Metal Parts for Automotive, Aerospace, and Medical Industries: What You Need to Know

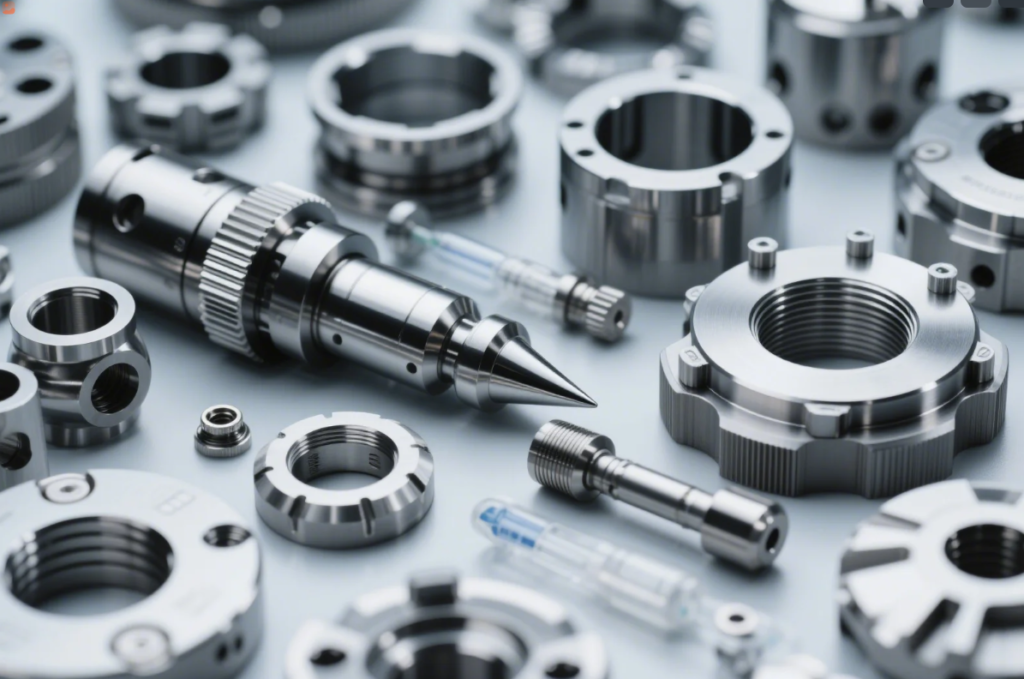

Metal parts used in aerospace, automotive, and medical industries must meet strict standards. Each industry demands specific materials, tolerances, and manufacturing processes.

This guide explains what metals are used, how parts are made, and what buyers should consider when sourcing components for critical sectors.

Working with the wrong supplier or materials can lead to regulatory failures, delays, or safety issues. Learn how to choose the right processes and certifications for your project.

What Metals Are Essential for Aerospace Parts?

The aerospace industry demands strong, lightweight metals that can survive high stress and extreme environments.

Titanium, aluminum alloys, and stainless steels are the most vital metals used in aerospace parts due to their strength-to-weight ratios and corrosion resistance.

Common Aerospace Metals

| Metal | Key Property | Application |

|---|---|---|

| Titanium (Grade 5) | High strength, light weight | Jet engines, airframes, landing gear |

| Aluminum 7075 | High strength-to-weight, machinable | Wings, fuselage, brackets |

| Stainless Steel 17-4 | Corrosion-resistant, heat-tolerant | Fasteners, turbine blades |

| Inconel | Extreme temperature tolerance | Exhaust systems, jet propulsion |

🔗 More info on NASA aerospace metal standards and ASM aerospace materials.

At Prime, we produce machined and stamped aerospace parts with full traceability and AS9100-aligned processes.

What Sheet Metal Is Used in the Automotive Industry?

Automotive sheet metal needs to be formable, weldable, and cost-effective—while still protecting occupants.

Mild steel, high-strength steel, aluminum, and stainless steel are widely used in vehicle bodies, frames, and reinforcements.

Automotive Metal Grades

| Metal Type | Example Use | Benefits |

|---|---|---|

| Mild Steel (CR4) | Body panels, frames | Easy to stamp and weld |

| HSLA Steel | Door beams, chassis rails | Higher strength, lighter weight |

| Aluminum 6000 series | Hoods, doors, bumper systems | Light weight, corrosion resistant |

| Stainless Steel 409 | Exhaust systems, mufflers | Heat and corrosion resistance |

🔗 For detailed specs, see WorldAutoSteel or SAE materials handbook.

We support automotive suppliers with fast-turn CNC and stamping parts—from prototype brackets to large sheet assemblies—with full PPAP documentation.

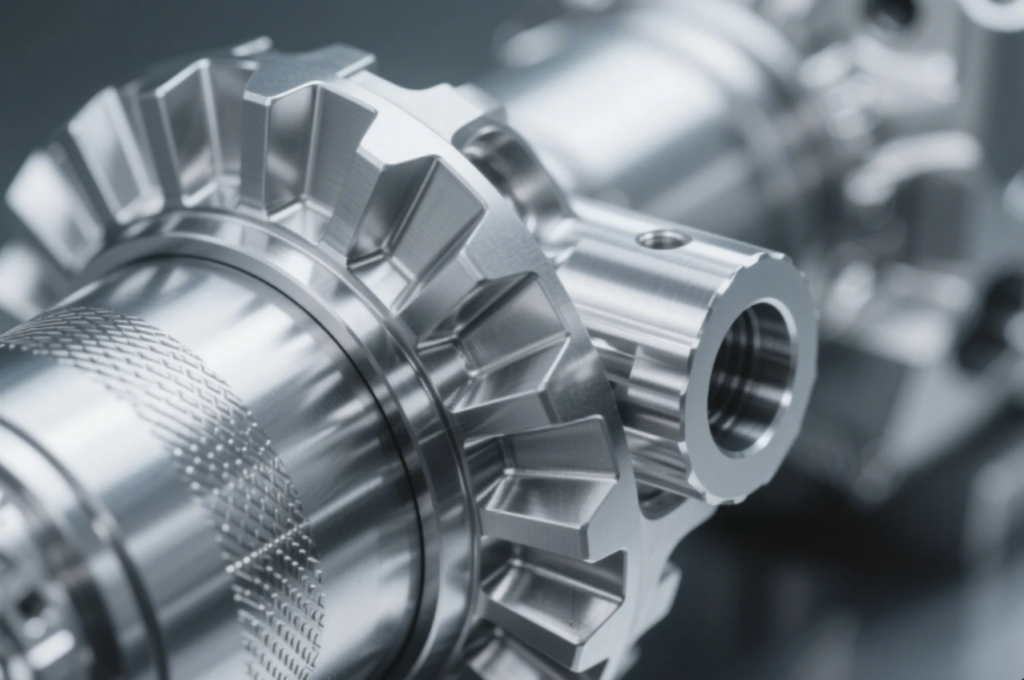

What Is Aerospace Sheet Metal Fabrication?

Aerospace sheet metal must be formed to extreme accuracy, often under tight FAA or EASA standards.

It involves forming, cutting, and joining lightweight metals like aluminum or titanium to build aircraft skins, ribs, and supports.

Key Processes in Aerospace Sheet Metal Work

| Process | Purpose |

|---|---|

| Forming (bending, rolling) | Shapes flat sheet into curved or angled panels |

| CNC Routing | Precision hole patterns for riveting |

| Heat Treating | Improves strength after forming |

| Riveting/Bonding | Joins sheets securely |

🔗 Check Boeing Material Specifications (BMS) or EASA Part 21 regulations.

At Prime, we bend, rivet, and machine aerospace sheet metal parts to ±0.1 mm accuracy using certified processes. Parts include access panels, battery boxes, and mounting brackets.

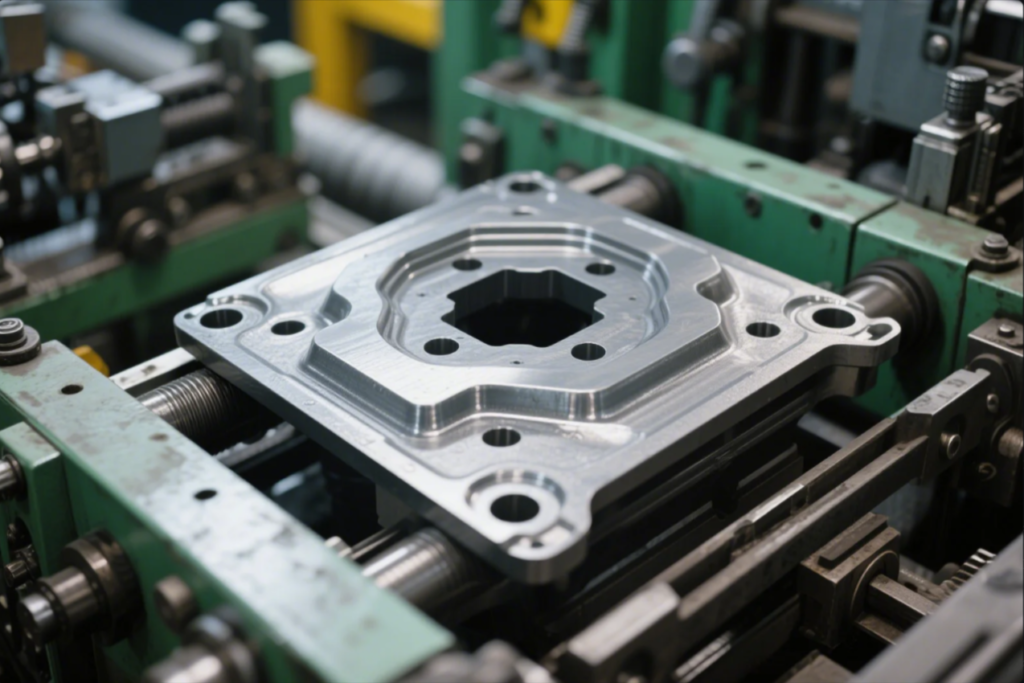

How Are Metal Car Parts Manufactured?

Most car parts are made using high-speed stamping and machining, depending on the part’s complexity and strength requirements.

Automotive metal parts are produced via stamping, CNC machining, die casting, and sometimes welding or laser cutting.

Common Methods for Car Part Manufacturing

| Method | Typical Parts | Notes |

|---|---|---|

| Stamping | Brackets, mounts, door frames | Fast and cost-efficient in high volume |

| CNC Machining | Sensor housings, engine components | Precision parts for low–mid volume |

| Die Casting | Transmission parts, housings | Ideal for complex, high-volume parts |

| Welding + Assembly | Subframes, support structures | Joins multiple stamped parts |

🔗 Read Automotive Manufacturing Trends at McKinsey.

At Prime, we combine all these processes under one roof. Our automotive clients include EV startups and Tier-2 suppliers across North America and Europe.

FAQs

Q1: What certifications should my metal parts supplier have for aerospace or medical?

Look for ISO 9001, IATF 16949 (automotive), or AS9100 (aerospace). Medical parts may require ISO 13485 and RoHS compliance.

Q2: Can aluminum be used in medical applications?

Yes, but it should be anodized or coated for bio-compatibility. Stainless steel is more common for implants and surgical tools.

Q3: What surface finishes are used for automotive or aerospace parts?

Anodizing, powder coating, passivation, electropolishing, and e-coating are all common, depending on the part.

Q4: Can one supplier handle all three industries?

Yes, if they have proper certifications, material traceability, and multi-process capabilities—like Prime.

Q5: What tolerances are standard in aerospace vs automotive?

Aerospace often requires ±0.01 mm to ±0.05 mm. Automotive uses ±0.05 mm to ±0.2 mm for stamped parts.

Conclusion

Each industry—aerospace, automotive, and medical—has its own requirements for materials, finishes, and tolerances. Choose the right supplier to meet both performance and compliance needs.

📩 Need CNC, stamping, or welding for your high-spec metal parts?

Email: [email protected]

🌐 Website: https://primecustomparts.com/

We offer ISO-certified, industry-grade manufacturing and ship globally. Trusted by engineers and OEMs for 20+ years.