Metal Stamping vs CNC Machining: Which is Best for Your Project in 2025?

Choosing between metal stamping and CNC machining in 2025 can be challenging. Both offer unique strengths—but only one truly fits your project.

This guide compares CNC and stamping based on cost, precision, volume, and flexibility. Make the right process decision for your custom metal components.

Many engineers and buyers face delayed production or budget issues due to the wrong choice. Read on to avoid costly missteps.

Is There a Future in CNC Machining?

CNC machining continues to thrive in aerospace, robotics, and medical sectors. It evolves with AI and Industry 4.0 integration.

CNC machining remains future-proof in 2025, supporting high-precision production across multiple industries.

Why CNC Will Dominate

| Trend | Impact |

|---|---|

| Smart factories | CNC integrates into IoT ecosystems |

| Multi-axis machining | Enables complex shapes in fewer setups |

| Additive-subtractive mix | 3D printing and CNC combine for design freedom |

| Global job growth | CNC jobs grow steadily (Source) |

Dive Deeper: Where CNC Is Headed

According to Modern Machine Shop, more companies now combine CNC with digital twins and simulation for faster iterations. Machine learning also helps predict maintenance schedules—saving downtime.

Autodesk Fusion 360 empowers engineers to directly convert 3D models to G-code. This speeds up design-to-prototype cycles in industries like EV and drone technology.

What Are the Disadvantages of Stamping?

Stamping excels in large quantities. But it falters on design flexibility and small batch efficiency.

Disadvantages include high initial tooling cost, long lead times, and inflexible design changes.

Common Stamping Limitations

- High die cost

- Long tooling development cycles

- Limited to 2D or shallow forms

- No good fit for fast-changing prototypes

Dive Deeper: When Stamping Fails

Stamping needs expensive dies and long setup times. According to Thomasnet, it’s only cost-effective for 10,000+ units.

Need curved enclosures or tapped holes? CNC is better. With Prime’s stamping services, we guide customers when stamping makes sense—and when CNC is smarter.

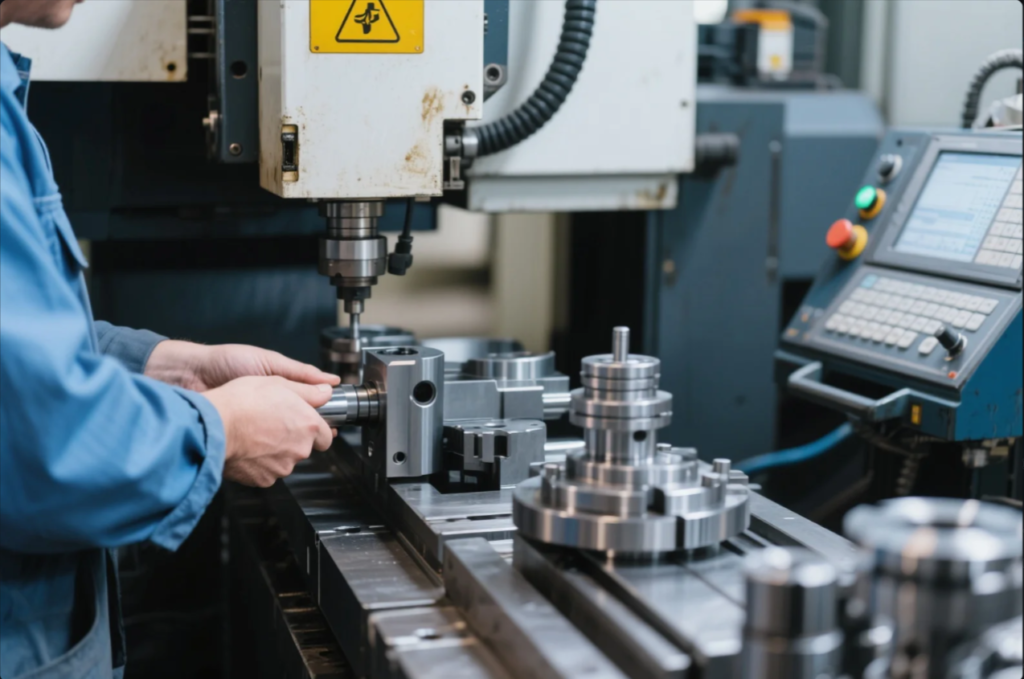

Why Do Engineers Like CNC Machining?

Engineers prioritize flexibility, precision, and fast iteration. CNC offers all three.

Engineers value CNC for its prototyping ease, accuracy, and broad material compatibility.

Engineer-Friendly Features

- ±0.01 mm tolerances

- Works with aluminum, steel, brass, plastics

- No die setup delays

- Easy design adjustments via Fusion 360

- Repeatable parts every time

Dive Deeper: Real-Time Engineering Advantage

With CNC, engineers can model and test new geometries daily. Software like SolidWorks links directly with CAM programs for seamless production.

At Prime, engineers send a STEP file, and we start production within 24 hours. No waiting on tooling. No miscommunication. Just instant action.

What Are Three Disadvantages of a CNC Machine?

Though CNC shines in precision, it has trade-offs in speed, cost, and upkeep.

Main disadvantages are higher cost per part, slower cycle time for simple parts, and technical maintenance needs.

CNC Weak Points

| Factor | Description |

|---|---|

| Higher per-unit cost | Less efficient than stamping for basic parts |

| Lower speed | Not ideal for 100K+ quantities |

| Technical setup | Requires skilled operators and calibration |

Dive Deeper: Knowing CNC’s Limits

CNC doesn’t scale cheaply for mass production. That’s why stamping dominates the automotive sector for flat, repetitive parts.

Metal Stamping vs CNC Machining. For example, if you’re producing 200,000 washers, stamping saves 60% over CNC. But for aerospace brackets or medical instruments? CNC wins every time.

Platforms like Xometry let buyers calculate both methods before deciding. At Prime, we offer the same transparency.

FAQs

Q1: Which is better for prototypes, CNC or stamping?

CNC. It’s faster, cheaper, and doesn’t require tooling.

Q2: When should I choose stamping over CNC?

For simple, high-volume parts with stable designs—like brackets or panels.

Q3: Can CNC handle plastic parts too?

Yes. CNC works with ABS, nylon, Delrin, and other engineering plastics.

Q4: How do I avoid poor quality in CNC parts?

Use certified suppliers like Prime and ensure they follow ISO 9001 protocols.

Q5: What industries rely heavily on CNC today?

Aerospace, defense, robotics, electronics, and medical sectors use CNC for high-spec parts.

Conclusion

Use metal stamping for flat, high-volume parts. Choose CNC machining for tight tolerances, small batches, or complex shapes.

Need help picking the right method?

📩 Email us at [email protected]

🌐 Explore: https://primecustomparts.com/

We provide expert advice, fast quotes, and precision-manufactured parts—all from our ISO-certified facility with 10+ production lines.