Is metal fabrication a good career?

Wondering if metal fabrication offers long-term career value?

Metal fabrication is a skilled trade with strong job stability, competitive pay, and opportunities for growth in manufacturing, construction, and engineering industries.

Many young workers or career changers ask if it’s worth the effort. I’ll break it down so you can decide if this path fits your goals—or if you’re hiring, understand what motivates fabricators.

Is metal fabrication a good career path?

Choosing a hands-on career can feel risky in a tech-heavy world.

Metal fabrication offers strong job demand, reliable income, and a clear path for skill development. It suits people who enjoy building things and solving mechanical challenges.

At Prime, we’ve trained over 100 workers into skilled roles. Many of them now lead projects for custom stamping parts and ISO-certified CNC fabrication.

Reasons Why Fabrication Is a Solid Career

| Advantage | Explanation |

|---|---|

| Skill-based growth | More experience = higher pay and job security |

| Global demand | Needed in nearly every industrial sector |

| Tangible output | See your work in finished machines and tools |

| Low entry barrier | Many roles start with vocational or on-job training |

It’s not just a job—it’s a trade that builds lifelong skills and solid income.

What is the highest paying job in fabrication?

Some roles in fabrication pay much more than others.

Specialized roles like welding inspectors, CNC programmers, and metal fabrication supervisors command the highest salaries.

At Prime, we’ve seen CNC programmers earn more than twice the entry-level wage due to their technical value in high-tolerance precision machining.

Top-Paying Fabrication Roles

| Job Title | Avg. Salary (USD) |

|---|---|

| Welding Inspector | \$60,000 – \$90,000 |

| CNC Programmer | \$55,000 – \$80,000 |

| Sheet Metal Foreman | \$50,000 – \$75,000 |

| Fabrication Engineer | \$65,000 – \$100,000 |

Those with CAD, CAM, and metallurgy knowledge are especially in demand. Prime supports upskilling to keep our team competitive.

Is metal fabrication lucrative?

You might wonder if it pays enough long term.

Metal fabrication can be lucrative—especially in specialized roles or for those running their own workshops.

At Prime, our lead fabricators have built long-term careers with increasing earnings. Some even started their own businesses after gaining experience in precision welding, assembly, and sheet metal production.

What Makes Fabrication Profitable

| Factor | How It Boosts Earnings |

|---|---|

| Specialization | CNC, TIG welding, robotic programming |

| Volume efficiency | Learning lean workflows cuts waste |

| Certifications | AWS, ISO, or national trade licenses |

| Industry focus | Aerospace, defense, and medical pay more |

Fabricators who build niche expertise gain higher pay, more job options, and even ownership paths.

Is it hard to be a metal fabricator?

Yes, the job has challenges—but they’re part of what makes it valuable.

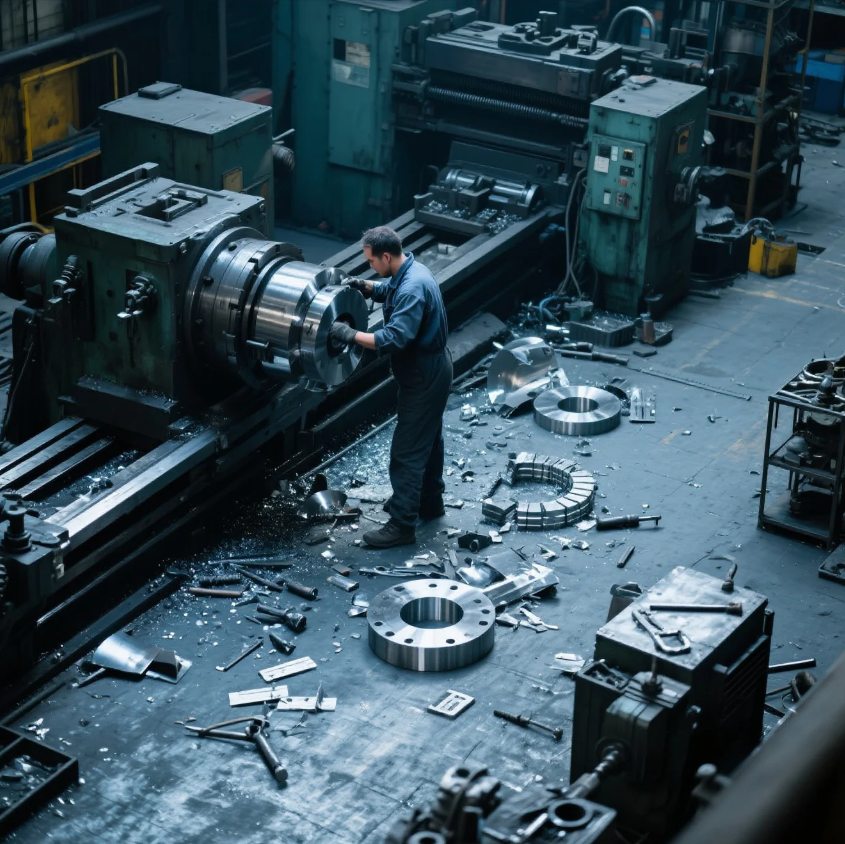

Being a metal fabricator requires manual skill, attention to detail, and safety awareness. But with proper training and good tools, it becomes a well-controlled process.

At Prime, we automate wherever possible. That keeps the workload manageable and helps our team focus on quality output for custom CNC and casting parts.

What Fabricators Deal With Daily

| Challenge | Why It Matters |

|---|---|

| Standing long hours | Needs endurance and comfort setup |

| Sharp tools & machines | Safety practices are critical |

| High precision work | Mistakes cost material and time |

| Reading blueprints | Accuracy starts with clear interpretation |

It’s not easy work, but it’s meaningful—and fabricators are respected in every industry.

Conclusion

Metal fabrication is a strong, skilled career with good pay and long-term value.

Hiring or sourcing from skilled fabricators? Prime brings 20+ years of expertise in sheet metal, welding, CNC, and casting. Contact us today to get ISO-certified quality, competitive pricing, and expert production support—all from one partner.