Mastering Fasteners: Types, Applications, and Innovations in 2025

Introduction

In the intricate world of manufacturing and construction, fasteners represent the unsung heroes that literally hold our modern infrastructure together. From the towering skyscrapers that define city skylines to the sophisticated electronics in our pockets, fasteners play a critical role in ensuring structural integrity, operational reliability, and product longevity. As we navigate through 2025, the fastener industry continues to evolve at an unprecedented pace, driven by technological advancements, material innovations, and changing market demands.

The evolution of fastener technology has been remarkable, transforming from simple mechanical components to sophisticated engineered solutions that address complex assembly challenges across diverse industries. Today\’s fasteners are not merely joining elements but precision-engineered components designed to withstand specific environmental conditions, mechanical stresses, and performance requirements. This evolution reflects broader trends in manufacturing, where quality, efficiency, and sustainability have become paramount considerations.

This comprehensive guide aims to provide manufacturing engineers and procurement professionals with actionable insights into the diverse world of fasteners. We will explore the various types and classifications of fasteners, examine their industry-specific applications, delve into the latest manufacturing technologies and material innovations, discuss quality control and standardization practices, and analyze future trends and challenges shaping the fastener industry in 2025 and beyond.

By mastering the fundamentals of fastener selection, application, and innovation, professionals can make informed decisions that enhance product performance, reduce costs, and drive competitive advantage in an increasingly complex global marketplace. Whether you\’re designing aerospace components, sourcing automotive parts, or managing construction projects, understanding the nuances of modern fastening systems is essential for success in today\’s manufacturing environment.

Join us as we unscrew the complexities of the fastener world and provide you with the knowledge needed to secure your projects with confidence and precision.

Understanding Fastener Types and Classifications

In the world of manufacturing and engineering, fasteners serve as the fundamental building blocks that ensure structural integrity and functionality across countless applications. Understanding the diverse range of fastener types, their unique characteristics, and appropriate applications is essential for making informed decisions in design, procurement, and maintenance processes. This section provides a comprehensive overview of the major fastener categories and their specialized variants as they exist in 2025.

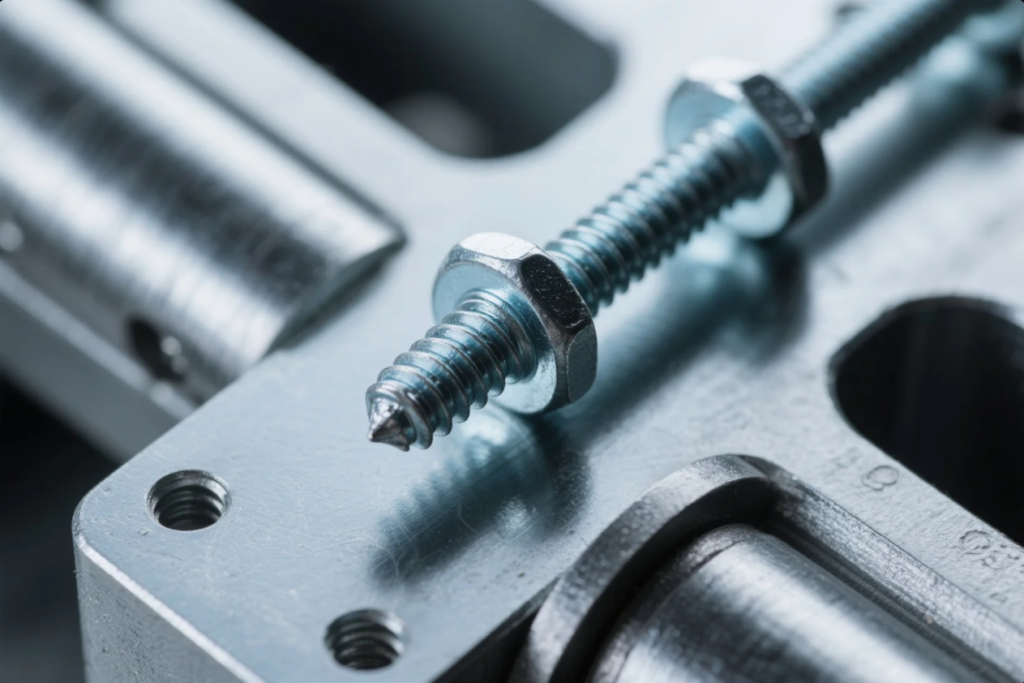

Bolts and Their Variations

Bolts represent one of the most common and versatile fastener types, characterized by their threaded shafts and heads designed to be paired with nuts for creating secure mechanical joints. The evolution of bolt technology has led to numerous specialized variants, each engineered for specific applications and performance requirements.

Hex Bolts

Hex bolts feature a six-sided head that provides excellent grip for wrenches and other tools, making them ideal for applications requiring precise torque control. In 2025, advanced manufacturing techniques have improved the dimensional accuracy and surface finish of hex bolts, enhancing their performance in critical applications across construction, machinery, and heavy equipment sectors.

Carriage Bolts

Distinguished by their smooth, rounded heads and square necks, carriage bolts are designed to prevent rotation when tightened, making them particularly valuable in wood-to-metal connections. Recent innovations have introduced composite carriage bolts that combine the traditional design with enhanced corrosion resistance and reduced weight, expanding their utility in outdoor and marine applications.

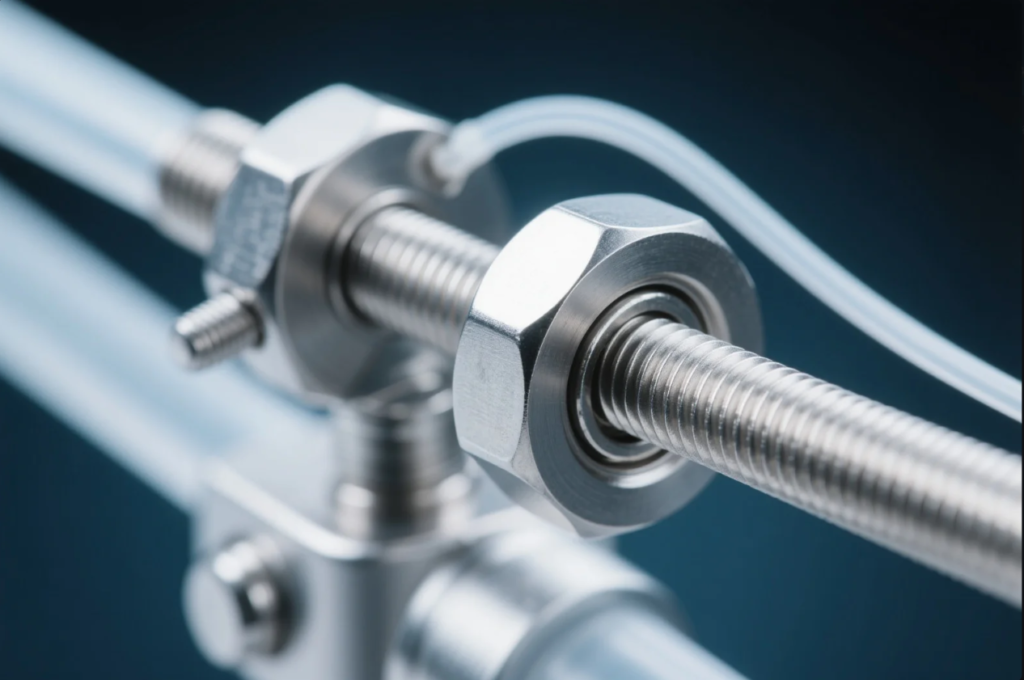

U-Bolts

U-shaped with threaded ends, these specialized fasteners excel at securing pipes, tubes, and round objects to structural members. The latest U-bolt designs incorporate advanced coatings and material formulations that significantly extend service life in exposed environments, addressing a long-standing challenge in infrastructure and utility applications.

Eye Bolts

Featuring a looped head designed for attaching cables, chains, or ropes, eye bolts play a crucial role in lifting, rigging, and securing operations. Recent developments include load-sensing eye bolts that incorporate embedded sensors to monitor tension and provide real-time data on structural loads, enhancing safety in critical lifting applications.

J-Bolts

With their J-shaped design, these fasteners are commonly used for anchoring objects to concrete or masonry. The latest generation of J-bolts features improved thread designs and material compositions that enhance pull-out resistance and long-term stability, particularly important in seismic zones and high-stress applications.

Flange Bolts

Incorporating an integrated washer-like flange under the head, these bolts distribute load over a wider area, reducing the risk of material damage and loosening. Recent advancements have introduced self-sealing flange bolts that incorporate elastomeric elements to provide vibration damping and fluid sealing capabilities in a single component.

Structural Bolts

Engineered specifically for high-strength structural connections in buildings, bridges, and infrastructure, these bolts meet rigorous standards for tensile strength and fatigue resistance. In 2025, the latest structural bolts incorporate advanced alloys and heat treatments that deliver unprecedented strength-to-weight ratios, enabling more efficient and sustainable structural designs.

Screws and Their Applications

Unlike bolts, screws typically create their own threading in the material and don\’t require nuts for fastening. The diverse family of screws has evolved to address specific material interactions and application requirements across numerous industries.

Wood Screws

Designed with sharp points and deep threads, wood screws efficiently penetrate and secure wooden components. Recent innovations include composite wood screws with carbon fiber reinforcement that offer superior holding power with minimal risk of splitting, addressing a common challenge in hardwood applications.

Sheet Metal Screws

Self-tapping screws designed specifically for thin metal applications, these fasteners create their own threads as they\’re driven. The latest generation features optimized thread geometries that reduce driving torque while increasing pull-out strength, enhancing both installation efficiency and joint reliability.

Machine Screws

Precision-manufactured with uniform threading for use with pre-tapped holes or nuts, machine screws are essential in mechanical assemblies and equipment manufacturing. Recent advancements include micro-precision machine screws with nanometer-level tolerances for use in miniaturized electronics and medical devices.

Drywall Screws

With their bugle-shaped heads and sharp points, drywall screws are optimized for securing gypsum board to wood or metal framing. The latest designs incorporate corrosion-resistant coatings and improved thread patterns that enhance holding power while minimizing panel damage, addressing key performance issues in construction applications.

Deck Screws

Engineered for outdoor applications, deck screws feature corrosion-resistant coatings and materials to withstand exposure to moisture and temperature fluctuations. Recent innovations include composite deck screws with enhanced UV stability and self-countersinking features that improve installation efficiency and aesthetic finish.

Masonry Screws

Designed for direct installation into concrete, brick, and stone, these hardened screws eliminate the need for separate anchors in many applications. The latest masonry screws incorporate carbide tips and optimized thread designs that reduce installation torque while increasing holding power in various masonry substrates.

Self-Drilling Screws

Combining drilling and fastening functions, these screws feature integrated drill points that eliminate the need for pre-drilling in many applications. Recent advancements include multi-material self-drilling screws capable of efficiently penetrating dissimilar materials in a single operation, streamlining assembly processes in manufacturing and construction.

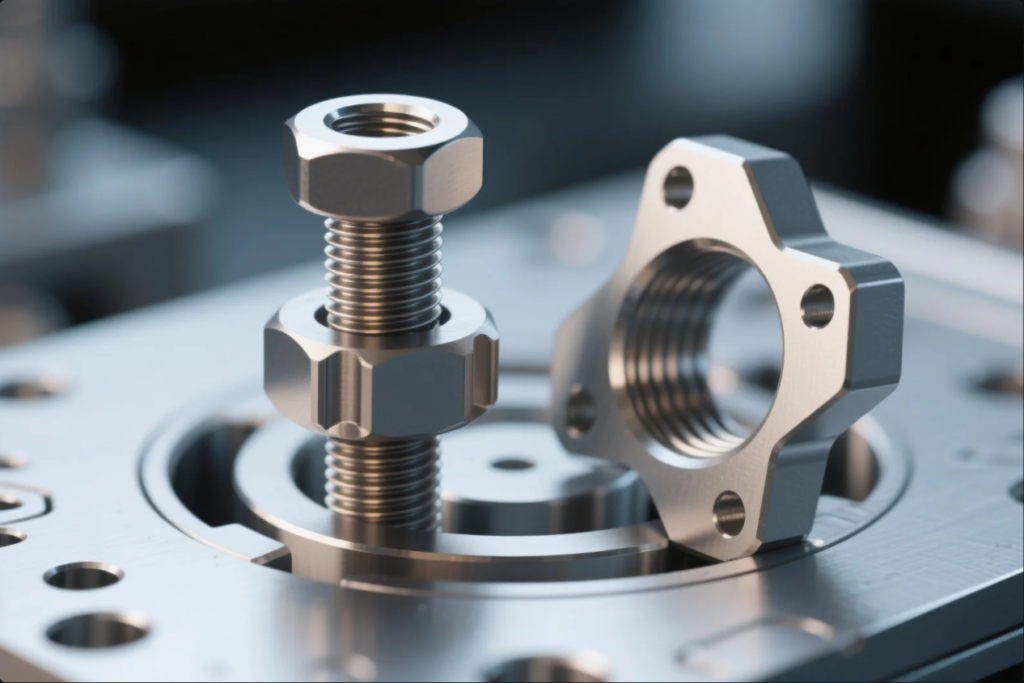

Nuts and Their Specialized Functions

Nuts work in conjunction with bolts and threaded rods to create secure mechanical joints. The diverse range of nut designs addresses specific performance requirements related to vibration resistance, load distribution, and installation accessibility.

Hex Nuts

The standard six-sided nuts represent the most common type, compatible with hex bolts and threaded rods across numerous applications. Recent innovations include gradient-hardened hex nuts that combine a tough exterior with a more ductile core, enhancing both durability and fatigue resistance in dynamic loading conditions.

Lock Nuts

Designed to resist loosening under vibration and dynamic loading, lock nuts incorporate various mechanisms to maintain tension. The latest designs include smart lock nuts with embedded sensors that monitor preload and provide alerts when fastener tension falls below critical thresholds, enhancing safety in critical applications.

Wing Nuts

Featuring wing-like projections that enable hand tightening, these nuts facilitate tool-free assembly and disassembly. Recent advancements include ergonomically optimized wing designs and hybrid materials that improve grip comfort while maintaining strength and durability in frequent-access applications.

T-Nuts

With their T-shaped design, these nuts embed into materials (typically wood) to provide strong threaded connections. The latest T-nut designs incorporate improved prongs and flanges that enhance pull-through resistance while minimizing damage to the parent material, addressing key performance limitations in furniture and fixture applications.

Coupling Nuts

Elongated nuts with internal threads, coupling nuts join threaded rods or bolts to create extended fastening systems. Recent innovations include adjustable coupling nuts with integrated tensioning mechanisms that simplify alignment and load balancing in structural applications.

Flange Nuts

Similar to flange bolts, these nuts incorporate an integrated washer surface to distribute load and prevent damage to mating surfaces. The latest designs feature optimized flange geometries and surface treatments that enhance load distribution while reducing the risk of galling in high-stress applications.

Washers and Their Importance

Often overlooked but critically important, washers distribute fastener loads, prevent surface damage, provide sealing functions, and enhance vibration resistance in mechanical joints.

Flat Washers

The most common type, flat washers distribute fastener loads over a wider area to prevent surface damage and improve joint stability. Recent advancements include composite flat washers with integrated damping layers that absorb vibration and reduce noise transmission in precision machinery and equipment.

Lock Washers

Designed to prevent fastener loosening, lock washers utilize various mechanisms to maintain tension under dynamic loading conditions. The latest designs incorporate advanced spring materials and optimized geometries that provide superior vibration resistance while minimizing stress concentration in the fastened components.

Spring Washers

With their curved or wave-like profiles, spring washers provide axial elasticity in fastened joints, accommodating thermal expansion and maintaining tension. Recent innovations include multi-layer spring washers that deliver precisely calibrated load-deflection characteristics for critical applications in aerospace and precision machinery.

Fender Washers

Featuring a large outer diameter relative to their hole size, fender washers distribute loads over especially wide areas for soft or brittle materials. The latest designs incorporate reinforced edges and optimized thickness profiles that enhance load distribution while minimizing weight and material usage.

Rivets and Their Unique Applications

Rivets create permanent mechanical joints through deformation, offering advantages in applications where access to both sides of the assembly is limited or where threaded fasteners might loosen over time.

Solid Rivets

The oldest and simplest rivet type, solid rivets require access to both sides of the joint for installation but provide exceptional strength and reliability. Recent advancements include advanced alloy solid rivets with improved fatigue resistance and corrosion protection, extending their utility in critical structural applications.

Blind Rivets

Designed for installation from one side only, blind rivets (often called "pop rivets") have revolutionized assembly processes across numerous industries. The latest designs incorporate structural blind rivets with enhanced shear and tensile strength approaching that of solid rivets, expanding their application in primary structural connections.

Drive Rivets

Installed by driving a pin through a tubular body, drive rivets combine ease of installation with good mechanical properties. Recent innovations include composite drive rivets that combine metallic and non-metallic components to provide electrical isolation while maintaining mechanical integrity.

Structural Rivets

Engineered specifically for high-strength applications in construction, transportation, and infrastructure, structural rivets meet rigorous standards for mechanical performance and durability. The latest designs incorporate advanced installation technologies that ensure consistent preload and joint quality while reducing installation time and cost.

Specialty Fasteners and Emerging Categories

Beyond the traditional categories, the fastener industry continues to evolve with specialized solutions addressing unique application requirements and emerging technologies.

Security Fasteners

Designed to resist tampering and unauthorized removal, security fasteners incorporate specialized drive features that require matching tools for installation and removal. Recent innovations include smart security fasteners with embedded authentication technologies that provide digital verification of authorized access and maintenance activities.

Insulated Fasteners

Engineered to prevent electrical conductivity between components, insulated fasteners incorporate non-conductive materials or coatings. The latest designs feature advanced composite constructions that combine excellent electrical isolation with high mechanical strength and temperature resistance.

Captive Fasteners

Designed to remain attached to the assembly when loosened, captive fasteners prevent loss and simplify maintenance operations. Recent advancements include tool-free captive fasteners with integrated retention mechanisms that enable rapid assembly and disassembly in field service applications.

Micro-Fasteners

With the continuing miniaturization of electronics and medical devices, micro-fasteners with dimensions measured in fractions of a millimeter have become increasingly important. The latest manufacturing technologies enable production of precision micro-fasteners with nanometer-level tolerances and surface finishes, supporting advances in miniaturized technology.

Bio-Compatible Fasteners

Developed specifically for medical implants and devices, bio-compatible fasteners utilize materials and coatings that interact safely with human tissues. Recent innovations include resorbable fasteners that provide temporary mechanical support before being safely absorbed by the body, eliminating the need for removal procedures.

Smart Fasteners

Representing the cutting edge of fastener technology in 2025, smart fasteners incorporate sensors, communication capabilities, and even active elements that monitor and report on joint conditions. These advanced fasteners enable real-time monitoring of critical connections in aerospace, infrastructure, and high-value equipment, enhancing safety and enabling predictive maintenance strategies.

Understanding this diverse ecosystem of fastener types and their specific applications provides the foundation for effective fastener selection and application across industries. As we continue through this guide, we\’ll explore how these various fastener types are applied in specific industry contexts and examine the latest manufacturing technologies and material innovations driving the fastener industry forward in 2025.

Industry-Specific Applications and Selection Guidelines

The selection of appropriate fasteners is a critical decision that varies significantly across industries, each with unique requirements, standards, and operational challenges. This section explores how different sectors approach fastener selection and application, providing practical guidelines for engineers and procurement professionals working in these specialized fields.

Aerospace and Aviation Fastener Requirements

The aerospace industry represents perhaps the most demanding environment for fasteners, where failure is simply not an option. Aircraft fasteners must withstand extreme temperature fluctuations, constant vibration, high stress loads, and potential corrosion while maintaining minimal weight.

Critical Performance Requirements

Aerospace fasteners must meet exceptional standards for:

- Strength-to-weight ratio: Advanced titanium alloys, high-strength aluminum, and specialized steel alloys dominate this sector, offering maximum strength with minimal mass.

- Fatigue resistance: With aircraft experiencing thousands of pressurization cycles and vibration events, fasteners must maintain integrity under repeated stress cycles.

- Temperature stability: From the extreme cold of high altitudes to the heat generated by engines, aerospace fasteners must maintain performance across temperature ranges from -65°F to over 2000°F in some applications.

- Corrosion resistance: Exposure to various environments worldwide necessitates superior corrosion protection through advanced materials and coatings.

Certification and Traceability

In 2025, aerospace fasteners adhere to stringent certification requirements including:

- AS9100 quality management standards

- Complete material and manufacturing traceability

- Non-destructive testing (NDT) verification

- Lot-specific certification documentation

Selection Guidelines

When selecting fasteners for aerospace applications, engineers must consider:

- Specific airframe or engine manufacturer requirements

- Compatibility with composite materials, which now constitute over 50% of modern aircraft structures

- Electrical bonding requirements to manage lightning strikes and static discharge

- Installation accessibility and maintenance considerations

- Weight optimization without compromising safety margins

Automotive Industry Fastening Solutions

The automotive sector balances high-volume production requirements with increasingly stringent performance, weight, and sustainability targets. In 2025, automotive fasteners must support the industry\’s transition toward electric vehicles, lightweight materials, and automated assembly processes.

Engine and Powertrain Applications

Despite the growth of electric vehicles, internal combustion engines remain significant and require specialized fasteners that can withstand:

- High temperatures (up to 650°F in some applications)

- Constant vibration and thermal cycling

- Exposure to oils, fuels, and other automotive fluids

- Precise torque requirements for critical components

Electric vehicle powertrains present different challenges, with fasteners needing to:

- Provide reliable electrical isolation where required

- Maintain performance despite electromagnetic fields

- Accommodate the unique thermal management requirements of battery systems

Body and Structural Applications

Modern automotive structures increasingly utilize:

- Self-piercing rivets for joining dissimilar materials

- Flow-drill screws that create their own holes in multiple layers

- Structural adhesives in combination with mechanical fasteners

- Lightweight composite-compatible fastening systems

Selection Guidelines

Automotive engineers should consider:

- Assembly process compatibility (manual, robotic, or automated installation)

- Cycle time impact on production efficiency

- Serviceability requirements for maintenance and repair

- Galvanic compatibility between fasteners and increasingly diverse substrate materials

- Global sourcing and standardization to support worldwide manufacturing operations

Construction and Structural Engineering Applications

The construction industry relies on fasteners that can withstand decades of environmental exposure while maintaining structural integrity. In 2025, construction fasteners must also address increasing focus on sustainability, seismic performance, and installation efficiency.

Structural Connections

Primary structural connections in buildings and infrastructure utilize:

- High-strength structural bolts meeting ASTM F3125 standards

- Direct tension indicators for reliable preload verification

- Specialized anchoring systems for concrete and masonry

- Moment-resistant connection systems for seismic applications

Exterior and Environmental Applications

Fasteners exposed to weather and environmental factors require:

- Enhanced corrosion protection through hot-dip galvanizing, mechanical galvanizing, or specialized coatings

- UV-resistant materials for long-term outdoor performance

- Thermal movement accommodation to prevent loosening or material damage

- Compatibility with pressure-treated lumber and other chemically treated building materials

Selection Guidelines

Construction professionals should evaluate:

- Load requirements (shear, tension, combined loading)

- Environmental exposure conditions

- Expected service life of the structure

- Installation accessibility and equipment requirements

- Code compliance and inspection requirements

- Sustainable and recyclable material options

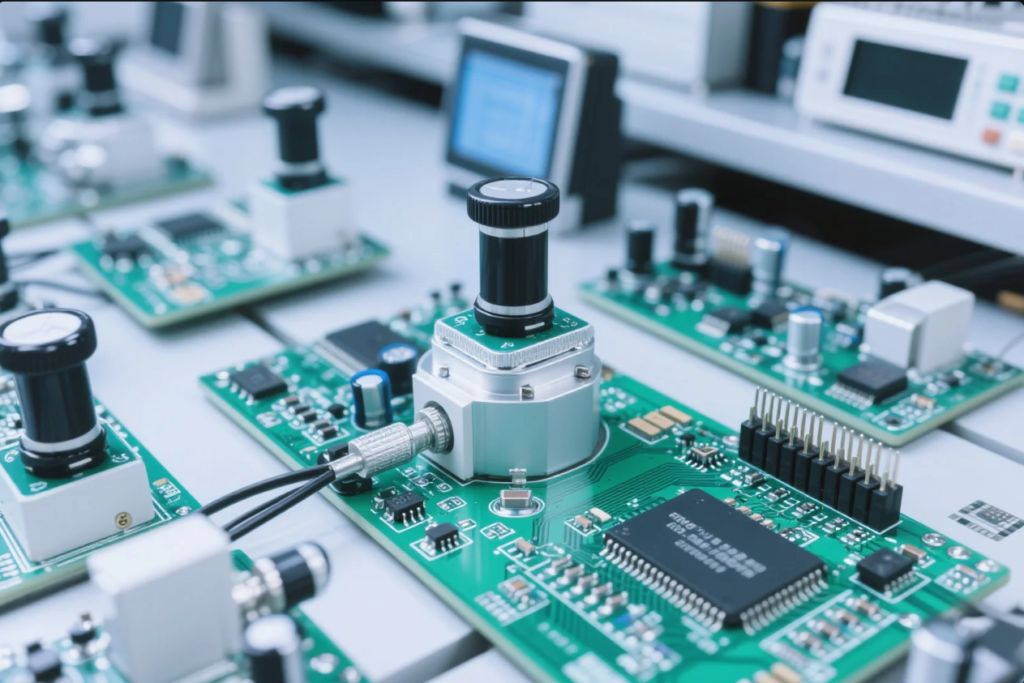

Electronics and Precision Equipment Fastening

The electronics industry presents unique challenges with miniaturization trends, thermal management requirements, and the need for precision assembly and disassembly. In 2025, electronics fasteners must accommodate increasingly dense component packaging while facilitating efficient manufacturing.

Miniaturized Fastening Solutions

Modern electronics rely on:

- Micro-screws with thread diameters as small as 0.6mm

- Specialized thread designs that achieve maximum holding power in minimal material

- Non-magnetic fastener options for sensitive components

- Heat-dissipating fasteners that serve dual purposes

Circuit Board and Component Mounting

PCB assembly utilizes:

- Standoffs and spacers for component elevation and airflow

- Self-clinching fasteners that create strong threads in thin materials

- Spring-loaded fasteners for components requiring thermal expansion accommodation

- Electrically isolated mounting systems where required

Selection Guidelines

Electronics engineers should consider:

- Space constraints and component density

- Thermal management requirements

- Electromagnetic interference (EMI) shielding needs

- Assembly and disassembly frequency

- Automated installation compatibility

- Electrostatic discharge (ESD) risks during installation

Marine and Offshore Environment Applications

Marine environments represent some of the most challenging conditions for fasteners, with constant exposure to moisture, salt, and in some cases, extreme pressures. In 2025, marine fasteners must deliver exceptional corrosion resistance while maintaining structural integrity.

Corrosion-Resistant Solutions

Marine applications typically require:

- High-grade stainless steels (316, 904L, or super duplex)

- Silicon bronze or specialized copper alloys for specific applications

- Titanium fasteners for critical or weight-sensitive components

- Advanced multi-layer coating systems for carbon steel fasteners

Specialized Marine Applications

Unique marine requirements include:

- Pressure-resistant fasteners for submersible applications

- Vibration-resistant systems for propulsion components

- Galvanically compatible fasteners to prevent accelerated corrosion

- Anti-fouling materials or coatings for submerged components

Selection Guidelines

Marine engineers should evaluate:

- Depth of immersion and pressure requirements

- Galvanic compatibility with adjacent materials

- Expected service life and maintenance intervals

- Cathodic protection system interaction

- Regulatory compliance for specific vessel types or offshore structures

Medical Device and Healthcare Industry Applications

The medical sector demands fasteners that combine absolute reliability with biocompatibility, sterilization resistance, and in many cases, specialized functionality. In 2025, medical fasteners increasingly incorporate advanced materials and innovative designs to enhance patient outcomes.

Implantable Device Fasteners

Medical implants utilize:

- Biocompatible materials such as titanium alloys, cobalt-chrome, and specialized stainless steels

- Surface treatments that promote osseointegration where bone attachment is desired

- Non-magnetic options for MRI compatibility

- Resorbable fasteners that dissolve safely after serving their purpose

External Medical Equipment

Equipment fasteners require:

- Resistance to repeated sterilization processes

- Smooth profiles to prevent fluid or contaminant trapping

- Easy cleaning and disinfection

- Tamper-resistant designs where appropriate

Selection Guidelines

Medical device engineers should consider:

- Biocompatibility requirements for the specific application

- Sterilization method compatibility

- Required service life (permanent vs. temporary)

- Imaging compatibility (CT, MRI, X-ray)

- Regulatory approval implications of fastener selection

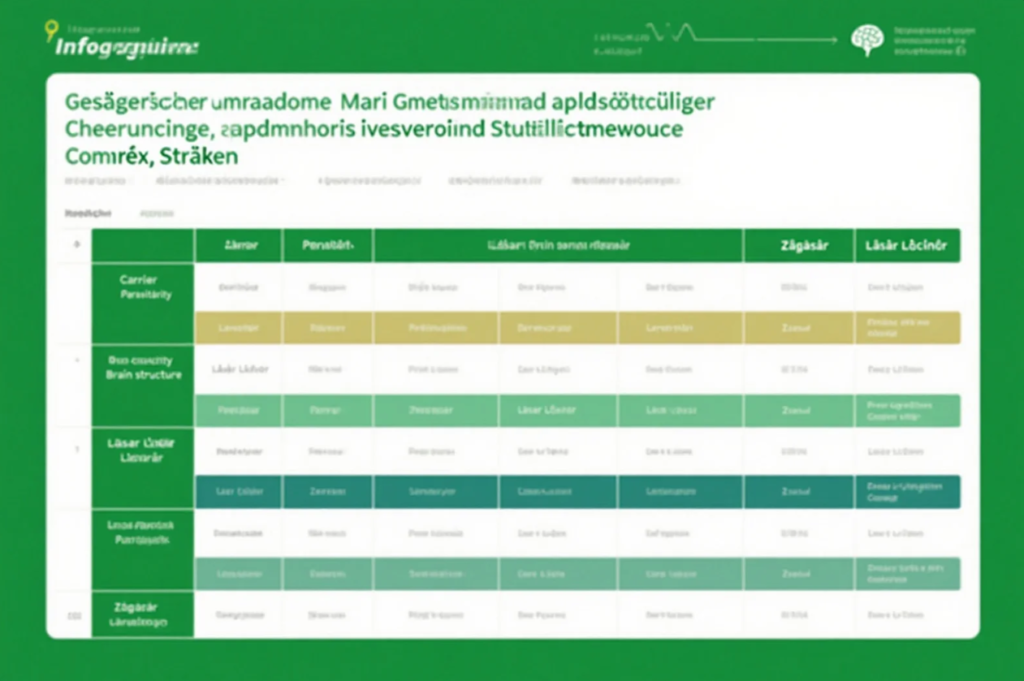

Selection Criteria Matrix for Different Industry Applications

To facilitate appropriate fastener selection across industries, the following matrix provides a structured approach to evaluating key requirements:

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Aerospace | Titanium, Inconel, high-strength aluminum | Fatigue resistance, weight, temperature stability | AS9100, NASM, NAS | Smart monitoring fasteners, composite-compatible designs | ||||||

| Automotive | Medium carbon steel, alloy steel, aluminum | Cost efficiency, automated installation, vibration resistance | ISO/TS 16949, SAE | Multi-material joining solutions, weight reduction | ||||||

| Construction | Structural steel, stainless steel, galvanized steel | Corrosion resistance, load capacity, installation efficiency | ASTM, AISC, ICC | Sustainable materials, seismic performance enhancement | ||||||

| Electronics | Stainless steel, brass, aluminum, engineered plastics | Miniaturization, thermal management, precision | IPC, JEDEC | Heat-dissipating designs, EMI shielding integration | ||||||

| Marine | 316/316L stainless, silicon bronze, titanium | Corrosion resistance, pressure tolerance, vibration resistance | ASTM, ABS, DNV | Advanced coating systems, composite compatibility | ||||||

| Medical | Titanium, cobalt-chrome, PEEK, resorbable polymers | Biocompatibility, imaging compatibility, functionality | ISO 13485, FDA, ASTM F138 | Smart implantable fasteners, infection-resistant materials |

Best Practices for Fastener Selection Across Industries

Regardless of industry, certain universal principles apply to fastener selection:

1. Understand the Complete Application Environment

- Operating temperature range

- Exposure to chemicals, moisture, or corrosive elements

- Dynamic loads and vibration conditions

- Installation and maintenance accessibility

- Expected service life

2. Consider the Total Cost of Ownership

- Initial fastener cost

- Installation time and labor requirements

- Specialized tool requirements

- Maintenance and replacement frequency

- Failure consequences and associated risks

3. Validate Performance Through Testing

- Prototype testing under actual or simulated conditions

- Accelerated life testing where appropriate

- Failure mode analysis

- Statistical process control during production

4. Maintain Documentation and Traceability

- Material certifications

- Lot-specific test results

- Installation procedures and torque specifications

- Maintenance records and inspection protocols

5. Stay Current with Evolving Standards and Technologies

- Industry-specific standard updates

- New material developments

- Advanced coating and surface treatment options

- Innovative fastener designs addressing common challenges

By applying these industry-specific guidelines and best practices, engineers and procurement professionals can make informed fastener selections that enhance product performance, reliability, and cost-effectiveness across diverse applications. The next section will explore the latest manufacturing technologies and material innovations driving the fastener industry forward in 2025.

Manufacturing Technologies and Material Innovations in 2025

The fastener industry has undergone remarkable transformation in recent years, driven by advancements in manufacturing technologies, materials science, and increasing demands for performance, efficiency, and sustainability. This section explores the cutting-edge developments shaping fastener production in 2025, highlighting how these innovations are revolutionizing product capabilities and manufacturing processes.

Advanced Materials Science Breakthroughs

Material innovation represents one of the most significant areas of advancement in the fastener industry, with new alloys and composites delivering unprecedented combinations of strength, weight, corrosion resistance, and functionality.

Nanostructured Alloys

Nanostructured alloys represent a quantum leap in fastener material technology, featuring grain structures engineered at the nanometer scale to achieve exceptional mechanical properties.

- Ultra-high-strength steels with nanoscale grain refinement now achieve tensile strengths exceeding 2,000 MPa while maintaining adequate ductility, enabling smaller, lighter fasteners that maintain load-bearing capacity.

- Gradient nanostructures feature varying grain sizes throughout the fastener, with nanoscale grains at the surface for wear and corrosion resistance, transitioning to larger grains in the core for enhanced toughness and ductility.

- Self-healing capabilities have emerged in certain nanostructured alloys, where microscopic damage triggers localized reactions that effectively "repair" the material, extending fastener life in critical applications.

Advanced Composite Materials

Composite materials have evolved significantly, offering fastener designers unprecedented combinations of properties that cannot be achieved with traditional metals.

- Carbon fiber reinforced polymers (CFRP) are now being used for specialized fasteners in aerospace and high-performance automotive applications, offering exceptional strength-to-weight ratios and corrosion resistance.

- Metal matrix composites (MMCs) combine metal alloys with ceramic reinforcements to create fasteners with superior wear resistance, thermal stability, and specific strength for demanding applications.

- Hybrid composite fasteners integrate multiple materials in a single component, such as a metal core with composite outer layers, optimizing performance characteristics for specific applications.

Specialized Coatings and Surface Treatments

Surface engineering has advanced dramatically, with new coating technologies that enhance fastener performance across multiple dimensions.

- Diamond-like carbon (DLC) coatings provide exceptional hardness and low friction, reducing installation torque requirements while improving wear resistance.

- Ceramic-metallic (cermet) coatings combine ceramic hardness with metallic toughness, offering superior protection against both corrosion and mechanical damage.

- Self-lubricating coatings incorporate solid lubricants in a durable matrix, maintaining low friction throughout the fastener\’s service life without requiring additional lubrication.

- Antimicrobial surface treatments have gained importance in medical and food processing applications, with copper, silver, or zinc-infused coatings that actively inhibit bacterial growth.

Bio-based and Sustainable Materials

Environmental considerations have driven significant innovation in sustainable fastener materials.

- Bio-derived polymers from renewable sources now offer performance comparable to petroleum-based plastics for non-structural fastener applications, reducing carbon footprint.

- Recycled content alloys have been developed with carefully controlled processing to ensure mechanical properties match or exceed those of virgin materials, supporting circular economy initiatives.

- Biodegradable fasteners designed for temporary applications decompose safely after their useful life, eliminating the need for removal and reducing environmental impact.

Smart Manufacturing Integration

The integration of digital technologies, automation, and data analytics has transformed fastener production, improving quality, efficiency, and flexibility while reducing costs and environmental impact.

Internet of Things (IoT) in Production

IoT technologies have revolutionized fastener manufacturing by creating interconnected production environments where machines, materials, and processes communicate continuously.

- Real-time monitoring systems track critical parameters throughout the production process, from raw material properties to forming forces and heat treatment temperatures, ensuring consistent quality.

- Predictive maintenance algorithms analyze equipment performance data to forecast potential failures before they occur, minimizing unplanned downtime and optimizing maintenance schedules.

- Digital twins of production lines enable virtual simulation and optimization of manufacturing processes, accelerating innovation while reducing the cost and risk of physical changes.

Advanced Robotics and Automation

Robotics and automation have reached new levels of sophistication in fastener production, handling increasingly complex tasks with greater precision and flexibility.

- Collaborative robots (cobots) work alongside human operators, handling repetitive tasks while humans focus on quality control, problem-solving, and process improvement.

- Vision-guided robotics perform automated inspection and sorting, identifying subtle defects that might escape human detection and ensuring only conforming products reach customers.

- Flexible automation systems enable rapid changeovers between different fastener types and sizes, supporting efficient production of smaller batches to meet diverse customer requirements.

Artificial Intelligence and Machine Learning

AI and machine learning applications have transformed quality control, process optimization, and decision-making in fastener manufacturing.

- Adaptive process control systems continuously adjust manufacturing parameters based on real-time data and learned patterns, maintaining optimal quality despite variations in raw materials or environmental conditions.

- Defect prediction models identify potential quality issues before they occur by recognizing subtle patterns in process data that precede specific types of defects.

- Supply chain optimization algorithms balance multiple factors including cost, lead time, quality, and sustainability to make intelligent sourcing decisions in an increasingly complex global market.

3D Printing and Additive Manufacturing

Additive manufacturing technologies have evolved from prototyping tools to viable production methods for certain types of fasteners, offering unprecedented design freedom and efficiency for specialized applications.

Direct Metal Printing

Metal additive manufacturing has matured significantly, enabling the production of complex fasteners with internal features and optimized geometries that would be impossible to create using traditional methods.

- Laser powder bed fusion (LPBF) produces high-strength metal fasteners with exceptional precision, particularly valuable for custom or low-volume applications in aerospace and medical industries.

- Binder jetting technology has advanced to enable higher-volume production of metal fasteners with competitive costs for certain applications, particularly where complex geometries add significant value.

- Hybrid manufacturing systems combine additive and subtractive processes in a single machine, building the basic fastener shape through additive methods and then precision-machining critical surfaces to achieve required tolerances.

Composite Printing

Additive manufacturing of composite materials has opened new possibilities for lightweight, high-performance fasteners.

- Continuous fiber reinforcement techniques allow 3D-printed fasteners to incorporate unbroken carbon or glass fibers along load paths, dramatically improving strength in critical directions.

- Multi-material printing enables the creation of fasteners with different properties in different regions, such as rigid cores with flexible outer layers for improved sealing or vibration damping.

- Functionally graded materials (FGM) can be created through additive processes, with properties that transition gradually from one region to another, eliminating sharp interfaces that could become stress concentration points.

Rapid Prototyping and Custom Solutions

The speed and flexibility of additive manufacturing have transformed the development process for specialized fasteners.

- Iterative design optimization is accelerated through rapid prototyping, allowing engineers to test multiple versions of a fastener design in days rather than weeks or months.

- Digital inventory approaches replace physical stock of rarely-used specialty fasteners with on-demand production from stored digital designs, reducing inventory costs and obsolescence risk.

- Point-of-use manufacturing is emerging for certain applications, with compact 3D printers producing fasteners at the installation site to exact specifications, eliminating shipping time and costs.

Cold Forming and Precision Machining Advancements

Traditional manufacturing methods continue to evolve, with significant improvements in efficiency, precision, and capability for high-volume fastener production.

Multi-stage Cold Forming

Cold forming remains the most efficient production method for high-volume fasteners, with recent advances enhancing its capabilities and efficiency.

- Advanced die designs created through computational modeling optimize material flow during forming, reducing defects and extending tool life while enabling more complex geometries.

- Multi-material forming techniques allow the creation of fasteners with different materials in different regions, such as steel bodies with copper or aluminum heads for improved electrical conductivity.

- Precision control systems maintain tighter tolerances throughout the forming process, reducing variation and enabling the production of increasingly precise fasteners without secondary operations.

High-Precision CNC Machining

Computer numerical control (CNC) machining technologies have advanced to enable the efficient production of complex fasteners with exceptional precision.

- Multi-axis machining centers produce complex fasteners in a single setup, reducing handling and improving geometric accuracy while increasing production efficiency.

- Micro-machining capabilities have improved dramatically, enabling the production of extremely small fasteners with features measured in micrometers for electronics and medical applications.

- Hard material machining advancements allow direct machining of hardened materials that previously required grinding, improving efficiency and reducing production costs for high-strength fasteners.

Thread Rolling and Forming

Thread production technologies have evolved to create stronger, more precise threads with greater efficiency.

- Optimized thread profiles designed through finite element analysis provide improved fatigue resistance and load distribution while maintaining compatibility with standard tools.

- Controlled surface deformation during thread rolling creates beneficial compressive stresses that significantly improve fatigue life in critical applications.

- In-process monitoring systems verify thread quality during production, detecting and rejecting non-conforming parts before they enter the supply chain.

Surface Treatment and Coating Innovations

Surface treatments and coatings play an increasingly important role in fastener performance, with new technologies offering improved corrosion protection, reduced friction, and specialized functionality.

Advanced Corrosion Protection

Corrosion protection has advanced significantly beyond traditional plating and galvanizing methods.

- Multi-layer coating systems combine different materials to provide complementary protection mechanisms, such as a zinc base layer for sacrificial protection with an aluminum-rich topcoat for barrier protection.

- Sol-gel technologies create nanoscale ceramic coatings that provide exceptional corrosion resistance with minimal thickness, maintaining dimensional precision for threaded fasteners.

- Vapor-deposited coatings applied through physical or chemical vapor deposition (PVD/CVD) create extremely uniform, high-performance protective layers even on complex geometries.

Friction Control Coatings

Specialized coatings that precisely control friction characteristics have become increasingly important for critical fastening applications.

- Torque-tension optimized coatings provide consistent friction during installation, ensuring that applied torque translates reliably to fastener tension for more predictable joint performance.

- Dual-personality coatings offer low friction during installation followed by increased friction after tightening, combining easy assembly with excellent vibration resistance.

- Wear-compensating systems maintain consistent friction characteristics throughout multiple installation and removal cycles, important for fasteners in equipment requiring regular maintenance.

Functional Surface Modifications

Beyond traditional protective and decorative functions, fastener coatings now provide additional specialized capabilities.

- Electrically conductive coatings ensure reliable electrical connections in grounding applications or electronic assemblies, with consistent performance throughout the fastener\’s service life.

- Thermally enhanced surfaces improve heat transfer from fasteners to surrounding materials, important in electronics cooling and other thermal management applications.

- Adhesive-promoting treatments improve bonding between fasteners and adhesives or sealants, creating more reliable hybrid mechanical/chemical joints.

Bio-based and Sustainable Material Developments

Environmental considerations have driven significant innovation in sustainable fastener materials and manufacturing processes, responding to both regulatory requirements and market demand.

Renewable Source Materials

The use of materials derived from renewable sources has expanded beyond simple plastic fasteners to more sophisticated applications.

- High-performance bio-polymers derived from plant sources now offer mechanical properties suitable for structural applications, particularly in industries prioritizing sustainability.

- Natural fiber composites combine bio-based resins with reinforcements like flax, hemp, or bamboo fibers to create fasteners with reduced environmental impact and unique aesthetic qualities.

- Mycelium-based materials (derived from fungal structures) are emerging as biodegradable alternatives for temporary fastening applications in packaging and non-structural assemblies.

Recycled Content Integration

The use of recycled materials in fastener production has advanced significantly, with new technologies overcoming previous limitations.

- High-purity recycled metals processed through advanced sorting and refining techniques now meet stringent mechanical property requirements for critical fastener applications.

- Upcycled composite materials repurpose carbon or glass fibers recovered from end-of-life products into new high-value fasteners, reducing waste while maintaining performance.

- Closed-loop manufacturing systems recover and reuse production scrap within the same facility, minimizing waste and reducing the carbon footprint of fastener production.

Energy-Efficient Manufacturing

Energy consumption in fastener production has been reduced through process innovations and equipment upgrades.

- Induction heating systems replace conventional furnaces for heat treatment, providing more precise temperature control with significantly lower energy consumption.

- Servo-electric forming presses replace hydraulic systems, eliminating hydraulic fluid requirements while reducing energy consumption by up to 50%.

- Heat recovery systems capture and reuse thermal energy from manufacturing processes, reducing overall energy requirements and associated carbon emissions.

The manufacturing technologies and material innovations described in this section represent the cutting edge of fastener development in 2025. By leveraging these advancements, manufacturers can produce fasteners with unprecedented combinations of performance, efficiency, and sustainability to meet the evolving needs of diverse industries. The next section will explore quality control and standardization practices that ensure these advanced fasteners consistently meet or exceed performance expectations.

Quality Control and Standardization

In the fastener industry, quality control and standardization are not merely regulatory requirements but essential foundations for safety, reliability, and performance. As fastener applications become increasingly critical and specialized in 2025, the systems and standards governing their production and verification have evolved to ensure consistent excellence. This section explores the comprehensive quality assurance frameworks, testing methodologies, and standardization practices that define modern fastener manufacturing.

International Standards and Certifications

The global nature of fastener supply chains necessitates harmonized standards and certification systems that ensure consistency and interoperability across borders and industries.

ISO Standards Framework

The International Organization for Standardization (ISO) continues to provide the backbone of fastener standardization globally, with several key standards updated for 2025:

- ISO 898 series defines mechanical properties for steel fasteners, with recent updates addressing emerging high-strength materials and specialized applications.

- ISO 3506 series covers stainless steel fasteners, with expanded coverage of newer alloys and performance characteristics relevant to sustainable infrastructure and energy applications.

- ISO 9001:2025 represents the latest evolution of the quality management system standard, with enhanced emphasis on risk management, digital documentation, and supply chain integration.

- ISO 14001:2024 addresses environmental management systems, increasingly important as sustainability becomes a core consideration in fastener manufacturing.

Regional and Industry-Specific Standards

While ISO standards provide global consistency, regional and industry-specific standards address particular needs and regulatory requirements:

- ASTM International standards remain predominant in North America, with ASTM F3125 governing structural bolts and ASTM A193/A194 covering high-temperature applications.

- European Norms (EN) provide detailed specifications for fasteners used within the European Union, with harmonized standards supporting CE marking requirements.

- JIS (Japanese Industrial Standards) continue to influence fastener specifications throughout Asia, with particular emphasis on precision and consistency.

- Industry-specific standards such as aerospace (AS/NAS/NASM), automotive (IATF 16949), and medical (ISO 13485) impose additional requirements tailored to their unique applications.

Certification Systems and Requirements

Certification provides formal verification of compliance with standards, with several systems particularly relevant to fastener manufacturing:

- ISO 9001 certification remains fundamental, verifying that manufacturers maintain consistent quality management systems.

- Product certification schemes such as the CE mark in Europe and various industry-specific approvals provide assurance that fasteners meet relevant performance and safety standards.

- Laboratory accreditation under ISO/IEC 17025 ensures that testing facilities provide reliable and consistent results, critical for verifying fastener properties.

- Environmental certifications such as ISO 14001 and industry-specific sustainability standards are increasingly important as customers prioritize environmental responsibility.

Testing Methodologies and Quality Assurance

Fastener testing has evolved significantly, with advanced technologies enabling more comprehensive verification of properties and performance with greater efficiency and reliability.

Mechanical Testing Advancements

Mechanical testing verifies that fasteners can withstand the forces they will encounter in service:

- Automated tensile testing systems now provide high-throughput verification of strength properties, with digital data capture and analysis enhancing traceability and statistical process control.

- Fatigue testing has become more sophisticated, with accelerated test protocols that more accurately simulate real-world loading conditions while reducing test duration.

- Torque-tension relationship testing has improved with sensor-rich systems that provide detailed data on fastener behavior during installation, critical for applications where precise preload is essential.

- Impact and vibration resistance testing now incorporates multi-axis loading and environmental factors, better replicating the complex conditions fasteners experience in service.

Material Verification Techniques

Ensuring that fasteners are made from the correct materials with appropriate properties has become more sophisticated:

- Portable spectrometers enable rapid verification of material composition at receiving inspection or even in the field, reducing the risk of counterfeit or incorrect fasteners entering the supply chain.

- Microstructural analysis techniques have become more accessible, with automated systems that quickly assess grain structure, inclusions, and other features that influence fastener performance.

- Hardness mapping provides detailed information about property variations within fasteners, particularly important for components with selective hardening or complex geometries.

- Residual stress measurement techniques such as X-ray diffraction have become more practical for production environments, enabling verification of this critical but often overlooked property.

Non-Destructive Testing Advancements

Non-destructive testing (NDT) allows verification of fastener quality without rendering the components unusable:

- Advanced ultrasonic inspection can detect internal defects with greater sensitivity and speed than ever before, with automated systems capable of scanning thousands of fasteners per hour.

- Eddy current testing has evolved to detect surface and near-surface defects with improved reliability, particularly valuable for critical applications where surface integrity is essential.

- Digital radiography provides detailed internal images with lower radiation exposure and faster results than traditional X-ray methods, enhancing both safety and efficiency.

- Acoustic emission monitoring during proof loading can detect incipient failures that might not be visible through other inspection methods, providing an additional safety margin for critical applications.

Statistical Process Control and Quality Monitoring

Modern quality systems emphasize prevention rather than detection, with sophisticated monitoring and control systems:

- Real-time process monitoring captures data from throughout the manufacturing process, identifying trends and anomalies before they result in nonconforming products.

- Advanced statistical tools such as machine learning algorithms analyze complex patterns in process data, identifying subtle relationships that might escape traditional SPC methods.

- Digital thread traceability links raw material properties, process parameters, and finished product characteristics, enabling root cause analysis and continuous improvement.

- Automated inspection systems incorporating computer vision and AI can detect subtle defects with greater consistency than human inspectors, while maintaining comprehensive digital records.

Material Test Reports and Certification Documentation

Documentation provides the formal evidence of fastener quality and traceability, with systems evolving to enhance both reliability and efficiency.

Types of Certification Documents

Different levels of documentation address varying requirements for traceability and verification:

- Certificate of Conformance (CoC) provides basic assurance that fasteners meet specified requirements, typically without detailed test results.

- Material Test Reports (MTR) include actual test results for chemical composition and mechanical properties, essential for critical applications.

- First Article Inspection Reports (FAIR) document comprehensive verification of all characteristics for new or changed products, establishing a baseline for ongoing production.

- Production Part Approval Process (PPAP) documentation, common in automotive applications, provides systematic evidence that production processes can consistently meet all requirements.

Digital Documentation Systems

Paper certificates are increasingly giving way to digital systems that enhance security, accessibility, and integration:

- Blockchain-based certification provides tamper-evident documentation with distributed verification, reducing the risk of counterfeit certificates.

- Cloud-based documentation platforms enable secure sharing of certificates throughout the supply chain, with controlled access and version management.

- Digital signatures and authentication enhance document security while streamlining verification processes.

- Machine-readable formats enable automated verification and integration with customer quality systems, reducing administrative burden while improving reliability.

Certification Requirements by Industry

Documentation requirements vary significantly across industries, reflecting different risk profiles and regulatory frameworks:

- Aerospace typically requires comprehensive documentation including material traceability to heat lot, detailed dimensional inspection results, and specific process certifications.

- Automotive emphasizes statistical process data and PPAP documentation, focusing on process capability and consistency rather than individual fastener testing.

- Construction generally requires certification of conformance to relevant standards, with additional documentation for structural applications or specialized performance characteristics.

- Medical demands comprehensive documentation including biocompatibility testing, sterilization validation, and risk management records, particularly for implantable devices.

Traceability Systems and Batch Control

Traceability links finished fasteners to their raw materials, manufacturing processes, and test results, essential for quality assurance and risk management.

Raw Material to Finished Product Traceability

Complete traceability begins with raw materials and continues throughout the manufacturing process:

- Raw material certification provides the foundation, documenting the composition and properties of the starting material.

- Heat lot tracking maintains the connection between raw material batches and finished fasteners, essential for root cause analysis if issues arise.

- Process parameter recording documents the conditions under which fasteners were manufactured, enabling verification that all specifications were met.

- Finished product testing completes the chain, confirming that the final fasteners possess the required properties.

Marking and Identification Technologies

Physical marking of fasteners enables identification throughout their lifecycle:

- Head marking remains the most common identification method, with standardized codes indicating grade, manufacturer, and material.

- Direct part marking (DPM) technologies such as laser etching enable more detailed information to be permanently applied to fasteners without affecting performance.

- RFID and NFC integration in packaging or, for larger fasteners, in the components themselves, enables electronic identification and tracking.

- Serialization of individual high-value or critical fasteners provides the ultimate level of traceability, increasingly practical with advanced marking technologies.

Digital Traceability Solutions

Digital systems enhance traceability with improved accessibility, security, and integration:

- Manufacturing execution systems (MES) maintain comprehensive digital records of all production parameters and test results, linked to specific batches or individual fasteners.

- Supply chain traceability platforms extend visibility beyond individual manufacturers to encompass the entire value chain from raw material to end use.

- QR codes and digital links on packaging provide instant access to certificates and test results via mobile devices, simplifying verification in the field.

- Digital twin concepts are extending to fastener batches, with complete virtual representations of physical products and their manufacturing history.

Non-Destructive Testing Advancements

Non-destructive testing technologies have evolved significantly, enabling more comprehensive quality verification without sacrificing the tested components.

Automated Visual Inspection Systems

Computer vision and AI have transformed visual inspection processes:

- Multi-angle imaging captures comprehensive views of fasteners, detecting surface defects regardless of orientation.

- Deep learning algorithms identify subtle defects that might be missed by human inspectors or traditional machine vision systems.

- High-speed inspection systems can evaluate thousands of fasteners per hour with consistent criteria, eliminating human fatigue as a factor.

- Dimensional verification through optical measurement provides rapid, non-contact confirmation of critical dimensions and geometries.

Advanced Scanning Technologies

Beyond visual inspection, various scanning technologies provide insight into internal features and material properties:

- Computed tomography (CT) scanning has become more accessible for production environments, providing detailed three-dimensional images of internal features and defects.

- Terahertz imaging offers non-ionizing inspection capabilities for non-metallic components or coatings, filling a gap between X-ray and ultrasonic methods.

- Laser shearography detects subtle surface deformations that may indicate underlying defects or residual stress issues.

- Magnetic particle imaging has evolved with more sensitive detection systems and automated interpretation, enhancing reliability for ferromagnetic fasteners.

In-Line and Real-Time Inspection

Integration of inspection technologies directly into production lines enables immediate feedback and correction:

- In-line sensor arrays monitor critical parameters throughout the manufacturing process, providing real-time feedback for process control.

- Automated sorting systems immediately separate nonconforming products, preventing them from proceeding to subsequent operations or packaging.

- Continuous monitoring throughout the production process reduces reliance on final inspection, catching issues earlier when corrections are less costly.

- Digital integration between inspection systems and process controls enables automatic adjustments to maintain optimal quality.

Digital Quality Management Systems

Quality management has been transformed by digital technologies that enhance data collection, analysis, and application for continuous improvement.

Quality 4.0 Implementation

The concept of Quality 4.0 represents the integration of digital technologies into comprehensive quality management:

- IoT-enabled quality monitoring collects data from throughout the manufacturing process, providing unprecedented visibility into factors affecting product quality.

- Cloud-based quality platforms enable collaboration across locations and organizations, with secure sharing of specifications, test results, and improvement initiatives.

- Mobile quality applications bring quality management capabilities to the production floor, enabling real-time data collection and access to procedures and specifications.

- Integration with ERP and MES systems creates a seamless flow of quality information throughout the organization, supporting both operational and strategic decision-making.

Predictive Quality Analytics

Advanced analytics transform quality data from descriptive to predictive:

- Predictive defect models identify patterns in process data that precede quality issues, enabling preemptive action before defects occur.

- Supplier quality prediction analyzes historical performance and current indicators to forecast potential issues with incoming materials or components.

- Maintenance impact analysis predicts how equipment conditions will affect product quality, optimizing maintenance timing to prevent quality degradation.

- Customer feedback correlation links field performance data with manufacturing parameters, identifying subtle factors that influence real-world product performance.

Digital Twins for Quality Assurance

The digital twin concept has expanded to encompass quality aspects of products and processes:

- Process digital twins simulate manufacturing operations with quality parameters, enabling virtual testing of process changes before physical implementation.

- Product quality twins maintain comprehensive records of all quality characteristics for specific products or batches, accessible throughout the product lifecycle.

- Supply chain quality twins extend the concept across organizational boundaries, providing end-to-end visibility of quality factors.

- Predictive quality modeling uses digital twins to forecast how design or process changes might affect quality outcomes, supporting risk-based decision making.

The quality control and standardization practices described in this section represent the foundation of confidence in fastener performance across diverse and demanding applications. By embracing these advanced methodologies and systems, manufacturers can ensure that their products consistently meet or exceed expectations, while documentation and traceability systems provide the evidence needed to verify compliance. The next section will explore emerging trends and challenges that will shape the future of the fastener industry beyond 2025.

Future Trends and Challenges in the Fastener Industry

As we navigate through 2025, the fastener industry stands at a fascinating intersection of traditional engineering principles and cutting-edge innovation. This section explores the emerging trends and challenges that are reshaping the landscape of fastener technology, manufacturing, and application, providing insights into what lies ahead for this essential but often overlooked sector.

Smart Fasteners and IoT Integration

The integration of digital intelligence into fasteners represents perhaps the most transformative trend in the industry, creating components that not only join materials but actively monitor and report on their condition and environment.

Sensor-Embedded Fastening Systems

Fasteners are evolving from passive to active components through the integration of sensing capabilities:

- Load-monitoring fasteners incorporate miniaturized strain gauges or piezoelectric elements that continuously measure and report the forces acting on critical connections, enabling real-time verification of proper preload and early detection of potential joint failures.

- Temperature-sensing fasteners monitor thermal conditions in applications where heat can affect joint integrity or indicate potential problems in surrounding systems, such as overheating bearings or electrical connections.

- Vibration detection capabilities allow fasteners to serve as distributed monitoring networks in structures and machinery, identifying unusual vibration patterns that might indicate developing problems before they lead to failures.

- Corrosion monitoring systems embedded in fasteners can detect the early stages of corrosion through electrochemical sensors, providing alerts before structural integrity is compromised.

Wireless Communication and Data Integration

Smart fasteners require communication capabilities to deliver their data to monitoring systems:

- Low-power wireless protocols such as Bluetooth Low Energy (BLE), LoRaWAN, and specialized industrial IoT standards enable fasteners to transmit data without requiring wired connections or frequent battery replacement.

- Energy harvesting technologies including piezoelectric, thermal, and RF energy capture allow smart fasteners to generate their own power from environmental conditions, eliminating batteries entirely in many applications.

- Mesh networking capabilities enable fasteners to relay data from one to another, extending range and providing redundancy in large structures or complex assemblies.

- Edge computing integration allows preliminary data processing directly at the fastener level, reducing bandwidth requirements and enabling faster response to critical conditions.

Predictive Maintenance Applications

The data provided by smart fasteners is transforming maintenance strategies across industries:

- Real-time joint health monitoring enables condition-based maintenance rather than scheduled interventions, optimizing maintenance resources while improving safety and reliability.

- Failure prediction algorithms analyze patterns in fastener data to forecast potential issues before they occur, allowing planned interventions that minimize downtime and secondary damage.

- Digital twin integration incorporates fastener data into comprehensive virtual models of structures and machinery, enhancing simulation accuracy and enabling sophisticated what-if analyses for maintenance planning.

- Maintenance automation systems can use fastener data to dispatch robots or guide human technicians directly to developing problems, streamlining inspection and repair processes.

Sustainability Initiatives and Eco-Friendly Solutions

Environmental considerations have moved from peripheral concerns to central drivers of innovation in the fastener industry, with sustainability initiatives influencing everything from material selection to end-of-life management.

Sustainable Material Development

Materials research is increasingly focused on reducing environmental impact without compromising performance:

- Bio-based polymers derived from renewable resources are replacing petroleum-based plastics in non-structural fastener applications, with ongoing research aimed at expanding their use to more demanding environments.

- Recycled content alloys have overcome previous limitations through advanced processing techniques, enabling the use of high percentages of recycled material even in critical fastener applications.

- Carbon footprint optimization has become a standard consideration in material selection, with manufacturers developing comprehensive lifecycle assessments to guide material choices.

- Rare element reduction strategies minimize the use of scarce or environmentally problematic elements in fastener alloys and coatings, improving long-term sustainability.

Design for Disassembly and Recycling

Fastener design increasingly considers the entire product lifecycle, including eventual disassembly and material recovery:

- Reversible fastening systems enable non-destructive disassembly at end of life, preserving both the fasteners and joined components for reuse or efficient recycling.

- Material identification features such as embedded RFID tags or standardized marking systems facilitate automated sorting during recycling processes.

- Mono-material approaches reduce the number of different materials in fastening systems, simplifying separation and recycling while eliminating problematic material combinations.

- Degradable temporary fasteners designed for packaging and other short-term applications break down safely after use, reducing waste and contamination in recycling streams.

Carbon Footprint Reduction Strategies

Manufacturers are implementing comprehensive approaches to reduce the carbon impact of fastener production:

- Energy-efficient manufacturing processes minimize carbon emissions during production, with technologies such as electric induction heating replacing fossil fuel-based systems.

- Localized production networks reduce transportation emissions by manufacturing fasteners closer to their point of use, enabled by more flexible, automated production systems.

- Renewable energy adoption is accelerating across the industry, with many manufacturers committing to 100% renewable electricity for their operations.

- Carbon offset programs address emissions that cannot be eliminated directly, with fastener manufacturers investing in verified projects that remove or prevent carbon emissions elsewhere.

Global Supply Chain Resilience and Reshoring

Recent global disruptions have highlighted vulnerabilities in fastener supply chains, driving significant changes in sourcing strategies and manufacturing footprints.

Supply Chain Diversification

Dependency on single sources or regions has proven risky, leading to new approaches to supply chain management:

- Multi-region sourcing strategies balance cost efficiency with risk mitigation by maintaining production capabilities across different geographic areas.

- Supplier development programs help build capacity and capabilities in new regions, expanding the available supplier base while ensuring quality and performance standards are met.

- Strategic inventory management has evolved beyond just-in-time approaches to incorporate risk-based buffer stocks of critical fasteners, protecting against supply disruptions.

- Alternative material qualifications provide options when primary materials become unavailable or prohibitively expensive, allowing rapid adaptation to supply challenges.

Reshoring and Nearshoring Trends

Production is increasingly moving closer to end markets, reversing decades of globalization in fastener manufacturing:

- Advanced automation has reduced the labor cost advantage of offshore production, making reshoring economically viable for many fastener types.

- Quality and compliance considerations favor local production where oversight and verification are simpler and more direct.

- Lead time reduction through local manufacturing provides competitive advantages in markets where responsiveness and customization are valued.

- National security and critical infrastructure concerns are driving reshoring of fastener production for defense, energy, and other strategic sectors.

Digital Supply Networks

Traditional linear supply chains are evolving into interconnected digital networks that enhance visibility, flexibility, and resilience:

- End-to-end visibility platforms provide real-time tracking of materials and components throughout the supply network, enabling proactive management of potential disruptions.

- Digital marketplaces connect buyers directly with multiple potential suppliers, reducing dependency on established supply relationships and enabling rapid sourcing alternatives when needed.

- Additive manufacturing networks can produce certain fasteners on demand close to the point of use, providing a digital inventory backup for critical components.

- Blockchain-based traceability systems ensure the authenticity and compliance of fasteners throughout complex supply networks, reducing quality and regulatory risks.

Miniaturization and High-Precision Fastening Requirements

The continuing trend toward smaller, lighter, and more densely packed products is driving demand for fasteners that maintain performance despite dramatic size reductions.

Micro and Nano-Fastening Solutions

As products shrink, fasteners must follow suit while maintaining their essential functions:

- Sub-millimeter fasteners for electronics and medical devices require extraordinary precision in both design and manufacturing, with tolerances measured in microns rather than millimeters.

- Alternative joining methods such as micro-welding, adhesive bonding, and mechanical interlocking are increasingly combined with traditional fastening approaches in miniaturized applications.

- Specialized installation tools have evolved to handle these tiny components with the necessary precision and care, often incorporating computer vision and robotics for reliability.

- Material innovations address the unique challenges of micro-fasteners, where surface effects and material properties can behave differently than at conventional scales.

Precision Assembly Technologies

The assembly processes for high-precision fastening have advanced significantly:

- Automated micro-assembly systems combine machine vision, precision robotics, and sophisticated control systems to install miniature fasteners with consistency impossible to achieve manually.

- Torque control at micro-scales requires specialized approaches that account for the different physics of small fasteners, where traditional torque-tension relationships may not apply.

- Non-contact installation methods such as magnetism or ultrasonics can position and secure micro-fasteners without physical tools that might damage delicate components.

- In-process verification systems confirm proper installation of each fastener, critical when visual inspection becomes impractical due to size or accessibility limitations.

Integration with Printed Electronics and Flexible Substrates

Fastening technology is adapting to the unique requirements of emerging electronic form factors:

- Flexible circuit fastening solutions accommodate movement and bending while maintaining reliable electrical and mechanical connections.

- Direct integration with printed electronics blurs the line between fastener and circuit, with conductive fasteners serving both joining and electrical functions.

- Temperature-sensitive assembly techniques protect delicate electronic components during fastener installation, avoiding thermal damage to surrounding materials.

- Reworkable connections enable repair and component replacement in densely packed electronic assemblies, extending product life and reducing electronic waste.

Regulatory Changes and Compliance Challenges

The regulatory landscape affecting fasteners continues to evolve, with increasing focus on safety, environmental impact, and material restrictions.

Material Restriction and Substitution

Regulations limiting the use of hazardous substances continue to expand in scope and stringency:

- RoHS and REACH compliance has become more complex with the addition of new substances to restricted lists, requiring ongoing vigilance and occasional reformulation of fastener materials and coatings.

- Heavy metal elimination efforts continue to target remaining applications of lead, cadmium, hexavalent chromium, and other toxic metals in specialized fasteners and coatings.

- PFAS restrictions are affecting certain lubricating coatings used on fasteners, driving the development of fluorine-free alternatives with comparable performance.

- Nanomaterial regulations are emerging to address potential risks of engineered nanomaterials used in advanced fastener coatings and composites, adding new compliance requirements.

Harmonization of International Standards

The global nature of manufacturing has increased pressure for consistent standards across regions: