Is sheet metal fabrication hard?

Worried that sheet metal fabrication is too complex to manage?

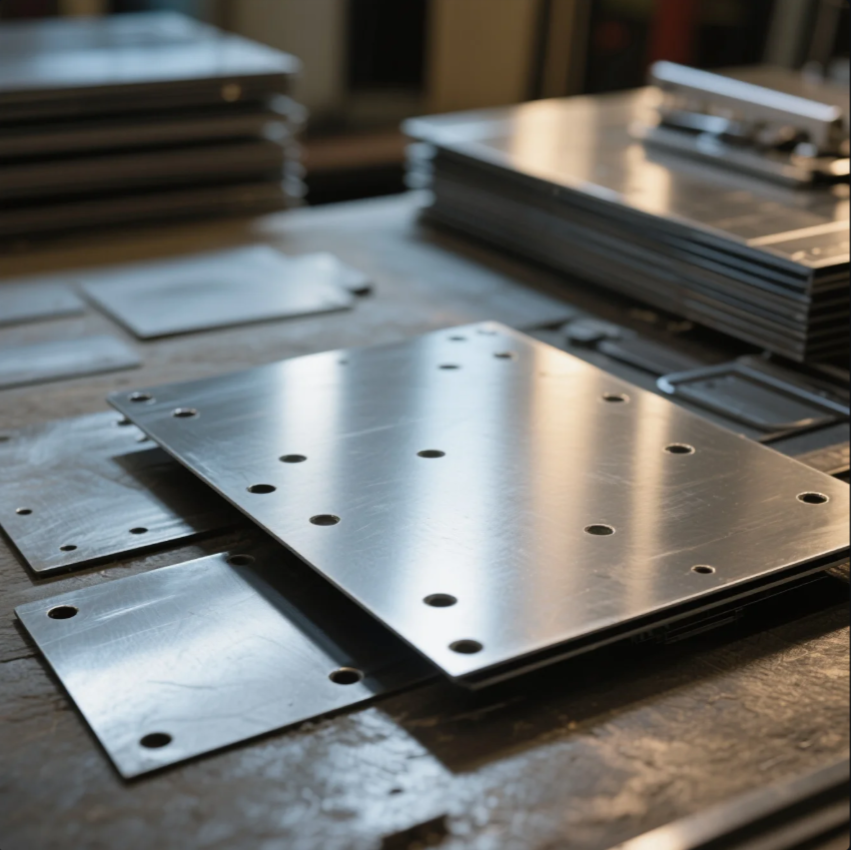

Sheet metal fabrication requires technical skill, planning, and precision—but the right tools and experience make it efficient and repeatable.

Many buyers assume fabrication is unpredictable or error-prone. In reality, experienced suppliers like Prime use proven workflows to deliver consistent, high-quality results.

Is sheet metal fabrication difficult?

It seems tough when every part needs precision and every angle must match.

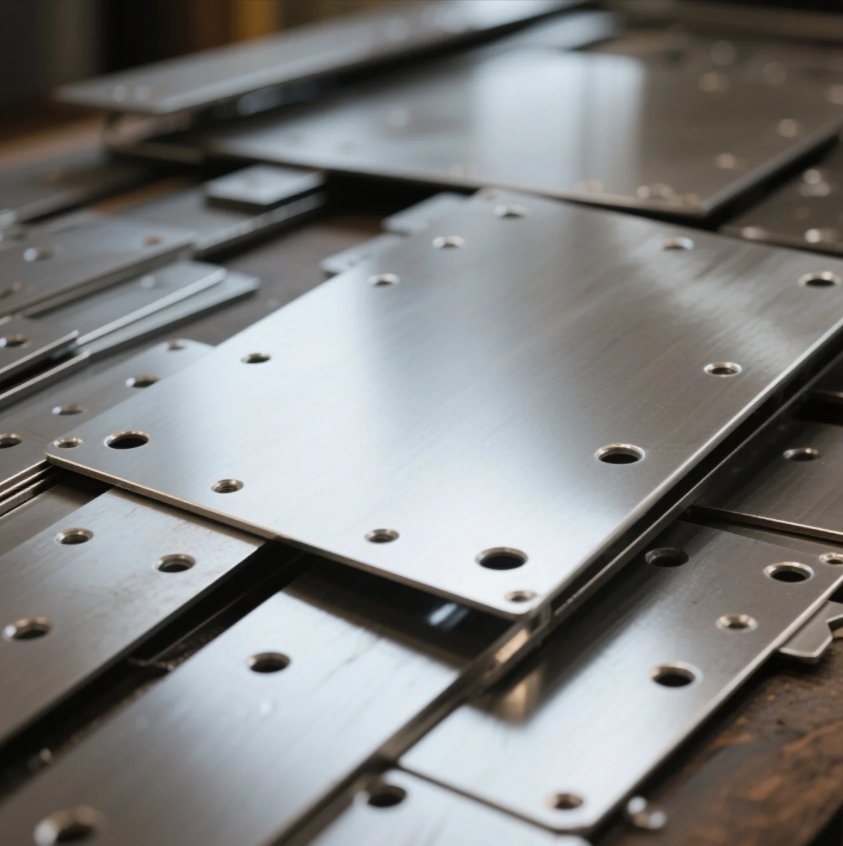

Sheet metal fabrication is challenging at first, but with skilled labor, proper tooling, and good planning, it becomes a highly efficient process.

At Prime, we use automated production lines and strict quality systems. Our team handles everything from simple brackets to complex ISO-certified assemblies, making fabrication easier for our clients.

Why Sheet Metal Work Seems Difficult

| Challenge | Prime’s Solution |

|---|---|

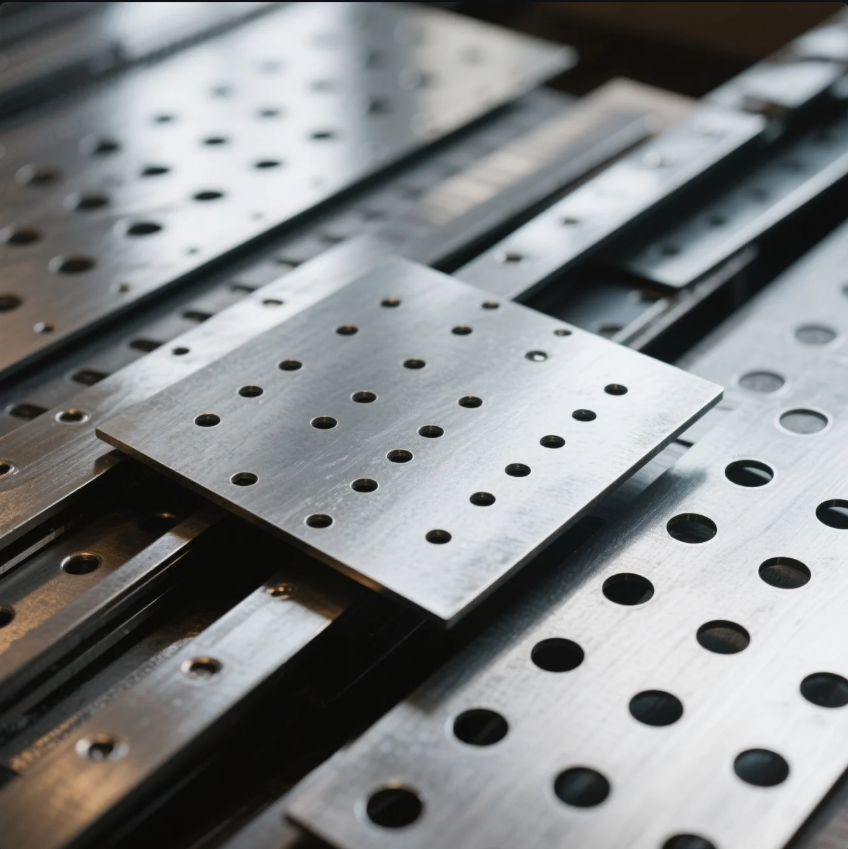

| Tight tolerances required | CNC calibration and in-process inspections |

| Material springback | Press brake compensation software |

| Complex designs | Design-for-manufacturing (DFM) reviews |

| High volume consistency | Automated lines + QA checkpoints |

Clients trust us because we make difficult parts simple to order—and easier to scale.

What kind of math do sheet metal workers use?

Many people don’t realize how math-heavy metal work can be.

Sheet metal workers use basic arithmetic, geometry, and trigonometry. They apply math to measure bends, calculate angles, and determine material use.

At Prime, our production planners use CAD tools to automate calculations. This reduces manual error and speeds up quoting and setup.

Common Math in Sheet Metal Work

| Math Type | Application Example |

|---|---|

| Arithmetic | Material quantity, cost estimation |

| Geometry | Bend allowances, layout planning |

| Trigonometry | Angles for complex bends or rolled parts |

| Unit Conversion | mm/inch, kg/lb, thickness gauge changes |

Buyers don’t need to know all this math. That’s our job. You just send us the drawings—we do the rest.

Is it hard to be a metal fabricator?

Metal fabrication takes more than physical effort—it needs patience and precision.

Being a metal fabricator can be physically demanding and detail-oriented. But with training and tools, it becomes a rewarding and stable career.

At Prime, many of our technicians have over 10 years of experience. We invest in safety, automation, and ongoing skill development. This creates a team that knows how to handle any project—from precision CNC parts to bulk stamping jobs.

Skills Needed to Be a Fabricator

| Skill | Why It Matters |

|---|---|

| Attention to Detail | Ensures accuracy in cutting and bending |

| Tool Proficiency | Speeds up setup and reduces errors |

| Blueprint Reading | Allows correct interpretation of specs |

| Safety Awareness | Prevents injury and maintains uptime |

Skilled fabricators are key to our reliability. Their precision becomes your product quality.

Where do sheet metal workers make the most money?

Wages vary—but some regions pay much more for skilled metal workers.

Sheet metal workers earn the most in areas with high demand and strict building codes. The U.S., Canada, Germany, and Australia offer some of the top salaries.

In the U.S., unionized roles in construction or HVAC can earn over \$70,000 annually. In manufacturing-focused regions like Shenzhen or Ningbo, China, wages are lower but still competitive due to living cost differences.

Global Sheet Metal Salary Ranges

| Country | Avg. Annual Salary (USD) |

|---|---|

| USA | \$50,000 – \$75,000 |

| Germany | \$40,000 – \$65,000 |

| Australia | \$45,000 – \$70,000 |

| China | \$8,000 – \$15,000 (skilled role) |

Prime’s production base in China allows us to keep labor costs reasonable while maintaining high skills and strong output. This gives our clients better pricing without sacrificing performance.

Conclusion

Sheet metal fabrication requires skill—but with the right team, it’s highly reliable.

Want a partner that simplifies tough metal jobs? Prime delivers custom sheet metal and CNC parts with speed, quality, and ISO-certified precision. Contact us now for a free quote and expert support—your drawings, our experience.