Precision Metal Stamping Parts & Custom Components

Delivering High-Quality Custom Metal Stamping Solutions Since 1993

Quick Navigation

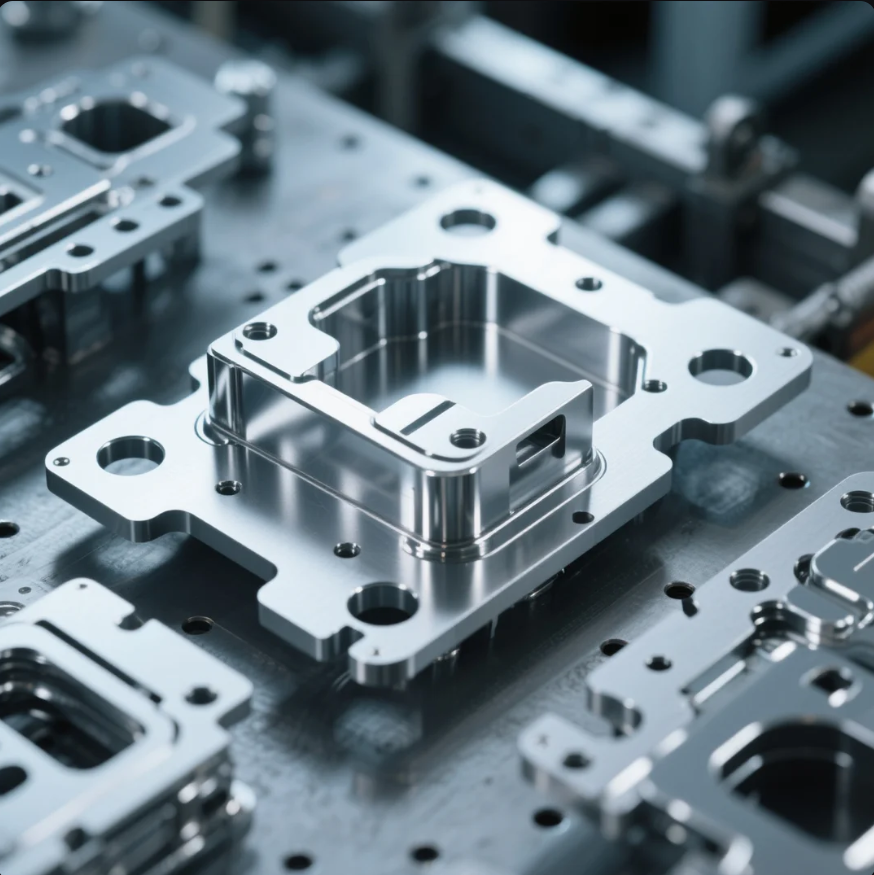

Metal Stamping Process: Precision Engineering at Scale

What is Metal Stamping?

Metal stamping is a sophisticated manufacturing process that transforms flat sheet metal into precise, three-dimensional components using specialized tools and presses. This high-efficiency process involves cutting, forming, and shaping metal through techniques such as blanking, punching, bending, embossing, and deep drawing. At Prime Custom Parts, our advanced metal stamping capabilities deliver components with exceptional dimensional accuracy, surface finish, and structural integrity for applications across diverse industries.

Metal Stamping Process Steps

1. Design & Engineering

Our engineering team works closely with clients to optimize designs for manufacturability, cost-efficiency, and performance. Using advanced CAD/CAM software, we develop precision tooling designs that ensure consistent quality across production runs.

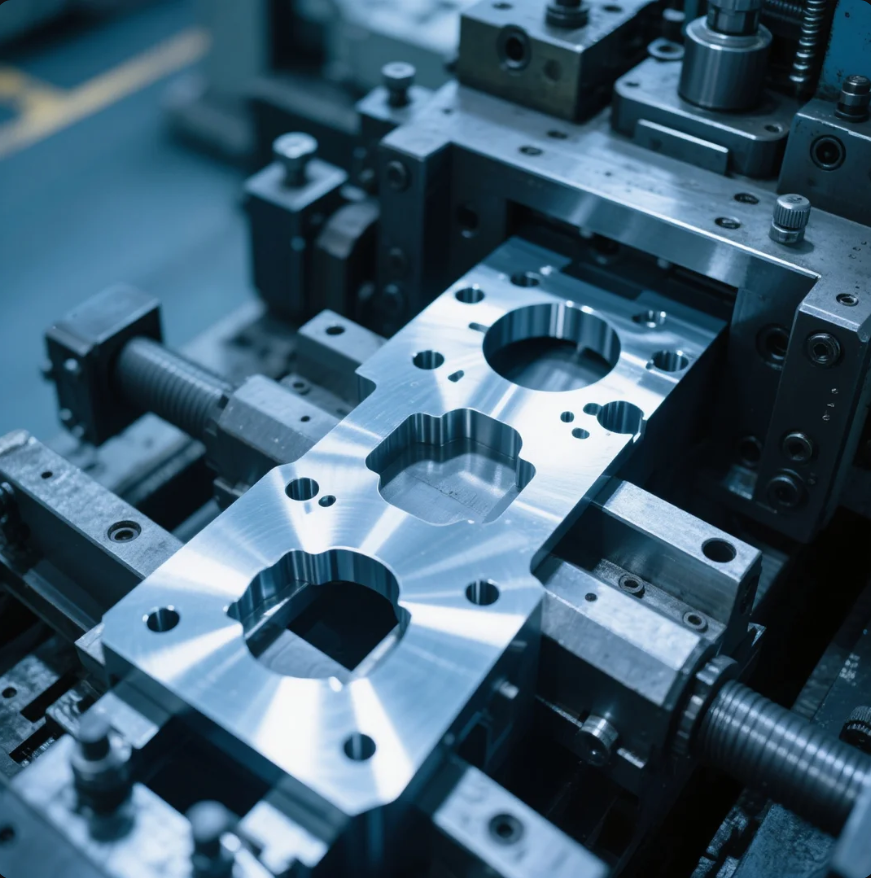

2. Tooling Development

We create custom dies and tooling using premium tool steel and precision machining. Our tooling capabilities include progressive dies, compound dies, and transfer dies designed for optimal performance and longevity.

3. Material Selection

Based on application requirements, we select the optimal material from our extensive inventory of premium metals, including various grades of stainless steel, carbon steel, aluminum alloys, copper, brass, and specialty alloys.

4. Stamping Production

Using hydraulic and mechanical presses ranging from 5 to 200 tons, we perform precision stamping operations including blanking, piercing, forming, drawing, and coining to create components with tight tolerances.

5. Secondary Operations

When required, we perform additional processes such as deburring, tapping, countersinking, heat treatment, plating, and surface finishing to complete the manufacturing process.

6. Quality Inspection

Every production run undergoes rigorous quality control using advanced measurement equipment, ensuring components meet or exceed specifications before shipment.

Prime's Metal Stamping Capabilities

Equipment & Technology

- Press capacity: 5-200 tons

- Bed sizes up to 60" x 120"

- Progressive, compound, and transfer dies

- CNC-controlled feed systems

- Automated material handling

- In-line quality monitoring systems

Material Expertise

We process a wide range of materials with thicknesses from 0.1mm to 6.0mm:

- Stainless Steel: 304, 316, 430, 17-4 PH

- Carbon Steel: 1008, 1010, 1018, 1045, 1095

- Aluminum: 1100, 3003, 5052, 6061

- Copper Alloys: C110, C260, C272 (brass), phosphor bronze

- Specialty Alloys: Inconel, Monel, beryllium copper

- Plated Materials: Zinc, nickel, tin, silver

Production Capacity

- Prototype to high-volume production

- Annual capacity: over 50 million parts

- Minimum order quantity: 250 pieces

- Maximum order quantity: 1,000,000+ pieces

- Just-in-time delivery capabilities

- Inventory management programs available

Precision & Tolerances

- Standard tolerances: ±0.05mm (±0.002")

- Tight tolerances: ±0.025mm (±0.001")

- Flatness control: 0.1mm per 100mm

- Surface finish: 0.8-3.2 μm Ra

- Dimensional verification using CMM technology

- Material certification available

Metal Stamping Product Types

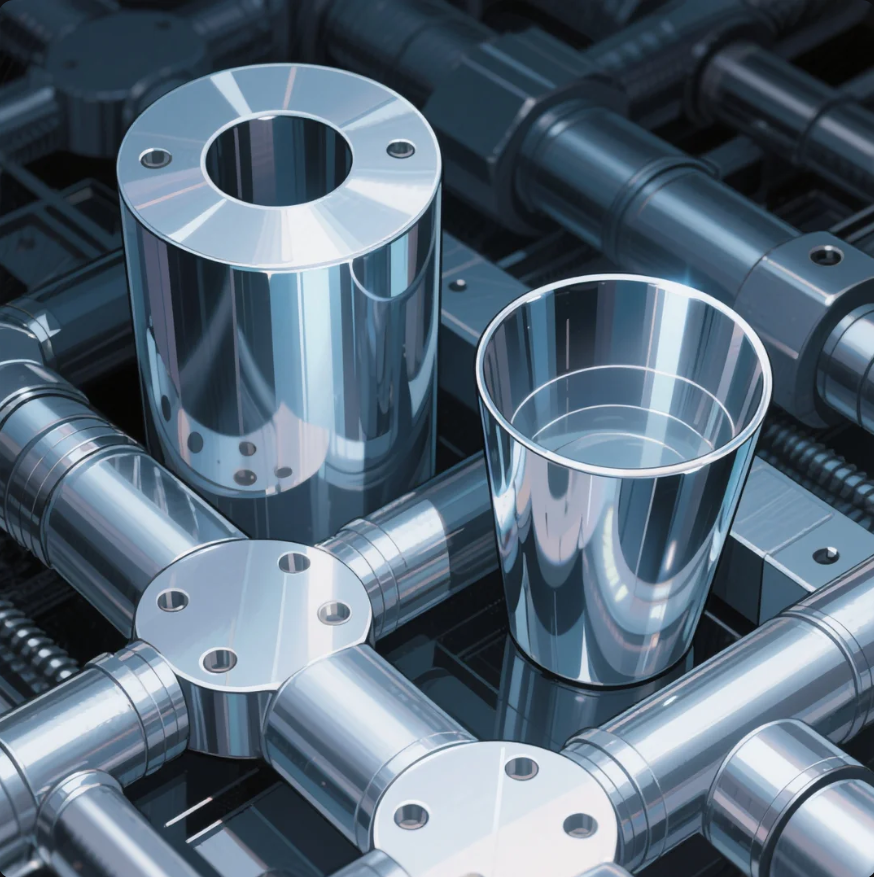

Deep Drawn Components

Specialized stamping process that forms sheet metal into cup-shaped, hollow components with significant depth. Our deep drawing capabilities produce seamless, strong parts with consistent wall thickness.

Common Applications:

- Enclosures and housings

- Canisters and containers

- Pressure vessels

- Filter components

- Appliance parts

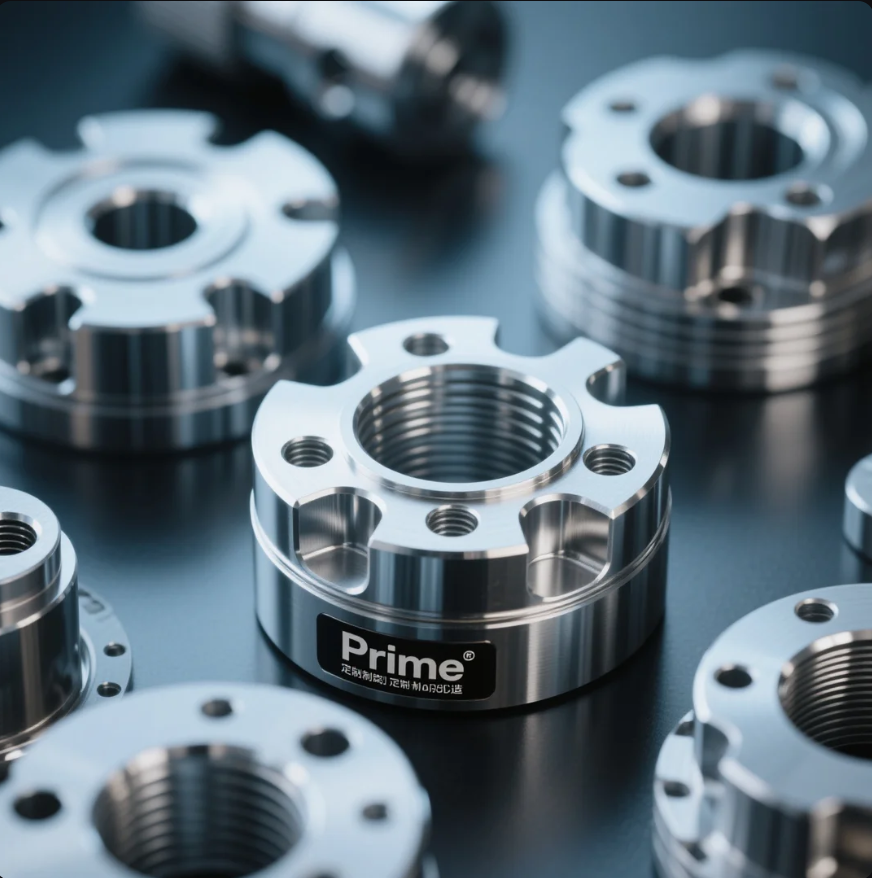

Custom Stamped Solutions

Tailored stamping solutions designed to meet your unique specifications. Our engineering team collaborates with you to develop custom components that optimize performance, cost, and manufacturability.

Common Applications:

- Proprietary product components

- Industry-specific parts

- Replacement for machined components

- Cost-reduction redesigns

- Multi-function assemblies

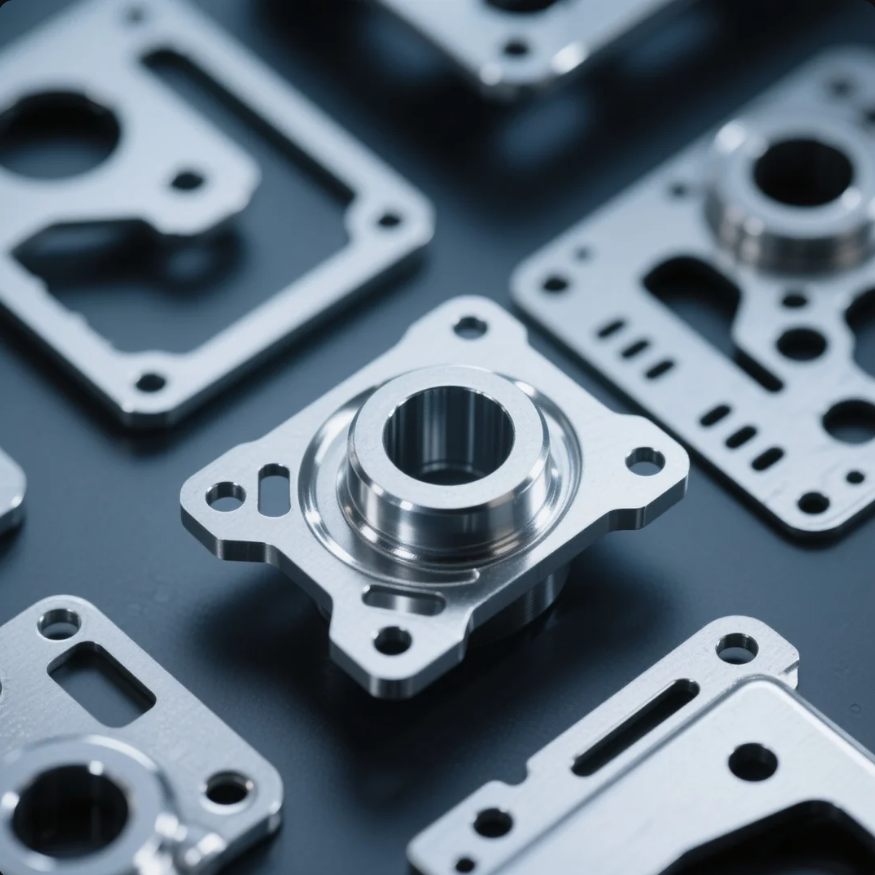

Precision Stamped Parts

High-accuracy components with tight tolerances for critical applications. Our precision stamped parts feature clean edges, consistent dimensions, and excellent repeatability across production runs.

Common Applications:

- Electrical connectors

- Electronic shields

- Medical device components

- Sensor housings

- Automotive electronics

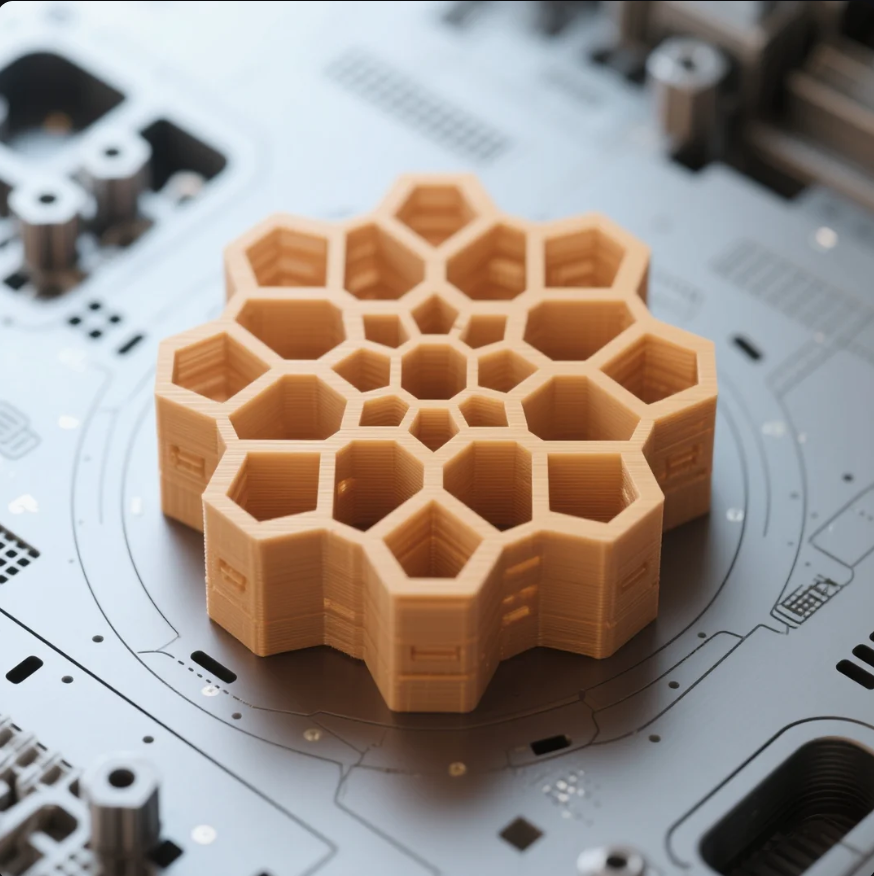

Progressive Die Stampings

Complex parts produced efficiently through multiple stations in a single progressive die. This process combines cutting, bending, and forming operations to create sophisticated components with minimal handling.

Common Applications:

- Automotive brackets and clips

- Multi-feature electrical components

- Complex structural elements

- Integrated assemblies

- Hardware components

Industry Applications

Automotive

Our metal stamping parts are integral to modern vehicles, providing durability and precision for critical components. We supply tier 1 and tier 2 automotive manufacturers with components that meet strict industry standards including IATF 16949 requirements.

Common Applications:

- Chassis components

- Transmission parts

- Brackets and mounting systems

- Sensor housings

- Electrical connectors

- Heat shields

Electronics

Precision is paramount in electronics manufacturing. Our stamped components deliver the tight tolerances and clean finishes required for reliable electronic assemblies, from consumer devices to industrial equipment.

Common Applications:

- EMI/RFI shields

- Terminal connectors

- Heat sinks

- Battery contacts

- Switch components

- Circuit board hardware

Medical Devices

The medical industry demands components with impeccable quality and consistency. Our ISO 13485 compliant processes ensure stamped parts meet the exacting standards required for medical devices and equipment.

Common Applications:

- Surgical instrument components

- Implantable device parts

- Diagnostic equipment components

- Medical device housings

- Fluid delivery system parts

- Sterilization tray components

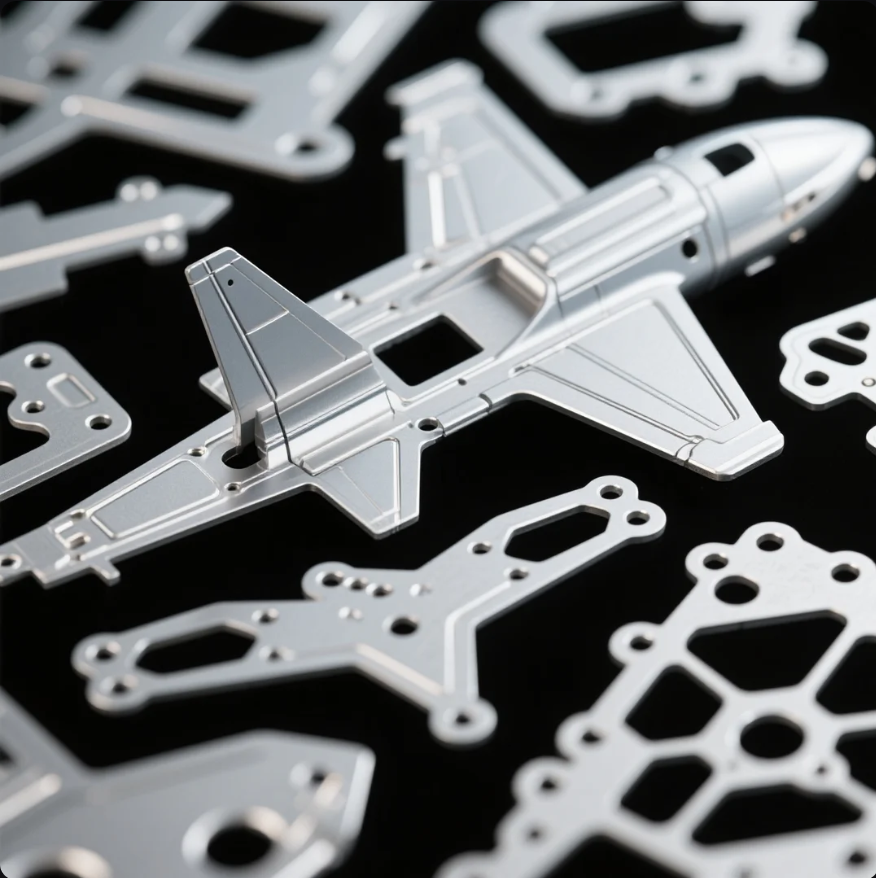

Aerospace

Aerospace applications require components that combine light weight with exceptional strength and reliability. Our aerospace-grade stamped parts meet AS9100 standards and provide consistent performance in demanding environments.

Common Applications:

- Structural brackets

- Interior component hardware

- Avionics housings

- Fuel system components

- Electrical connectors

- Control system elements

Industrial Equipment

Industrial machinery relies on robust, precision-manufactured components to ensure reliable operation in demanding environments. Our stamped parts deliver the durability and performance needed for continuous industrial use.

Common Applications:

- Pump and valve components

- Conveyor system parts

- Electrical enclosures

- Motor housings

- Fastening systems

- Control panel elements

Consumer Products

Consumer goods manufacturers rely on our stamped components for products that combine aesthetics with functionality. We deliver parts that enhance product performance while meeting cost targets for competitive markets.

Common Applications:

- Appliance components

- Hardware and fixtures

- Decorative elements

- Enclosure parts

- Mounting brackets

- Functional mechanisms

Quality Assurance & Certifications

At Prime Custom Parts, quality is integrated into every step of our manufacturing process. Our comprehensive quality management system ensures consistent excellence in all metal stamping components we produce.

Quality Control Process

Our multi-stage quality control process includes:

- Incoming material verification and certification

- First article inspection (FAI)

- In-process statistical process control (SPC)

- Dimensional verification using coordinate measuring machines (CMM)

- Surface finish and visual inspection

- Final quality audit before shipment

Testing Capabilities

- Material composition analysis

- Hardness testing

- Tensile strength testing

- Coating thickness measurement

- Salt spray corrosion testing

- Functional testing as required

Certifications

- ISO 9001:2015 Certified

- ISO 13485 Compliant (Medical)

- IATF 16949 Compliant (Automotive)

- RoHS Compliant

- REACH Compliantg

Our Quality Commitment

Prime Custom Parts maintains stringent quality standards through our comprehensive quality management system. Every metal stamping project undergoes rigorous inspection using advanced measurement equipment, ensuring dimensional accuracy to ±0.05mm and consistent surface finish quality. Our ISO 9001:2015 certified processes guarantee reliable, high-performance components that meet or exceed industry specifications. With detailed documentation and traceability for every production run, we provide complete confidence in the quality and consistency of our metal stamping parts.

Why Choose Prime Custom Parts for Metal Stamping

Since 1993, we've been delivering exceptional metal stamping solutions to clients worldwide. Our three decades of experience translate into expert guidance, optimized designs, and reliable manufacturing processes for your projects.

Our team of experienced engineers works closely with you from concept to production, optimizing designs for manufacturability, cost-efficiency, and performance. We provide design assistance, material selection guidance, and tooling development expertise.

With established logistics networks and international shipping expertise, we deliver metal stamping parts to clients worldwide with reliability and efficiency. Our global supply chain management ensures timely delivery regardless of your location.

Beyond metal stamping, we offer a complete range of secondary operations and finishing services, providing a one-stop solution for all your component needs. From design to delivery, we handle every aspect of your project.

Our efficient production processes, material optimization techniques, and economies of scale allow us to offer competitive pricing without compromising quality. We work with you to identify cost-saving opportunities throughout the manufacturing process.

We pride ourselves on responsive communication, transparent project management, and dedicated customer support. Your dedicated project manager ensures smooth execution from initial quote to final delivery.

What Our Clients Say

Frequently Asked Questions About Metal Stamping

Is there a problem? If you can not find the answer here, please feel free to contact our professional team.

What are metal stamping parts?

Metal stamping parts are precision components manufactured by forming sheet metal using dies and presses. This process shapes flat metal sheets into specific geometries through techniques like blanking, punching, bending, and deep drawing. Metal stamping produces high-quality components with tight tolerances for industries including automotive, electronics, aerospace, and medical devices.

What materials can be used for metal stamping?

Metal stamping can utilize a wide range of materials including stainless steel (304, 316, 430), carbon steel, aluminum alloys (1100, 3003, 5052), copper, brass, bronze, beryllium copper, and specialty alloys like Inconel and Monel. The material selection depends on the application requirements such as strength, corrosion resistance, electrical conductivity, and cost considerations.

What are the advantages of metal stamping?

Metal stamping offers numerous advantages including high production efficiency, excellent repeatability, tight tolerances (±0.05mm), cost-effectiveness for high-volume production, minimal material waste, ability to create complex geometries, and consistent quality across production runs. These benefits make metal stamping ideal for industries requiring precision components at scale.

What industries use metal stamping parts?

Metal stamping parts are widely used across multiple industries including automotive (brackets, chassis components, transmission parts), electronics (connectors, shields, heat sinks), aerospace (structural components, brackets), medical devices (surgical instruments, implant components), appliances (housings, brackets, decorative elements), telecommunications (connectors, shields), and consumer products (hardware, decorative elements).

How does metal stamping compare to other manufacturing processes?

Compared to processes like CNC machining, metal stamping offers significantly higher production rates and lower per-unit costs for high-volume production. While CNC machining excels at producing complex, low-volume parts with extremely tight tolerances, stamping is more economical for larger quantities. Compared to casting, stamping typically produces parts with better dimensional accuracy and surface finish. The optimal manufacturing process depends on factors including production volume, material requirements, complexity, and tolerance specifications.

What is the typical lead time for metal stamping projects?

Lead times for metal stamping projects vary based on complexity, volume, and tooling requirements. Typical timelines include:

Tooling development: 2-8 weeks depending on complexity

First article samples: 1-2 weeks after tooling completion

Production runs: 2-4 weeks after sample approval

For repeat orders using existing tooling, production lead times can be as short as 1-2 weeks. Rush services are available for time-sensitive projects.

What is the minimum order quantity for metal stamping?

Our standard minimum order quantity is 250 pieces, though this can vary based on part complexity and tooling requirements. For high-volume production, we offer competitive pricing tiers starting at 1,000 pieces, with significant economies of scale at higher quantities. For prototype or low-volume needs before committing to stamping tooling, we recommend our CNC machining services as a cost-effective alternative.

How do you ensure the quality of metal stamped parts?

We maintain stringent quality control through our ISO 9001:2015 certified quality management system. Every production run undergoes comprehensive inspection including first article inspection, in-process statistical process control, and final verification using precision measurement equipment. Our quality assurance process ensures dimensional accuracy, material integrity, and surface finish quality meet or exceed specifications. We provide detailed quality documentation with each shipment, including material certifications and inspection reports as required.

Related Manufacturing Services

For complex geometries and ultra-precise tolerances, our CNC machining services complement our metal stamping capabilities.

When your project requires complex internal geometries or specialized alloys, our casting services provide the perfect solution.

Enhance the performance and appearance of your metal components with our comprehensive finishing services.

Streamline your supply chain with our integrated assembly services for complete component solutions.

Ready to Start Your Metal Stamping Project?

Contact our team today to discuss your requirements and receive a customized quote for your metal stamping needs.