Is Titanium the Strongest Metal on Earth?

Titanium sounds powerful—but is it the ultimate choice? Let’s uncover the truth together.

Titanium is strong and light, ideal for many industries. However, it’s not the strongest metal. Metals like tungsten and chromium outperform it in specific areas.

Titanium brings unmatched versatility in aerospace and medical fields. But buyers often wonder: is it truly the strongest? Let’s explore comparisons and smarter material choices.

Table of Contents

- What metal is stronger than titanium?

- What is the strongest metal in the world?

- Is titanium stronger than diamond?

- What is the strongest material on Earth?

- FAQs

- Contact Prime

What metal is stronger than titanium?

Titanium offers a great balance, but it’s not unmatched. Some metals beat it in strength or hardness.

Tungsten tops the list in tensile strength, while chromium leads in hardness. Titanium excels in strength-to-weight ratio.

| Metal | Tensile Strength (MPa) | Hardness (Mohs) | Density (g/cm³) |

|---|---|---|---|

| Titanium | \~1000 | 6 | 4.5 |

| Tungsten | \~1510 | 7.5 | 19.25 |

| Chromium | \~418 | 8.5 | 7.15 |

| Alloy Steel | \~1500+ | 6–7 | 7.8 |

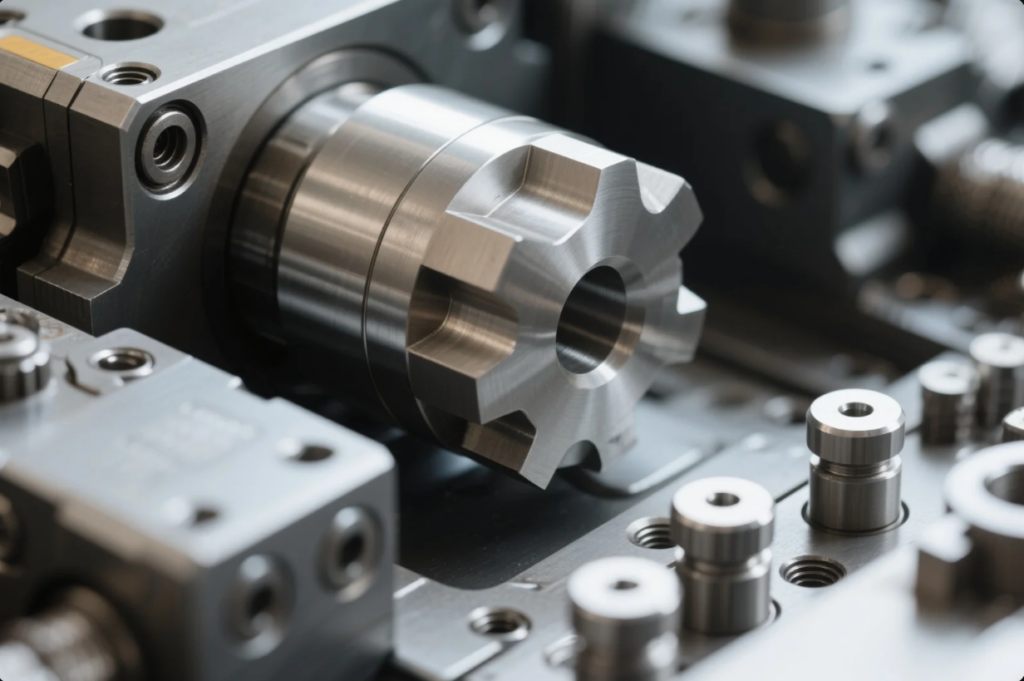

When sourcing materials for custom stamping parts or precision CNC machining, I often evaluate strength, corrosion resistance, and weight. Titanium is ideal when lightness matters—but if you’re focused purely on tensile performance, tungsten or alloyed steel could be more suitable options.

What is the strongest metal in the world?

Most assume titanium is the strongest. But the crown actually goes to tungsten.

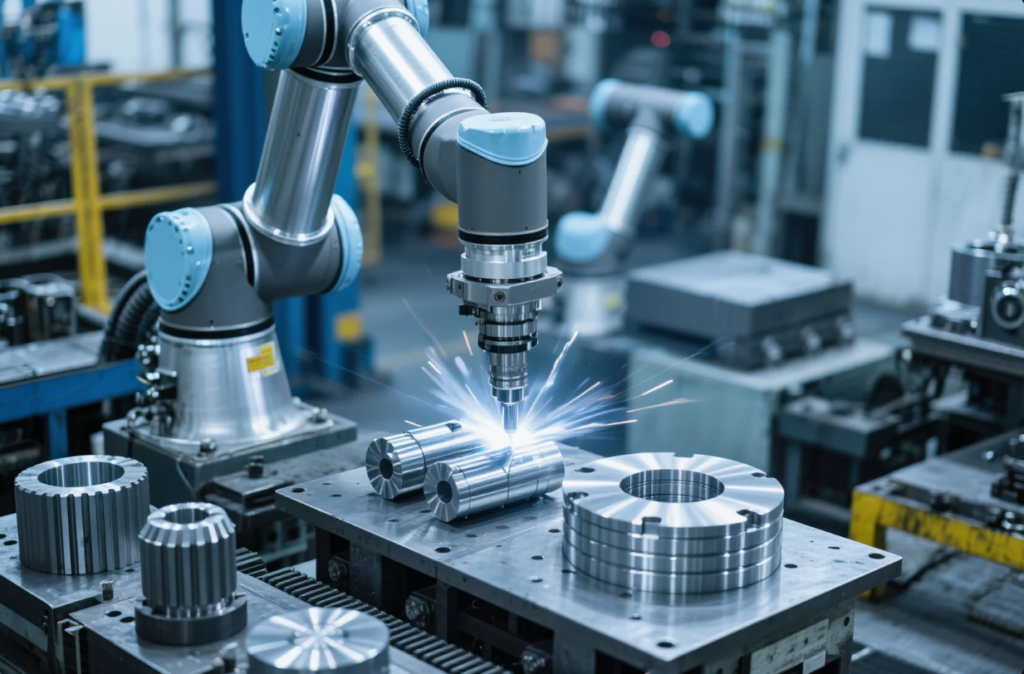

Tungsten has the highest tensile strength among all naturally occurring metals. It’s incredibly dense, heat-resistant, and wear-resistant, making it essential for military armor, tool dies, and drilling applications.

| Application | Preferred Metal | Reason |

|---|---|---|

| Aerospace Frames | Titanium | Lightweight, corrosion resistant |

| Tooling & Dies | Tungsten | Superior strength and density |

| Pipelines | Steel Alloys | Cost-efficient, high fatigue life |

In heavy machining, tungsten often outperforms titanium under pressure. NASA’s materials research highlights tungsten’s extreme temperature tolerance—one of the reasons it’s used in spacecraft and nuclear applications.

Is titanium stronger than diamond?

Strength and hardness aren’t the same. Titanium is strong and flexible, while diamond is brittle but the hardest known natural material.

Titanium bends under stress. Diamond breaks.

| Property | Titanium | Diamond |

|---|---|---|

| Type | Metal | Crystal |

| Hardness (Mohs) | 6 | 10 |

| Ductility | High | Very Low |

| Ideal Use | Structural parts | Cutting, polishing |

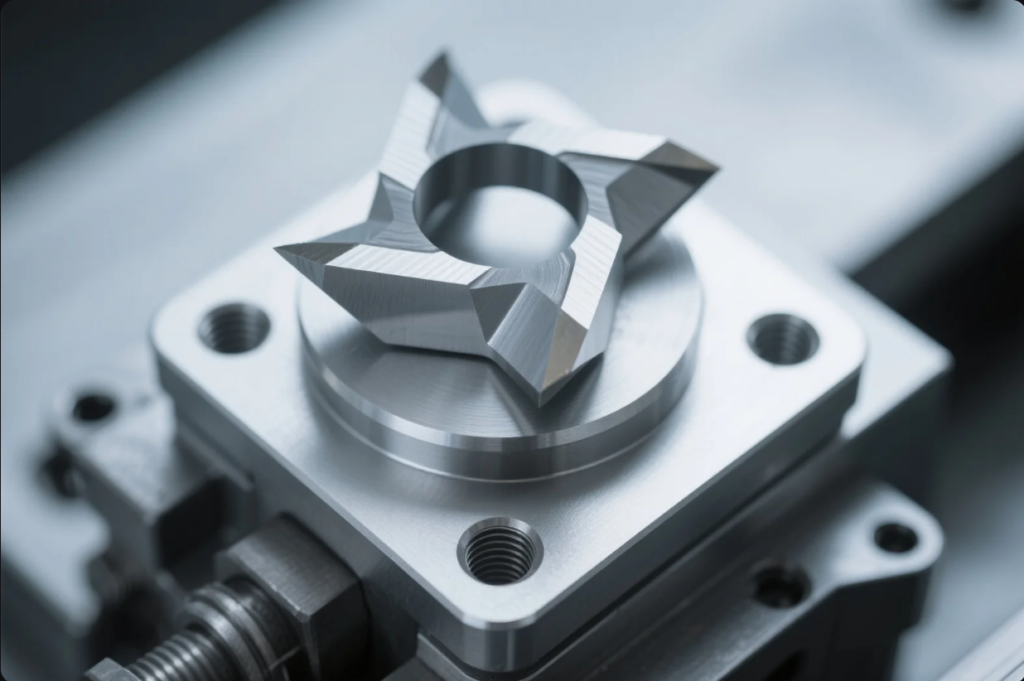

Though titanium can’t scratch a diamond, it can take stress better. In our projects involving aerospace-grade CNC titanium parts, clients choose titanium for its reliability and toughness under extreme conditions—not hardness.

If you’re curious about how diamond and titanium compare in industrial use, see this MakeItFrom technical comparison.

What is the strongest material on Earth?

Titanium is powerful—but the title of “strongest material” goes to graphene.

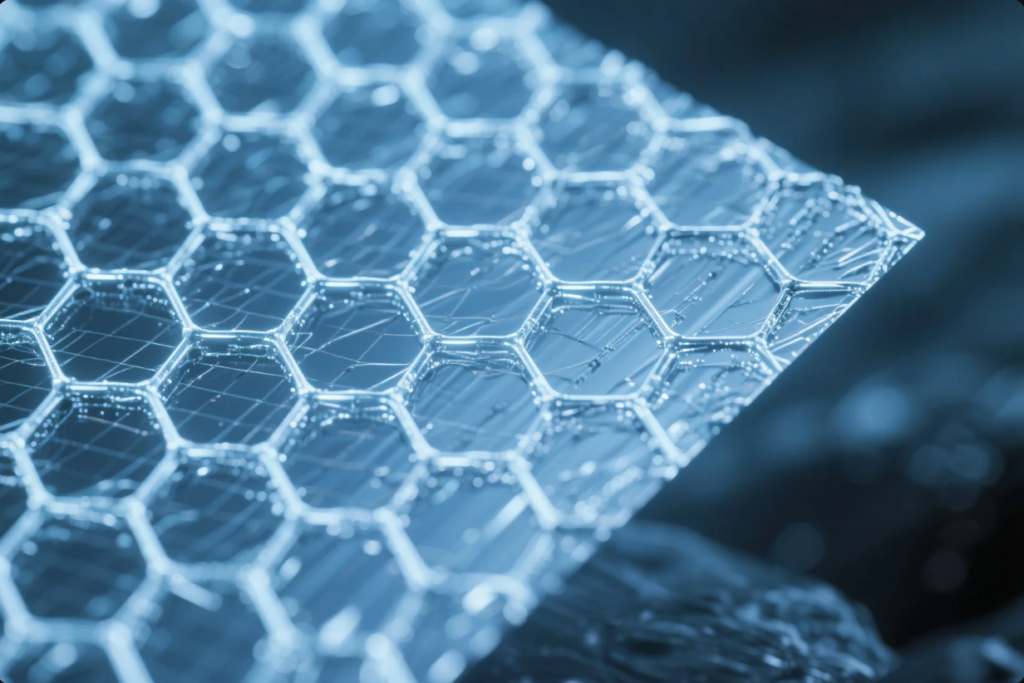

Graphene is over 100 times stronger than steel, even though it’s just one atom thick. That makes it the strongest substance ever tested.

| Material | Structure | Tensile Strength | Practical Use Today |

|---|---|---|---|

| Titanium | Bulk metal | \~1000 MPa | Aerospace, medical |

| Diamond | Crystal lattice | Extremely high | Cutting tools |

| Graphene | 1-atom layer | >130 GPa | Research, electronics |

While graphene isn’t yet widely used in manufacturing, it’s the focus of intense research. MIT and Manchester University have both demonstrated its strength and potential in composite materials and flexible electronics.

Still, for everyday parts like ISO-certified casting components or precision fasteners, titanium remains far more accessible.

FAQs

1. Is titanium stronger than stainless steel?

Titanium has better corrosion resistance and lower density, while stainless steel can be harder and cheaper. EngineersGarage explains further.

2. Can titanium handle high heat?

Yes. Titanium alloys withstand up to 600°C, perfect for exhausts and aerospace. Timet confirms this.

3. Is titanium good for CNC parts?

Absolutely. It’s machinable, durable, and corrosion-resistant. Modern Machine Shop explains why it’s favored in CNC machining.

4. Is Prime ISO-certified?

Yes. We are ISO 9001 certified, with over 20 years in global B2B export.

5. What industries rely on titanium?

Aerospace, medical implants, marine, automotive, and more. Titanium.org offers industry insights.

Contact Prime

We’re ready to help you select the right material—be it titanium, tungsten, or alloy steel.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

We offer:

- Free technical consultation and quotes

- ISO-certified custom manufacturing

- 10 in-house production lines

- Competitive pricing and global shipping

- Custom packaging for safe delivery

Let’s bring your next project to life with precision and reliability.

Conclusion

Titanium is strong, but not the strongest. Choosing wisely depends on your project’s true needs.