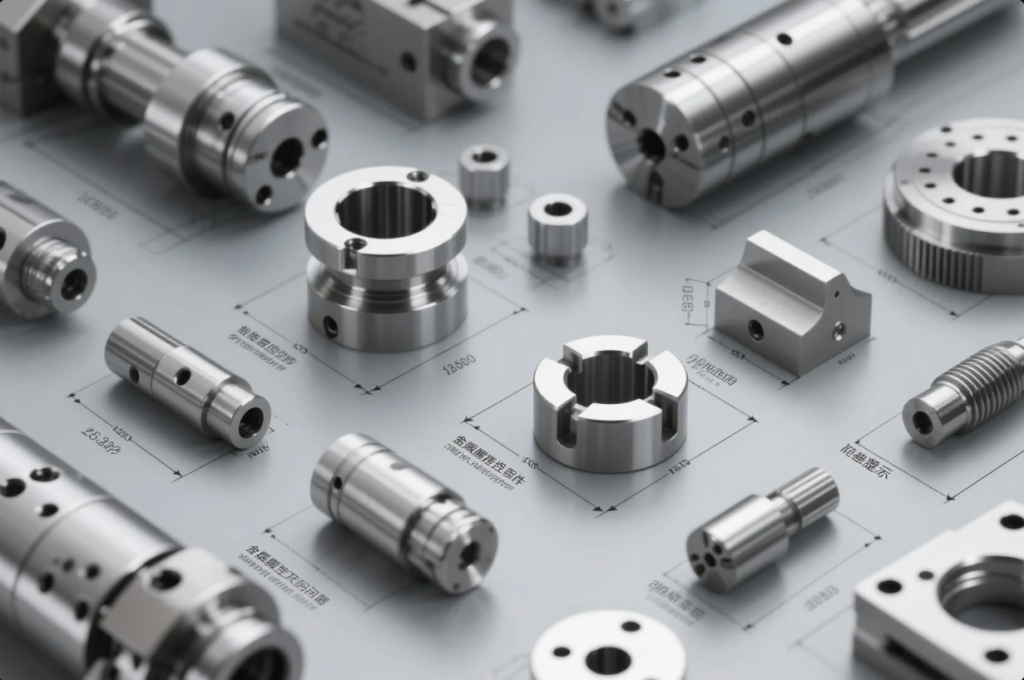

Multi‑Axis CNC Machining: Benefits for Complex Metal Parts?

Problem: Your parts have curves, angles, and internal features—but your supplier can’t machine them in one go.

Agitate: Multiple setups increase cost, time, and alignment errors.

Solve: Learn how multi‑axis CNC machining solves these issues and boosts manufacturing precision.

Snippet paragraph:

✔️ Multi‑axis CNC reduces setups and improves surface finish.

✔️ 5‑axis machining handles curves, holes, and undercuts in one run.

✔️ Learn differences between 3‑, 4‑, and 5‑axis machines.

✔️ See how CAM and fixture design affect cost and accuracy.

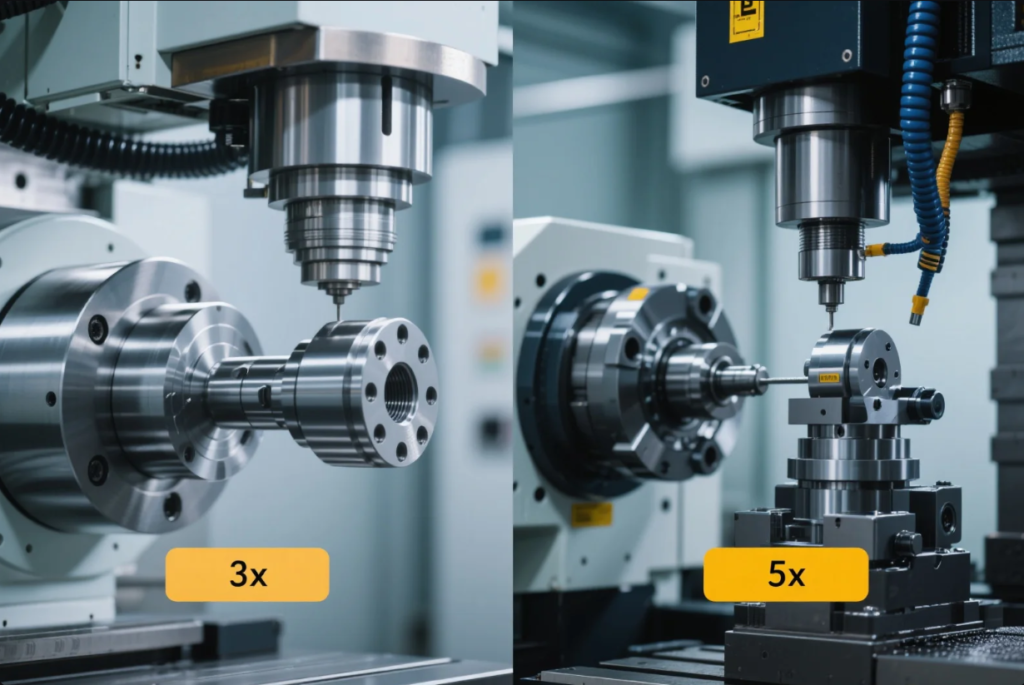

3‑Axis vs 4‑Axis vs 5‑Axis: Choosing the Right Machine

Choosing the right CNC machine is about more than just complexity—it’s about efficiency, cost, and finish quality.

| Machine Type | Axes Controlled | Best For | Limitations |

|---|---|---|---|

| 3‑Axis | X, Y, Z | Flat or prismatic parts | Needs multiple setups for angles |

| 4‑Axis | X, Y, Z + A (rotation) | Cylindrical parts, holes at angles | Limited access to 5 sides |

| 5‑Axis | X, Y, Z + A, B | Complex surfaces, undercuts, deep cavities | Higher cost, CAM complexity |

Example:

Using 5‑axis machining, an aluminum pump body with internal ports was finished in 2.5 hours, compared to 8 hours and four setups on a 3‑axis machine.

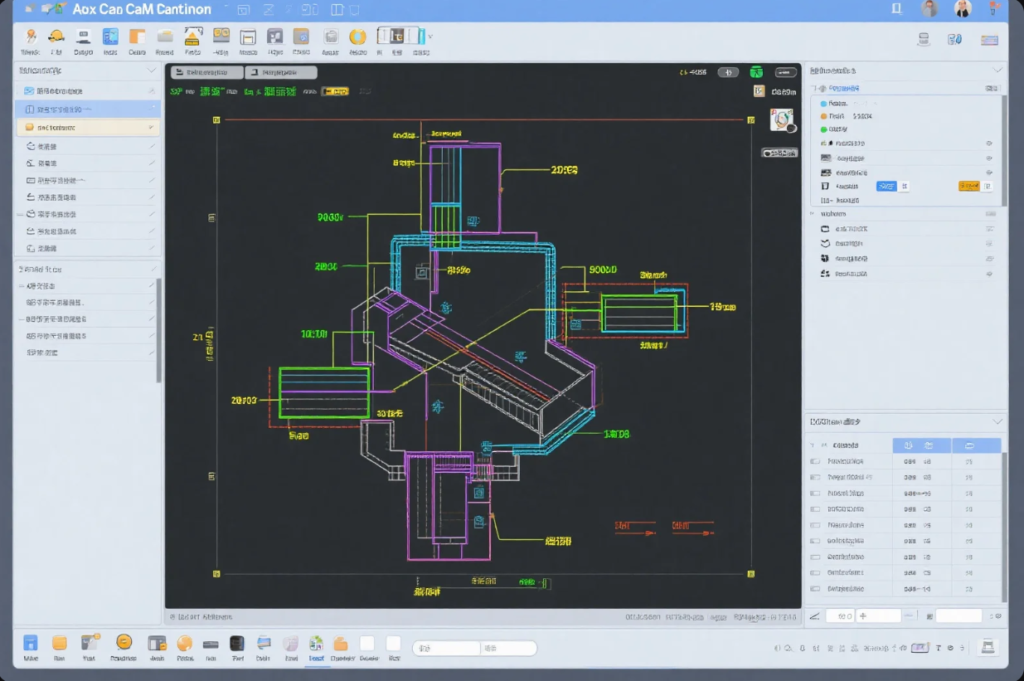

Programming Challenges and CAM Strategies

Multi-axis programming involves:

- Collision avoidance

- Tool angle optimization

- Dynamic feed control

- Simulation for toolpaths

| CAM Feature | Purpose | Ideal For |

|---|---|---|

| Swarf Cutting | Uses tool sidewall | Angled walls, turbine blades |

| Dynamic Toolpaths | Auto-adjust feed/speed | Uneven geometry, organic surfaces |

| Tool Axis Smoothing | Minimizes sudden orientation shifts | Freeform contours, mold cavities |

| Collision Checking | Prevents damage & crashes | Tight setups, 5-axis paths |

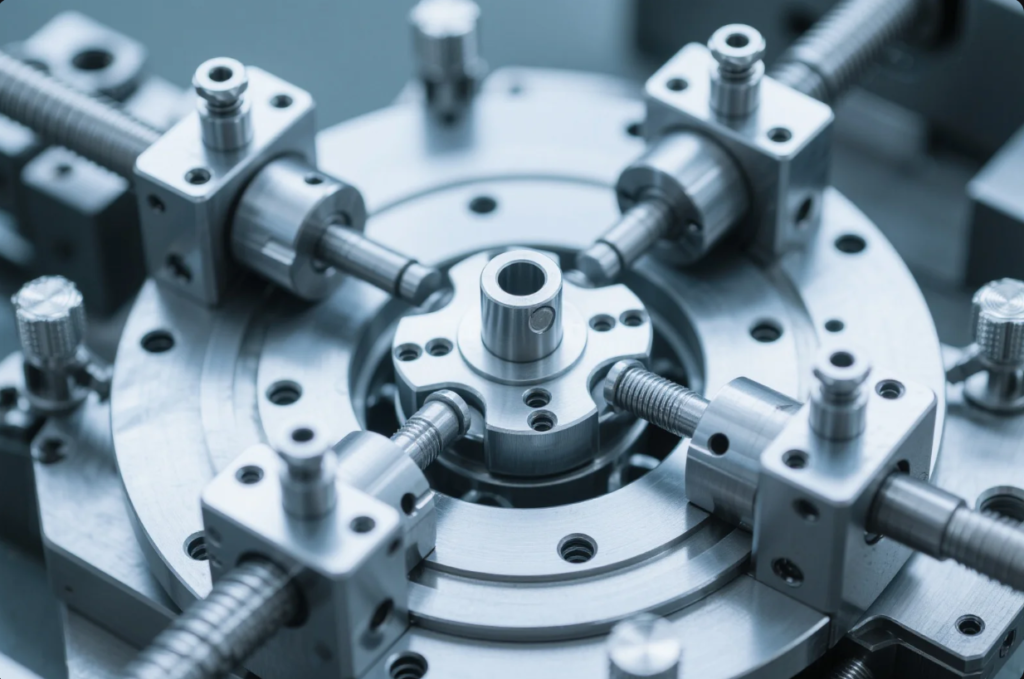

Fixture Design and Part Accessibility

Strong yet accessible fixturing is critical. Use:

- Self-centering vises for minimal obstruction

- Zero-point clamps for fast and accurate setup changes

- Tombstone fixtures for multiple parts per cycle

| Fixture Type | Best For | Features |

|---|---|---|

| Vise | Flat, blocky parts | Low-profile, fast setup |

| Rotary Fixture | 4-/5-axis rotary movement | Angled bores, round features |

| Vacuum Table | Thin or fragile parts | No mechanical pressure, good hold |

Fixturing for 5-Axis – Modern Machine Shop

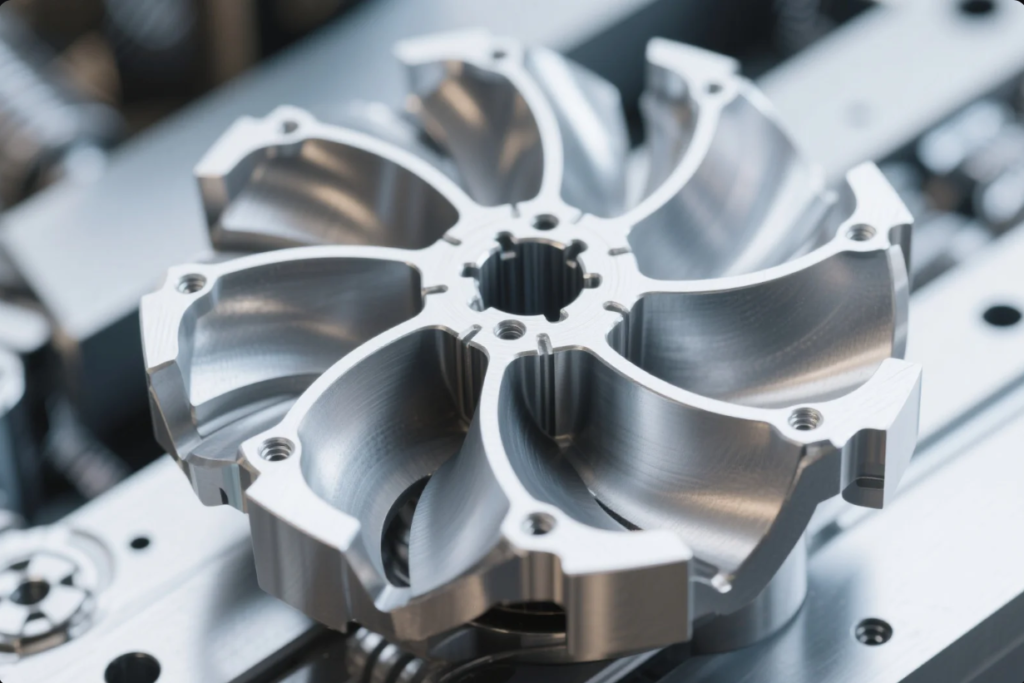

Typical Applications: Impellers, Housings, Complex Geometries

Multi-axis CNC machining is ideal for:

- Impellers (5-axis swarf cutting)

- Medical enclosures (small, multi-face machining)

- Aerospace ribs and brackets (multi-angle pocketing)

- Robotics joints (concentric and tapered bores)

| Application | Axis Required | Material | Challenges |

|---|---|---|---|

| Turbine Blisk | 5-axis | Inconel | Tool wear, precision |

| Robot Housing | 4/5-axis | Aluminum | Internal cuts, mounting flats |

| Mold Insert | 3/5-axis | Tool Steel | Surface finish, cooling lines |

How 5-Axis Enables Aerospace Parts

FAQs

Q1: Is 5-axis always better?

A: Only when part complexity or precision requires it. For simple flat parts, 3-axis is faster and cheaper.

Q2: Can I request simulation before machining?

A: Yes. Prime provides full CAM simulation with collision checks.

Q3: Is 4-axis enough for angled holes?

A: Yes for radial cuts. No for compound angles or simultaneous movement.

Q4: Does multi-axis increase part cost?

A: Slightly, but it reduces total cost by minimizing errors, setups, and lead time.

Q5: What file formats are supported?

A: STEP, IGES, Parasolid, STL for CAM; PDF or DXF for drawings.

Conclusion

Multi-axis CNC machining opens new possibilities for speed, quality, and part complexity. At Prime, we deliver:

- Precision parts on 3-, 4-, and 5-axis machines

- Full CAM simulation and expert programming

- Custom fixtures and fast global shipping

- ISO 9001 & AS9100 certified processes

📧 Ready to manufacture smarter?

Email: [email protected]

🌐 Website: https://primecustomparts.com