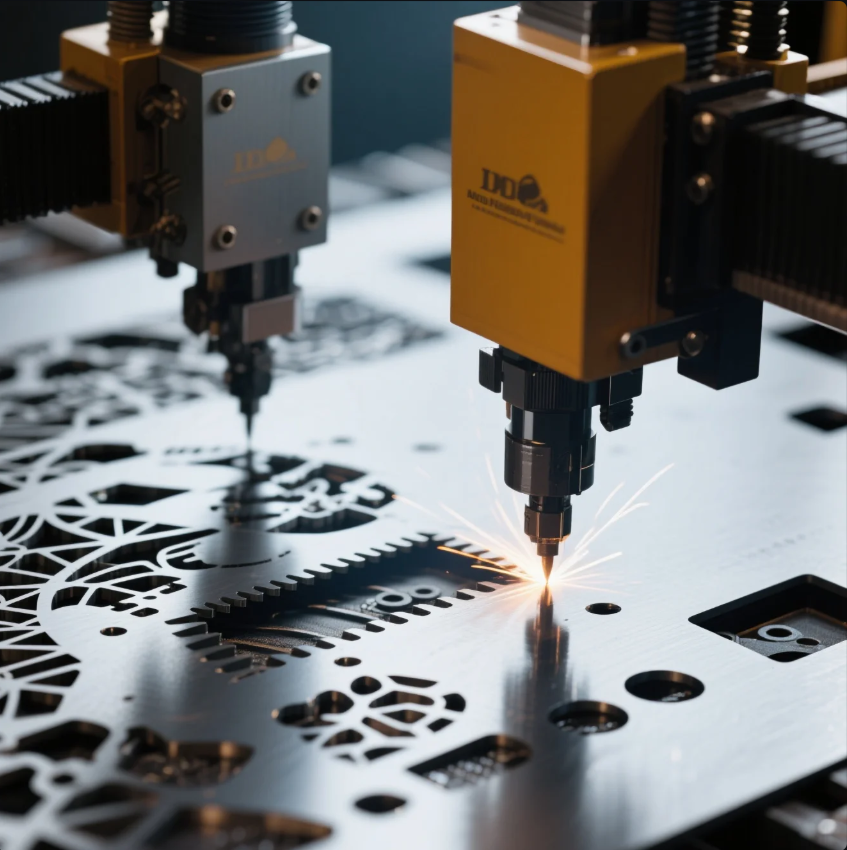

What is the main disadvantage of laser cutting?

Laser cutting has limits—especially with thick or highly reflective materials.

The main disadvantages of laser cutting are heat distortion, limited depth, and poor performance on thick or shiny metal.

When laser cutting isn’t the best fit

Laser cutting may not work well if:

- You need deep cavities or pockets

- The material is too thick (over 25mm steel)

- You want mirror-finish metals (e.g. copper or brass)

| Limitation | Reason | Alternative |

|---|---|---|

| Heat-affected zones | May cause warping on thin parts | CNC or waterjet |

| Low reflectivity cutting | Trouble with aluminum, brass, copper | CNC milling or fiber laser |

| Thickness limit | Reduced accuracy at high thickness | Plasma or saw cutting |

We help clients choose hybrid processes that reduce these risks while keeping costs low.

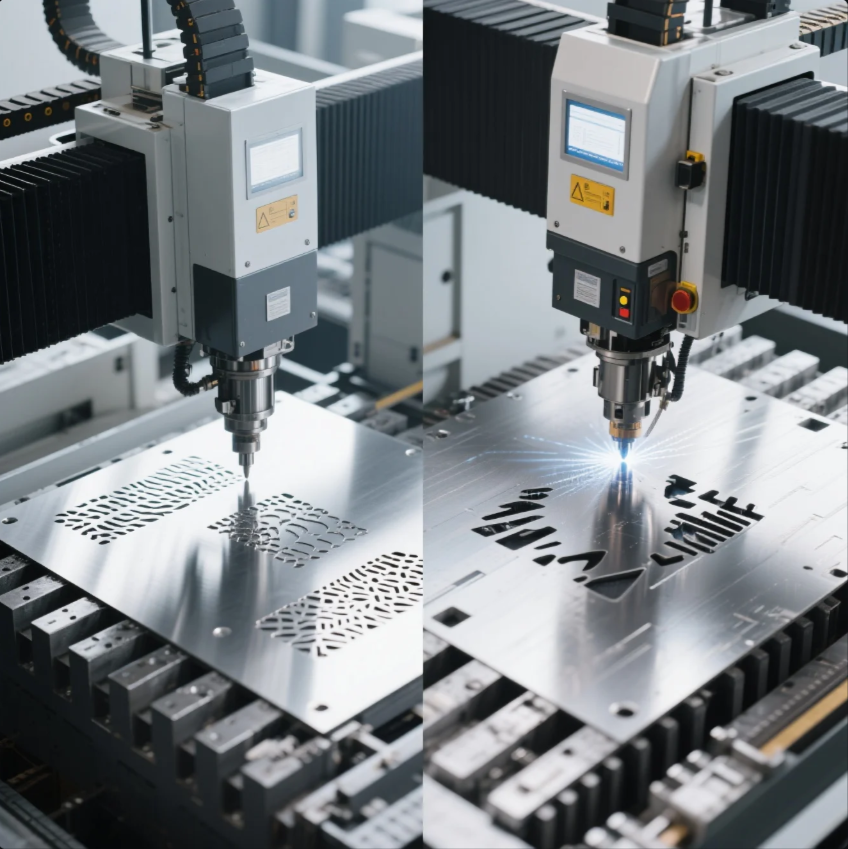

Is it expensive to run a laser cutter?

Laser cutters are efficient but require skilled setup, gas, and maintenance.

Running a laser cutter is moderately expensive. Electricity, assist gas, and maintenance add to cost—but it’s still cheaper than CNC for many jobs.

What contributes to operating cost?

| Cost Factor | Description |

|---|---|

| Power Consumption | High for thick metal, moderate otherwise |

| Gas Usage | Nitrogen, oxygen, or air needed |

| Lens and Nozzle Wear | Regular replacements needed |

| Maintenance Labor | Skilled technician required |

At Prime, we use automated nesting software and bulk processing to reduce laser operating costs per part—especially for mining and construction sheet metal components.

How much does laser cutting cost?

Laser cutting costs vary based on material, thickness, design, and order volume.

Typical laser cutting costs range from \$0.10 to \$1.00 per inch, depending on job complexity.

Key factors that affect price

| Factor | Impact on Cost |

|---|---|

| Material type | Stainless steel and aluminum cost more |

| Thickness | Thicker material needs slower cutting |

| Design complexity | More paths = longer cut time |

| Quantity | Higher volume = lower cost per unit |

We help clients reduce cost by:

- Suggesting material substitutions

- Using common plate sizes

- Combining laser and stamping for high-volume parts

With our ISO-certified production and in-house laser + CNC capacity, we deliver both cost-effective and high-precision parts on a tight schedule.

Conclusion

Laser cutting is faster and often cheaper than CNC—especially for flat parts. CNC wins for complex 3D work.

Need help choosing between laser cutting and CNC machining? Contact Shandong Prime International Trade Co., Ltd. today. We offer free process consultation, custom quoting, and fast global delivery. Let’s optimize your part design—for cost, quality, and lead time.